- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄56705 > 508-AG8D-3 (THOMAS BETTS CORP) DIP24, IC SOCKET PDF資料下載

參數(shù)資料

| 型號(hào): | 508-AG8D-3 |

| 廠商: | THOMAS BETTS CORP |

| 元件分類: | 插座 |

| 英文描述: | DIP24, IC SOCKET |

| 文件頁數(shù): | 1/1頁 |

| 文件大?。?/td> | 76K |

| 代理商: | 508-AG8D-3 |

G

Thomas & Betts

1555 Lynnfield Road

Memphis, TN 38119

(901) 682-8221 FAX (901) 537-8805

G4

Quality & Innovation From The

Product Group

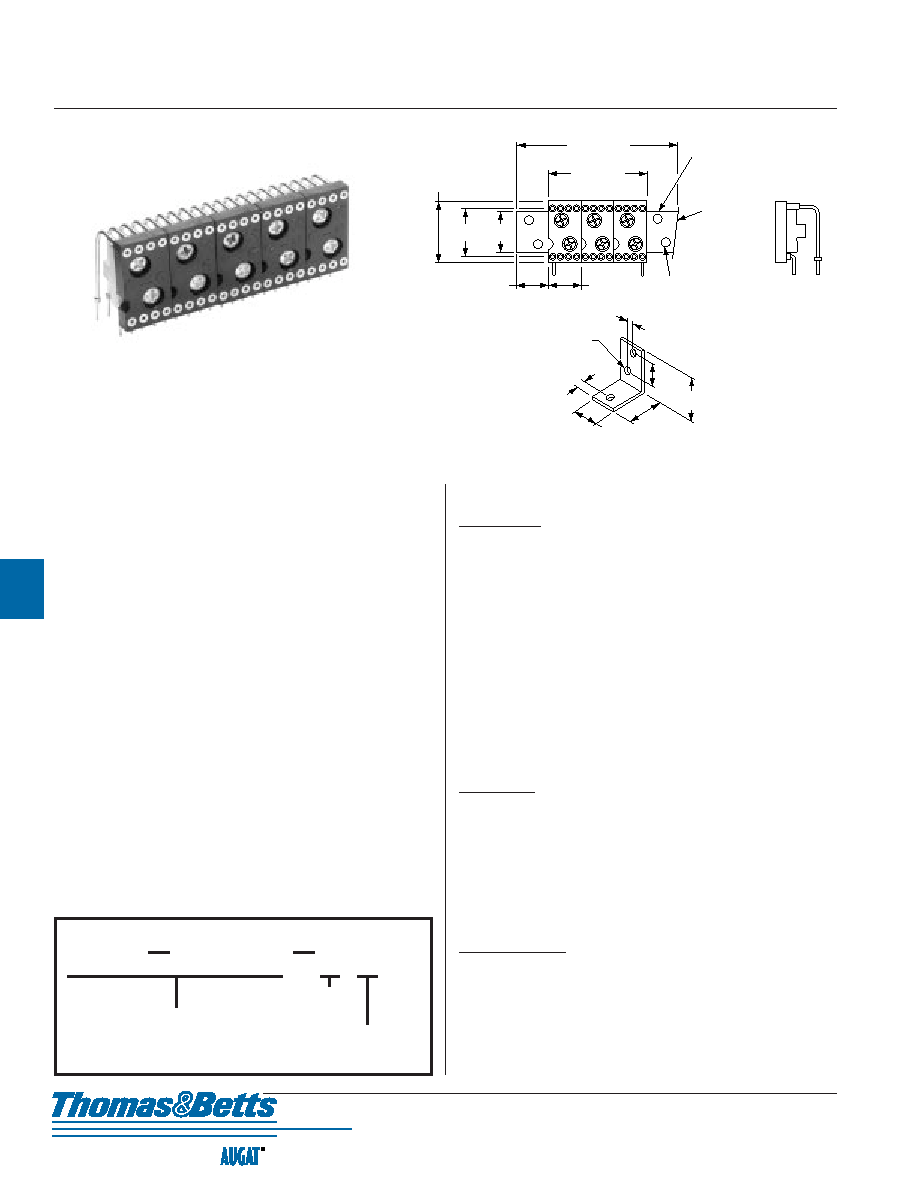

Ganged DIP Sockets

500 Series

GANGED UNIT ASSEMBLIES:

The 508 Series numbers in part block are individual sockets. Add required

dash number to appropriate socket part number for ganged unit assemblies.

With or without extrusion extension (serves as mounting ears). Units

with extrusion extensions are furnished with four No. 2 x 1/4" long self-

tapping screws.

