- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄22673 > 4064-0-18-15-03-14-10-0 (MILL-MAX MFG CORP) BERYLLIUM COPPER ALLOY, GOLD FINISH, PCB TERMINAL PDF資料下載

參數(shù)資料

| 型號: | 4064-0-18-15-03-14-10-0 |

| 廠商: | MILL-MAX MFG CORP |

| 元件分類: | 終端 |

| 英文描述: | BERYLLIUM COPPER ALLOY, GOLD FINISH, PCB TERMINAL |

| 文件頁數(shù): | 1/1頁 |

| 文件大小: | 84K |

| 代理商: | 4064-0-18-15-03-14-10-0 |

PINS

M

A HINE

D

C

PR

EC

ISI

ON

PIN RECEPTACLES

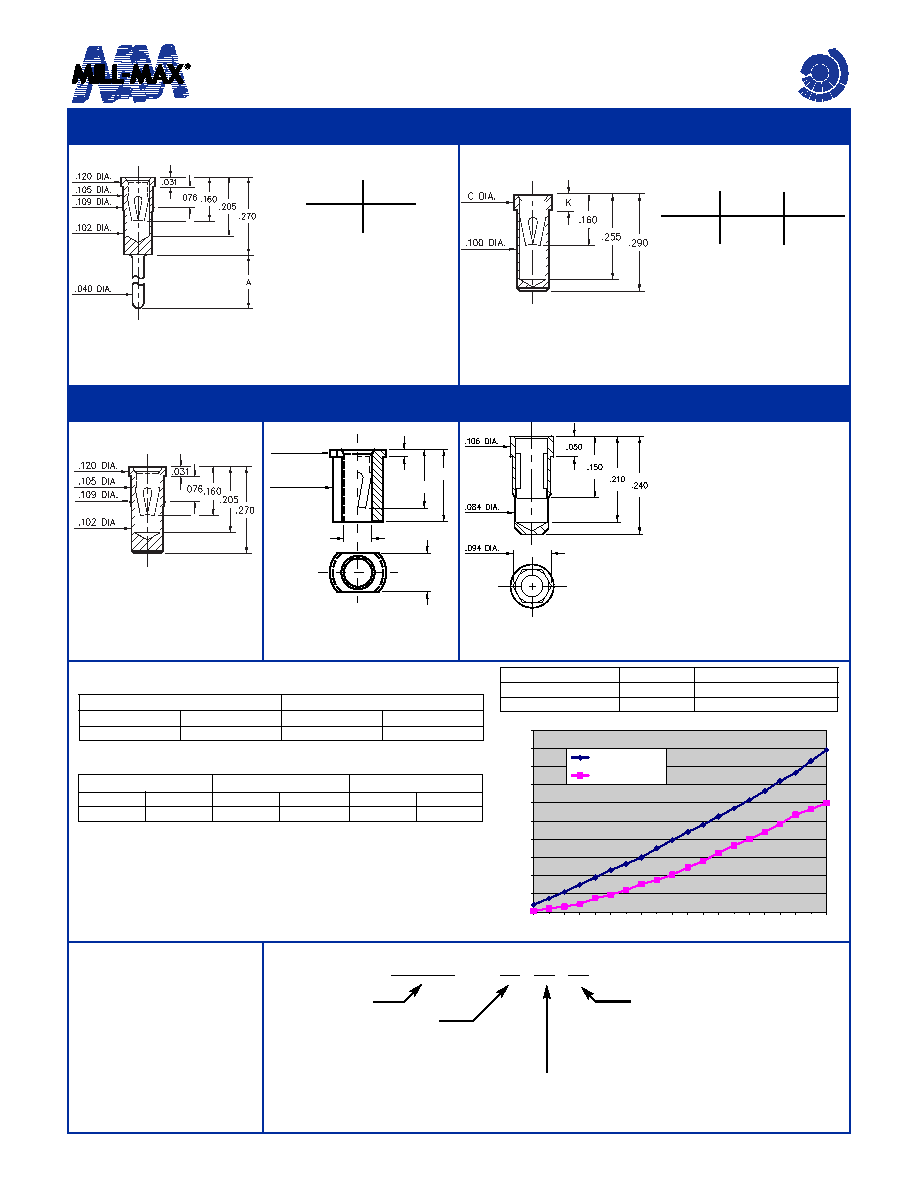

for .040” - .060” diameter pins (#03 contact)

and .059” - .063” diameter pins (#42 contact)

www.mill-max.com

516-922-6000

155

ORDER CODE: XXXX - X - 15 - XX - XX - XX -XX - 0

BASIC PART #

SPECIFY CONTACT FINISH:

