- 您現在的位置:買賣IC網 > PDF目錄369340 > 7525 (Toshiba Corporation) X-ray Thickness Gage PDF資料下載

參數資料

| 型號: | 7525 |

| 廠商: | Toshiba Corporation |

| 英文描述: | X-ray Thickness Gage |

| 中文描述: | X射線測厚儀 |

| 文件頁數: | 3/14頁 |

| 文件大小: | 204K |

| 代理商: | 7525 |

No. EJD-069

3

<Main components>

Equipment cabinet

FA computer (V300)

DC power supply unit (+24V)

Circuit breaker (100V AC single phase)

Circuit breaker (200V AC single phase)

Isolated amplifier (for deviation output)

Operation-PC

Uses FA computer to display different kinds of

settings, self-diagnosis and deviation trends.

Communications are carried out via the

microcomputer and Ethernet, settings are carried

out via a microcomputer, and status detection

information is sent and received.

<Main components>

FA3100 main unit (Windows

NT)

15-type color monitor

Keyboard

Mouse

Ethernet board

Standard software package

Automatic voltage regulator

This is used to stabilize the power supply provided

to the main unit of the thickness gage. Specify

frequency of either 50 Hz or 60 Hz.

Input

200/220V AC ± 10%, 1

φ

(100/110V AC is also possible)

Output

200V AC (0.8KVA), 1

φ

100V AC (0.7KVA), 1

φ

Distortion 5% max., capacity 1.6kVA

Special Cables

Special cable between driving control box and

measuring head (20m).

Hoses

Special hose between customer's piping and

measuring head (20m).

Cooling water hose (neoprene, 3/4B)

Air purge hose (neoprene, 1/2B, 3/4B)

Nitrogen hose (neoprene, 1/4B)

Standard spare parts

Fuses

Lamps

0.5A, 3A, 5A

40W

Measuring head peripheral equipment

X-ray/shutter warning lamp

Limit switches

Documents

Contract Specifications

Contract Drawings

Test Report

Operation Manual (including maintenance)

5 copies

5 copies

5 copies

5 copies

5 copies

Schematic Diagram

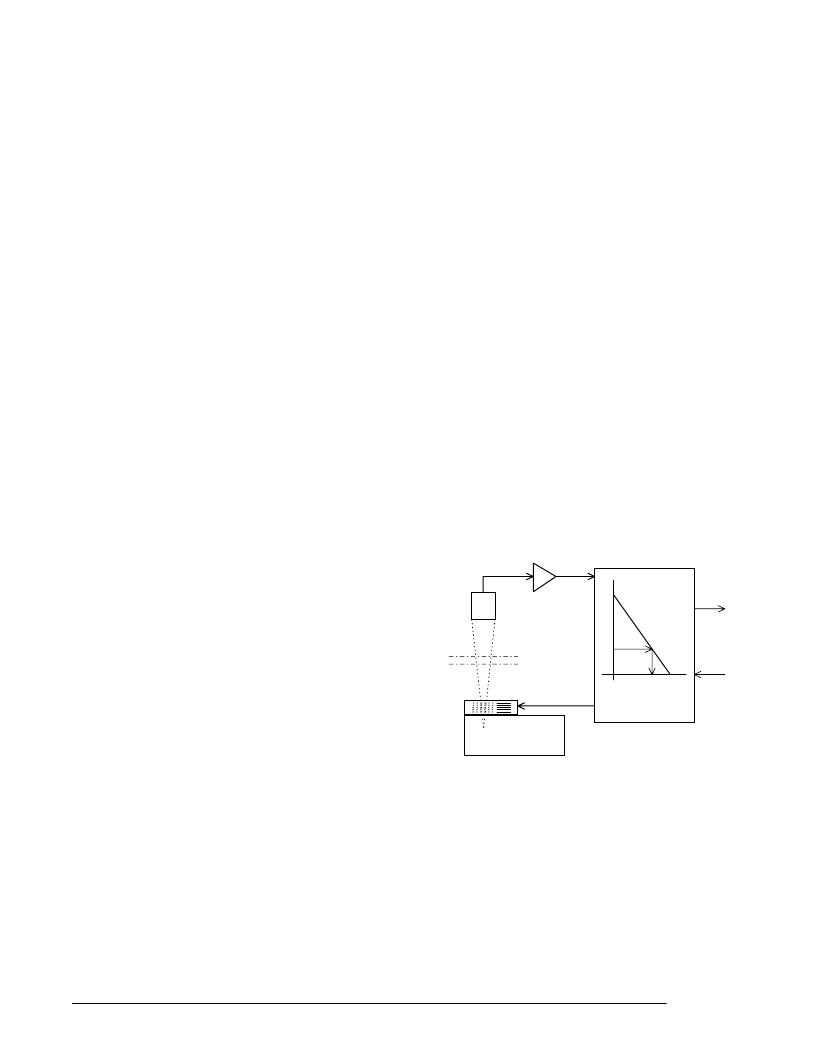

Operating Principle

When the X-rays emitted from the X-ray generator

pass through the material being measured, they are

scattered and absorbed by that material. The X-rays

that pass through the material are received by the

detector (ionization chamber) and are converted into

electrical signals (ionization current) proportional to

the quantity of X-rays. These signals are subjected to

A/D conversion at the integrated A/D converter

before being sent to the microcomputer by the high-

speed serial interface.

At the equipment cabinet, these signals are calculated

by the microcomputer and then output as thickness

signals.

Deviation

output

Setting

Integrated A/D converter

Thickness gage

Calibration

information

X-ray generator

Standard changer

Measured

material

Calibration

curve

Detector

Figure 2 Operating Principle

Measurement Method

The TOSGAGE-7525 is a single-beam thickness

gage that uses previously calibrated standard

plates to create and store a calibration curve

throughout the entire measurement range. The

signals detected for the X-rays that have passed

through the measuring material during

measurements are applied to the calibration curve

to derive the thickness.

相關PDF資料 |

PDF描述 |

|---|---|

| 7528AC | 4-Bit, Single-Chip CMOS Microcomputers With FIP Driver |

| 75323 | LINEAR INTEGRATED CIRCUIT |

| 75415-EP | POWER GOOD FAST-TRANSIENT-RESPONSE 2-A LOW-DROPOUT VOLTAGE REGULATORS |

| 75418-EP | POWER GOOD FAST-TRANSIENT-RESPONSE 2-A LOW-DROPOUT VOLTAGE REGULATORS |

| 75425-EP | POWER GOOD FAST-TRANSIENT-RESPONSE 2-A LOW-DROPOUT VOLTAGE REGULATORS |

相關代理商/技術參數 |

參數描述 |

|---|---|

| 75-250 | 制造商:THORDARSON MEISSNER 功能描述:Power Supply,Foreign,Portable,in:100/120/220/240V,50/60HZ,out:120V,250VA 制造商:Datak Corporation 功能描述:Connector Accessories Double Gang Wall Plate Cover Straight Ivory |

| 7525-001/230AC | 制造商:Redington Counters Inc 功能描述: |

| 75250201151 | 制造商:ESSEX 功能描述:25AMP RELAY COIL 240V 60HZ |

| 7525070001 | 制造商:TE Connectivity 功能描述:Heat Shrink Sleeve ST Polyolefin Yellow 制造商:TE Connectivity 功能描述:MARKER SLEEVE POLYFN YLLW - Cable Rools/Shrink Tubing |

| 752511 | 制造商: 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復。