EXTRUSION:

Extrusion for ganging also available separately, part number 508-5G1.

Simply add suffix number to indicate required length. Each extrusion is

furnished with No. 2 x 1/4" long self-tapping screws, quantity same as

number of holes in extrusion.

MOUNTING TAB:

Part number 508-4P1 is used for mounting ganged unit assemblies.

Sold separately if required.

MATERIAL SPECIFICATIONS:

Inner Contact .................. Four-fingered beryllium copper, gold

Outer Sleeve .................. Machined brass, tin/lead plated

Insulator ........................ Thermoplastic polyester UL rated 94V-0

Extrusion ........................ Vinyl

Mounting Tab ................ Stainless steel .032 (0,81) thick

3 E

5 0 8

Number

of Units

Mounting Ears

(extrusion)

Blank - No mounting ears

HOW TO ORDER

Part No. Example: 508-AG8D-3E

A G 8 D

Socket Part Number

.600

(15,24)

.500

(12,70)

.750

± .010

(19,05

± 0,25)

.400

(10,16)

Typ.

.400

(10,16)

Typ.

.076

(1,93)

Dia. Typ.

508-AG8D-3E

(with mounting ears)

508-AG8D-3

(without

mounting ears)

Extrusion

Any required

length in

multiples of

.400

(10,16)

.100

(2,54)

.093

(2,36)

Dia. Typ.

3 Places

.125

(3,18)

.270

(6,86)

.500

(12,70)

.625

(15,88)

.300

(7,62)

Mounting Tab

508-AG8D-5

PERFORMANCE SPECIFICATIONS:

MECHANICAL

Vibration ........................ Passed MIL-STD-1344, Method 2005.1,

Condition II, 10 G's

Shock .............................. Passed MIL-STD-1344, Method 2004.1,

Condition C, 100 G's

Durability ...................... Passed MIL-STD-1344, Method 2016

Normal Force ................ 200 Grams (7.0 oz.) average with .018" (0,46) dia.

polished steel pin

Insertion Force .............. 179 Grams (6.3 oz.) average with .018" (0,46) dia.

polished steel pin

Withdrawal Force .......... 63 Grams (2.2 oz.) average with .018" (0,46) dia.

polished steel pin

Solderability .................. Passed MIL-STD-202F, Method 208

Sleeve Retention

in Plastic .................... 3.0 Lbs. per line minimum PC tail

Inner Contact

Retention .................... 7.5 Lbs. per line average

ELECTRICAL

Contact Resistance ........ 10 Milliohms

Contact Rating .............. 3 Amps

Capacitance .................... 1.0 pF per MIL-STD-202, Method 305

(contact to contact)

Insulation Resistance .... 5,000 Megohms min. @ 500 VDC per

MIL-STD-1344, Method 3003.1

Dielectric Withstanding

Voltage ...................... 1,000 Volts RMS per MIL-STD-1344,

Method 3001.1

ENVIRONMENTAL

Humidity ........................ Passed MIL-STD-1344, Method 1002.2, Cond. II

Thermal Shock .............. Passed MIL-STD-1344, Method 1003.1, Cond. A

Operation Temperature .. Gold inner contact -55

°C to +125°C

Tin/lead inner contact -55

°C to +105°C

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 508-AG8D-3E | DIP24, IC SOCKET |

| 508-AG8D-5 | DIP40, IC SOCKET |

| 50AC5T15 | 3-OUTPUT 45 W AC-DC REG PWR SUPPLY MODULE |

| 50AC5D | 2-OUTPUT 45 W AC-DC REG PWR SUPPLY MODULE |

| 50AC28S | 1-OUTPUT 55 W AC-DC REG PWR SUPPLY MODULE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 508-AG8D-3E | 制造商:TE Connectivity 功能描述: |

| 50-8B/H17 | 功能描述:電容硬件 50-8B WSHR & NUT RoHS:否 制造商:Cornell Dubilier 系列: 產(chǎn)品: 封裝: |

| 508B-1 | 制造商:Newport Electronics Inc 功能描述:4-20MA LCD DISPLAY PANEL |

| 508B-2 | 制造商:Newport Electronics Inc 功能描述:LOOP POWERED METER, No. of Digits / Alpha:3-1/2, Meter Function:Current Loop Indicator, Meter Range:1mA to 5mA / 4mA to 20mA / 10mA to 50mA, Digit Height:8.9mm, Supply Voltage Range:-, Operating Temperature Min:-40C , RoHS Compliant: NA |

| 508C697G38 | 制造商:NGC 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。