SPECIFY SHELL FINISH:

01 200

" TIN/LEAD OVER NICKEL

01 200

" TIN/LEAD OVER NICKEL

14 10

" GOLD OVER NICKEL

15 10

" GOLD OVER NICKEL

27 30

" GOLD OVER NICKEL

SELECT CONTACT

#03 (DATA ON PAGE 213) or #42 CONTACT

X433-0-15-XX-03-XX-04-0

Press-fit in .106 mounting hole

0433/8433

0434-0-15-XX-03-XX-10-0

Press-fit in .106 mounting hole

0434

043X-0-15-XX-03-XX-10-0

Solder mount in .102 min.

mounting hole

0435/0436

SPECIFICATIONS

SHELL MATERIAL:

Brass Alloy 360, 1/2 Hard

CONTACT MATERIAL:

Beryllium Copper Alloy 172, HT

DIMENSION IN INCHES

TOLERANCES ON:

LENGTHS:

±.005

DIAMETERS: ±.002

ANGLES:

± 2°

Basic Part

Number

Length

A

0433-0

8433-0

.120

.330

Basic Part

Number

Dia.

C

Length

K

0435-0

0436-0

.118

.125

.050

.070

0342-0-15-XX-42-XX-10-0

Hex press-fit in .090±.002

plated thru hole

0342

4064-0-18-XX-03-XX-10-0

Surface mount

4064

0342 receptacle uses

Mill-Max’s new #42 Power

Contact. This receptacle will

accept the .061±.002

power pins of brick

DC/DC converters.

#42 contact has a very low

resistance path and is rated

for currents up to 50A.

#42 contact can be ordered

in standard receptacles that

use #03 contact; or it can be

specified as the spring

element inside custom made

receptacles for power

connector applications.

Mechanical Data #42 Contact:

Insertion/Extraction Force with a .061 (nominal) pin:

Compliancy Test (the “spring back” characteristic of the contact to accept a

.059 small pin after insertion of a .063 large pin):

(Insertion/Extraction Forces are in Newtons and measured with polished

steel gage pins having elliptical shaped tips)

Electrical/Thermal Data #42 Contact:

The electrical conductivity (resistance) of #42 contact depends on the con-

ductivity of the mating pin. Tests were made with both .060 Brass (26%

IACS) and Tellurium Copper (93% IACS) pins. Temperature rise was

measured with the receptacles mounted to simulate the heatsinking of a

multilayer circuitboard.

First Cycle

2nd & Subsequent Cycles

Insertion Force

Extraction Force

Insertion Force

Extraction Force

20N

6N

10N

6N

Initial Cycle with .059 pin

Second Cycle with .063 pin

Third Cycle with .059 pin

Ins. Force

Ext. Force

Ins. Force

Ext. Force

Ins. Force

Ext. Force

18N

6N

22N

7N

3N

2N

0

2

4

6

8

10

12

14

16

18

20

5 10 152025 303540 45505560 657075 808590 95 100

Applied Current (amps)

Temperature

Rise

(°C)

#42/Brass Pin

#42/TeCu Pin

Contact/Pin combination

Resistance

Insertion Loss per pin @ 50A

#42/ Brass

.322m

.805W

#42/TeCu

.213m

.533W

Temperature Rise vs. Applied Current

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 0191640005 | 0.96 mm2, RING TERMINAL |

| 0433750001 | BRASS, TIN (20) FINISH, WIRE TERMINAL |

| 0191640006 | 0.96 mm2, RING TERMINAL |

| 0434-0-15-80-03-27-10-0 | BERYLLIUM COPPER, GOLD (30) OVER NICKEL FINISH, PCB TERMINAL |

| 0191640007 | 0.96 mm2, RING TERMINAL |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 4064-0-18-15-03-27-400 | 制造商:Mill-Max Mfg Corp 功能描述: |

| 4064-0-18-15-03-27-40-0 | 制造商:Mill-Max Mfg Corp 功能描述:Surface Mount 0.106 Leads Range 0.04-0.06 Standard Tail Receptacle |

| 4064-0-18-15-42-27-400 | 制造商:Mill-Max Mfg Corp 功能描述: |

| 4-0640441-0 | 制造商:TE Connectivity 功能描述: |

| 406417-1 | 制造商:TE CONNECTIVITY 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。