- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄370038 > 298D476X02R5M2T (Vishay Intertechnology,Inc.) Solid Tantalum Chip Capacitors MICROTAN⑩ Lead Frameless Molded PDF資料下載

參數(shù)資料

| 型號: | 298D476X02R5M2T |

| 廠商: | Vishay Intertechnology,Inc. |

| 英文描述: | Solid Tantalum Chip Capacitors MICROTAN⑩ Lead Frameless Molded |

| 中文描述: | 固體鉭芯片電容器MICROTAN⑩鉛無框模壓 |

| 文件頁數(shù): | 4/7頁 |

| 文件大小: | 162K |

| 代理商: | 298D476X02R5M2T |

www.vishay.com

41

For technical questions, contact: tantalum@vishay.com

Document Number: 40065

Revision: 22-Oct-07

298D

Solid Tantalum Chip Capacitors

M

ICRO

T

AN

TM

Lead Frameless Molded

Vishay Sprague

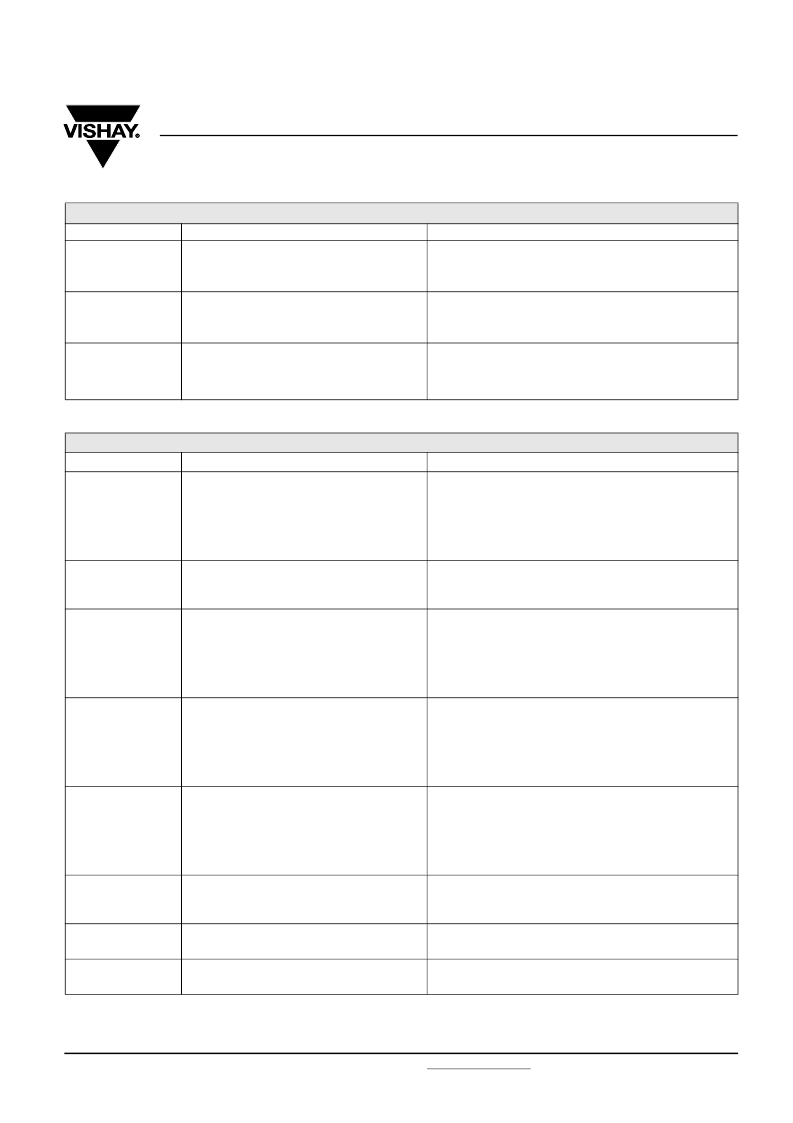

ENVIRONMENTAL PERFORMANCE CHARACTERISTICS

ITEM

CONDITION

POST TEST PERFORMANCE

Life Test at + 85 °C

1000 h application of rated voltage at

85 °C with a 3

Ω

series resistance,

MIL-STD 202G Method 108A

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

Humidity Tests

At 40 °C/90 % RH 500 h, no voltage

applied. MIL-STD 202G Method 103B

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

Thermal Shock

At - 55 °C/+ 125 °C, 30 min. each,

for 5 cycles. MIL-STD 202G Method 107G

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

MECHANICAL PERFORMANCE CHARACTERISTICS

TEST CONDITION

CONDITION

POST TEST PERFORMANCE

Terminal Strength

Apply a pressure load of 5 N for 10 ± 1 s

horizontally to the center of capacitor side body.

AECQ-200 rev. C Method 006

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Initial specified value or less

Initial specified value or less

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Substrate Bending

(Board flex)

With parts soldered onto substrate test board,

apply force to the test board for a deflection

of 1 mm. AECQ-200 rev. C Method 005

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Initial specified value or less

Initial specified value or less

Vibration

MIL-STD-202G, Method 204D,

10 Hz to 2000 Hz, 20 G Peak

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Initial specified value or less

Initial specified value or less

