- 您現(xiàn)在的位置:買賣IC網 > PDF目錄22369 > 0.5-4A (J S T MFG CO LTD) 0.5 mm2, WIRE TERMINAL PDF資料下載

參數(shù)資料

| 型號: | 0.5-4A |

| 廠商: | J S T MFG CO LTD |

| 元件分類: | 終端 |

| 英文描述: | 0.5 mm2, WIRE TERMINAL |

| 文件頁數(shù): | 3/5頁 |

| 文件大小: | 387K |

| 代理商: | 0.5-4A |

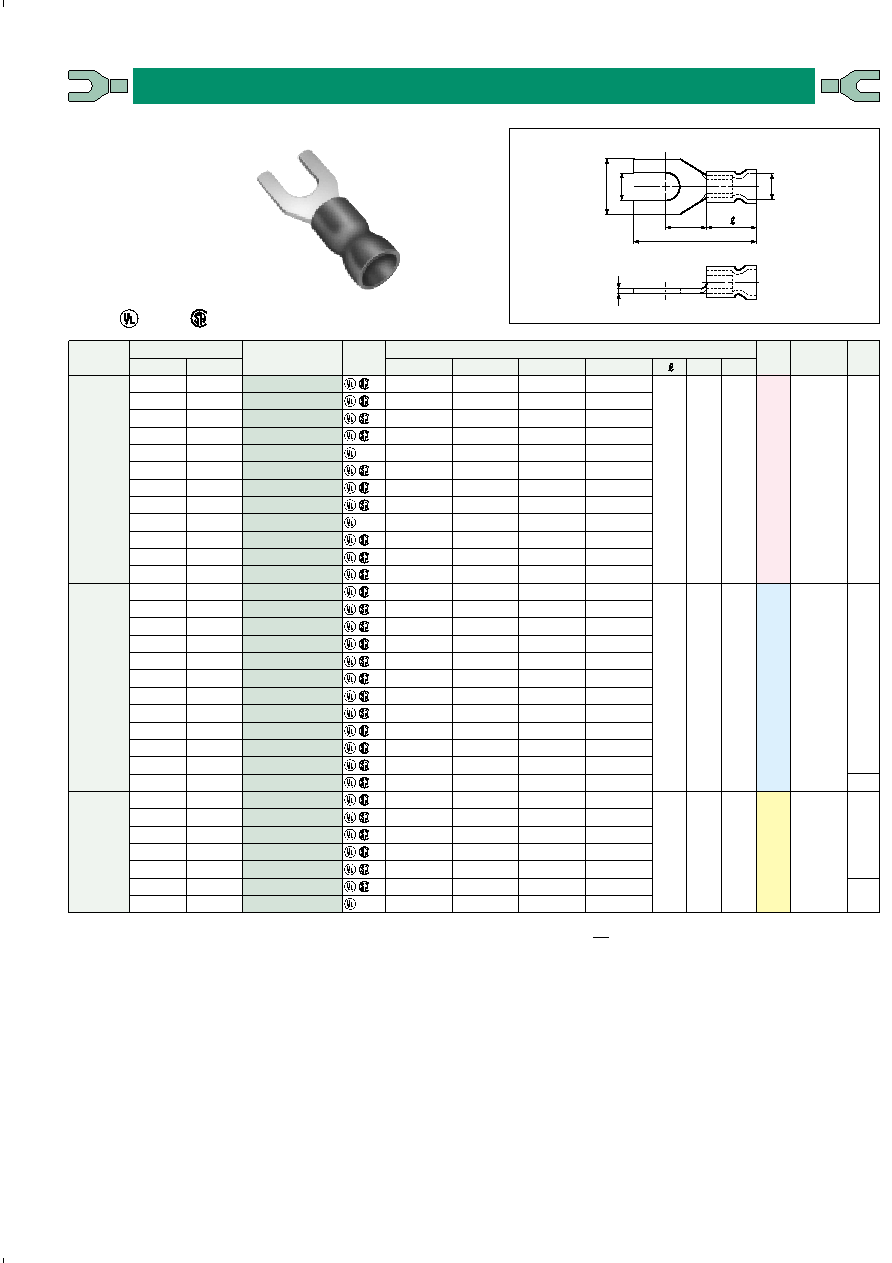

36

File No.:

E42024

LR20812

F

L

B

T

D

d

2

d2

BF

LT

American

Stud size

Part No.

Standard

Tool No.

Color

Qty/box

Dimensions mm (in.)

