The basic purpose of conductive work surfaces is to

provide a surface that is free of static charge and also is

capable of removing the static charge from conductive

items placed on it. The total resistance to ground

determines the level of charge and rate at which it will be

drained. A resistance to ground of 1000 megohms or less is

required on an 8200 mat to drain a charge to a level of 100

volts or less in one second from a person or tote box

charged to 5KV (ref.1, 2).

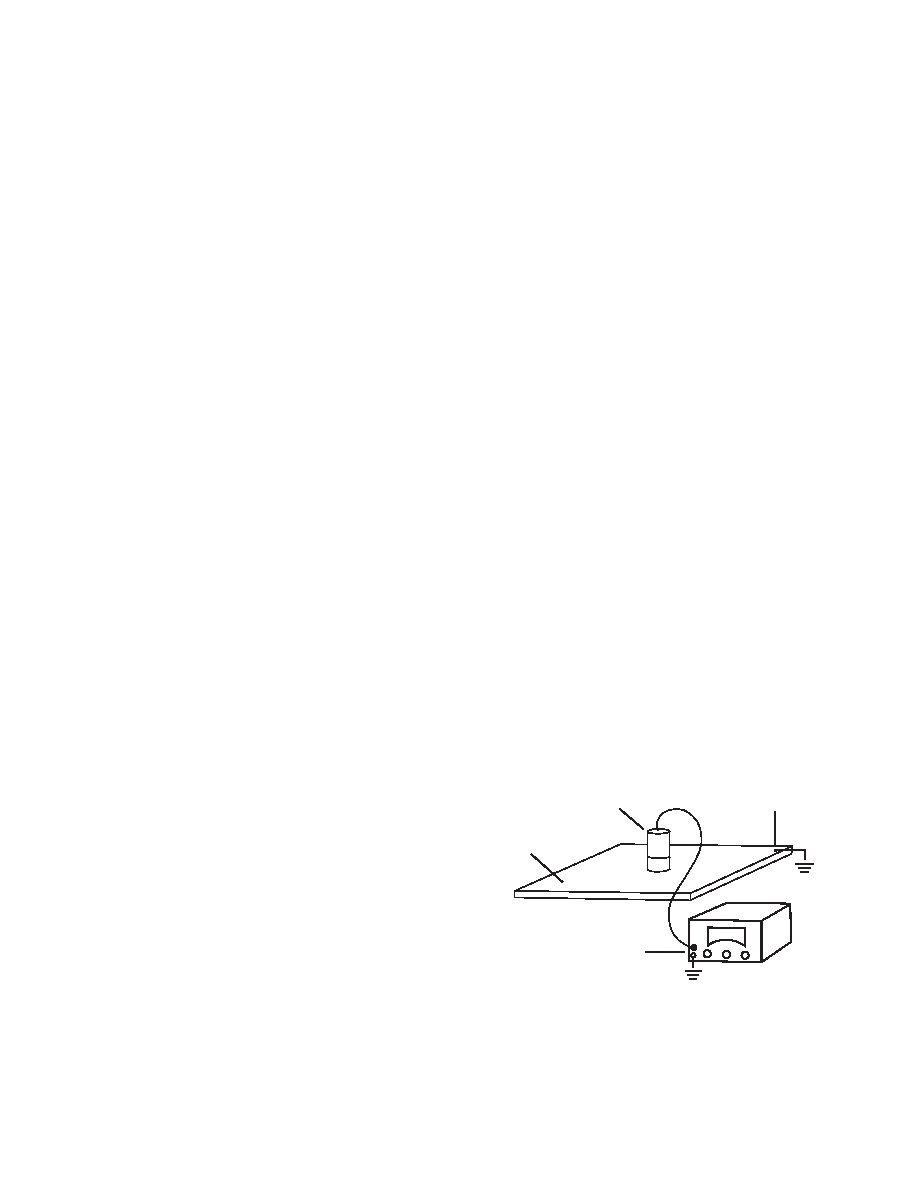

Resistance Measurement:

Measuring the resistance of the mat requires a high voltage

megohmmeter. The megohmmeter must have a test voltage

of 50-100 volts and a meter range of 0-1000 megohms. The

ground lead of the megohmmeter is attached to the ground

points of the mat. The other lead of megohmmeter is

attached to an electrode that is described in both ASTM F

150 and NFPA 56A paragraph 4-6.2.7(b).

The resistance to ground should be greater than 106

ohms and less than 109 ohms. if the resistance is less than

106 ohms, an alternate path to ground has been established

which bypasses the one megohm resistor in the ground

cord. If the resistance is greater than 109 ohms, the ground

connection has been interrupted.

Cleaning:

Mats should be periodically cleaned with a detergent and

water solution. To reduce the possibility of leaving a

residue, detergents (rather than soaps) should be used.

Powdered detergents such as Tide, Ajax, etc. should be

added to water at a 1-2% concentration, liquid detergents

such as Wisk, All, etc. at a 2-3% concentration, and

general purpose cleaners such as 409, Mr. Clean, etc. can

be used full strength.

Normally, only a cloth that is thoroughly wetted with the

detergent solution is needed to wipe off the mat; however,

hardened stains may require brushing with a semirigid

bristled brush. The wiping or brushing action should be in a

circular motion to ensure removal of the particles from the

surface depressions. Extremely soiled mats may require

several repeated cleanings with a water rinse between each

cleaning. The water rinse should consist of wetting a cloth

with clean water and wiping the surface to remove loosened

dirt and detergent.

The final step should be to use a cloth dampened with

isopropanol and wipe the mat to remove any organic

contamination as well as the residual detergent. Avoid

using excessive isopropanol because the bottom foam layer

will absorb the solvent and cause the mat to swell.

Regardless of the technique used to clean the mats, the

previously described resistance measurement should be

performed to verify that the mat is functional.

Note: Read all Health Hazard, Precautionary, and First Aid

statements found in the Material Safety Data Sheet (MSDS)

and/or product label of cleaning materials prior to handling

or use.

Reference:

1.

D. M. Yenni, Jr. "Basic Electrical Considerations in

the Design of a Static-Safe Work Environment", Proc.,

(NEPCON/WEST), March 1979, pp. 273-284.

2.

J. R. Huntsman, D. M. Yenni, Jr., "Test Methods for

Static Control Products", Proc., EOS/ESD Symposium

1982, pp. 94-109.

Maintenance of Static Control

Systems 8200 Mats

Technical Brief – July, 1983

No. 113

3

Megohmmeter

Table

Mat

NFPA 56A

Electrode

Ground

Connection