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Shock

Mil-Std-202G, Method 213B, Condition I,

100G Peak

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Initial specified value or less

Initial specified value or less

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Resistance to Solder

Heat

At 260 °C, for 10 seconds, reflow

Capacitance Change

Dissipation Factor

Leakage Current

Refer to Standard Ratings Table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Solderability

MIL-STD-202G, Method 208H, ANSI/J-Std-002,

Test B. Applies only to Solder and tin plated

terminations. Does not apply to gold terminations.

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Resistance to

Solvents

MIL-STD-202, Method 215D

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Flammability

Encapsulation materials meet UL94 VO with an

oxygen index of 32 %.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 298D476X06R3P2T | Solid Tantalum Chip Capacitors MICROTAN⑩ Lead Frameless Molded |

| 29F0408 | 32 Megabit (4M x 8-Bit) Flash Memory |

| 29F0408RPFB | 32 Megabit (4M x 8-Bit) Flash Memory |

| 29F0408RPFE | 32 Megabit (4M x 8-Bit) Flash Memory |

| 29F0408RPFI | 32 Megabit (4M x 8-Bit) Flash Memory |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 298D476X06R3P2T | 功能描述:鉭質(zhì)電容器-固體SMD 47uF 6.3volts 20% P case MAP RoHS:否 制造商:AVX 電容:100 uF 電壓額定值:20 V ESR: 容差:10 % 外殼代碼 - in:2917 外殼代碼 - mm:7343 高度:4.1 mm 制造商庫存號:E Case 工作溫度范圍:- 55 C to + 125 C 系列:TBM 產(chǎn)品:Tantalum Solid Low ESR Commercial Grade 封裝:Bulk |

| 298D476X06R3R2T | 制造商:Vishay Intertechnologies 功能描述:TANTALUM CAP SINGLE LAYER |

| 298D476X9004M2T | 功能描述:鉭質(zhì)電容器-固體SMD 47uF 4volts 10% M case MAP RoHS:否 制造商:AVX 電容:100 uF 電壓額定值:20 V ESR: 容差:10 % 外殼代碼 - in:2917 外殼代碼 - mm:7343 高度:4.1 mm 制造商庫存號:E Case 工作溫度范圍:- 55 C to + 125 C 系列:TBM 產(chǎn)品:Tantalum Solid Low ESR Commercial Grade 封裝:Bulk |

| 298D476X96R3P2T | 制造商:Vishay Intertechnologies 功能描述:298D Series 47 uF 10 % 6.3 V Surface Mount Solid Tantalum Chip Capacitor |

| 298DH1LP11000 | 制造商:ETRI 制造商全稱:ETRI 功能描述:DC Axial Fans |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。