Metric

Applicable Wire

AWG#(mm2)

22 to 16

*(0.25 to

1.65)

16 to 14

(1.04 to

2.63)

12 to 10

(2.63 to

6.64)

3-4

5-6

8

10

1/4

3-4

5-6

8

10

1/4

5-6

8

10

1/4

5/16

3

3.5

4

5

6

3

3.5

4

5

6

3.5

4

5

6

8

FVX1.25-B3A

FVX1.25-N3A

FVX1.25-YS3A

FVX1.25-S3A

FVX1.25-P3A

FVX1.25-YS4A

FVX1.25-S4A

FVX1.25-4A

FVX1.25-S5A

FVX1.25-M5A

FVX1.25-5A

FVX1.25-6A

FVX2-N3A

FVX2-M3A

FVX2-YS3A

FVX2-S3A

FVX2-3A

FVX2-YS4A

FVX2-YM4A

FVX2-S4A

FVX2-4A

FVX2-M5A

FVX2-5A

FVX2-6A

FVX5.5-S3A

FVX5.5-3A

FVX5.5-S4A

FVX5.5-4A

FVX5.5-5A

FVX5.5-6A

FVX5.5-8A

3.2 (.126)

3.7 (.146)

4.3 (.169)

5.3 (.209)

6.4 (.252)

3.2 (.126)

3.7 (.146)

4.3 (.169)

5.3 (.209)

6.4 (.252)

3.7 (.146)

4.3 (.169)

5.3 (.209)

6.4 (.252)

8.4 (.331)

5.8 (.228)

6.2 (.244)

6.4 (.252)

7.2 (.284)

7.5 (.295)

6.4 (.252)

7.2 (.284)

8.5 (.335)

7.2 (.284)

8.5 (.335)

9.5 (.374)

12.0 (.472)

5.9 (.232)

6.0 (.236)

6.4 (.252)

7.2 (.284)

8.5 (.335)

6.4 (.252)

6.8 (.268)

7.2 (.284)

8.5 (.335)

9.5 (.374)

12.0 (.472)

7.2 (.284)

9.5 (.374)

8.5 (.335)

9.5 (.374)

13.5 (.532)

21.8 (.858)

21.4 (.843)

21.8 (.858)

21.4 (.843)

21.8 (.858)

28.0 (1.102)

21.8 (.858)

20.5 (.807)

21.4 (.843)

23.0 (.906)

22.8 (.898)

21.4 (.843)

23.0 (.906)

22.8 (.898)

28.0 (1.102)

26.7 (1.051)

32.7 (1.287)

6.3 (.248)

5.5 (.217)

6.3 (.248)

7.0 (.276)

6.3 (.248)

7.0 (.276)

11.0 (.433)

6.3 (.248)

5.0 (.197)

6.3 (.248)

6.5 (.256)

7.3 (.287)

6.3 (.248)

6.5 (.256)

7.3 (.287)

11.0 (.433)

7.5 (.295)

12.2 (.480)

14.0

(.551)

10.8

(.425)

10.8

(.425)

1.0

(.039)

YNT-1210S

YA-4

BCT-0514

YNT-2216

YA-1

YA-2

YA-4

BCT-0514

YNT-1614

YA-1

YA-2

YA-4

BCT-0514

0.8

(.031)

1,000

Yellow

Red

Blue

1,000

0.8

(.031)

D

4.0

(.157)

4.6

(.181)

6.8

(.268)

250

500

Note :1) The part numbers indicated in the above table are for products with a brazed seam.

When ordering products with a butted seam, add the prefix "WS" to the part number (ex. FVX2-4A –>FVXWS2-4A).

2) *The crimping will be more secure if the total cross-sectional area of the wire is at least 0.5 mm2.

Examples : If the cross-sectional area of the wire is 0.3mm2, fold the wire in two when crimping the terminal.

If the cross-sectional area of the wire is 0.5mm2, crimp the terminal onto the wire as it is.

3) Delivery lead times may vary depending on the product. Contact JST for details.

Solderless terminals

SPADE TONGUE (A type) Vinyl-insulated (funnel-entry)

BCT-0514

相關PDF資料 |

PDF描述 |

|---|---|

| 0.5-2A | 0.5 mm2, WIRE TERMINAL |

| 0.5-3A | 0.5 mm2, WIRE TERMINAL |

| 0.5-3.7X | 0.5 mm2, FORK TERMINAL |

| 0.5-5X | 0.5 mm2, FORK TERMINAL |

| 0.5-2X | 0.5 mm2, FORK TERMINAL |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| 054ABC050A-035A | 制造商:Airpax 功能描述: |

| 054EAB100A-085Y | 制造商:Airpax 功能描述: |

| 054EAB110A-095Y | 制造商:Airpax 功能描述: |

| 054EAB125A-110Y | 制造商:Airpax 功能描述: |

| 054EAB205B-180Y | 制造商:Airpax 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復。