- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄362016 > A3CA-7021 SCHALTER GRUNDELEMENT QUADRATISCH PDF資料下載

參數(shù)資料

| 型號: | A3CA-7021 |

| 英文描述: | SCHALTER GRUNDELEMENT QUADRATISCH |

| 中文描述: | SCHALTER GRUNDELEMENT QUADRATISCH |

| 文件頁數(shù): | 5/6頁 |

| 文件大小: | 203K |

| 代理商: | A3CA-7021 |

Accessories (Order Separately)

Name

Socket

Shape

Classification

Wire-wrap

terminal

Model

A3C–4101

Remarks

–

PCB terminal

A3C–4102

Solder terminal

A3C–4103

Switch guard

Rectangular

A3CJ–5050

–

T

ightening tool

–

A3C–3004

Useful for mounting switch

units one after another

. Do not

over-tighten.

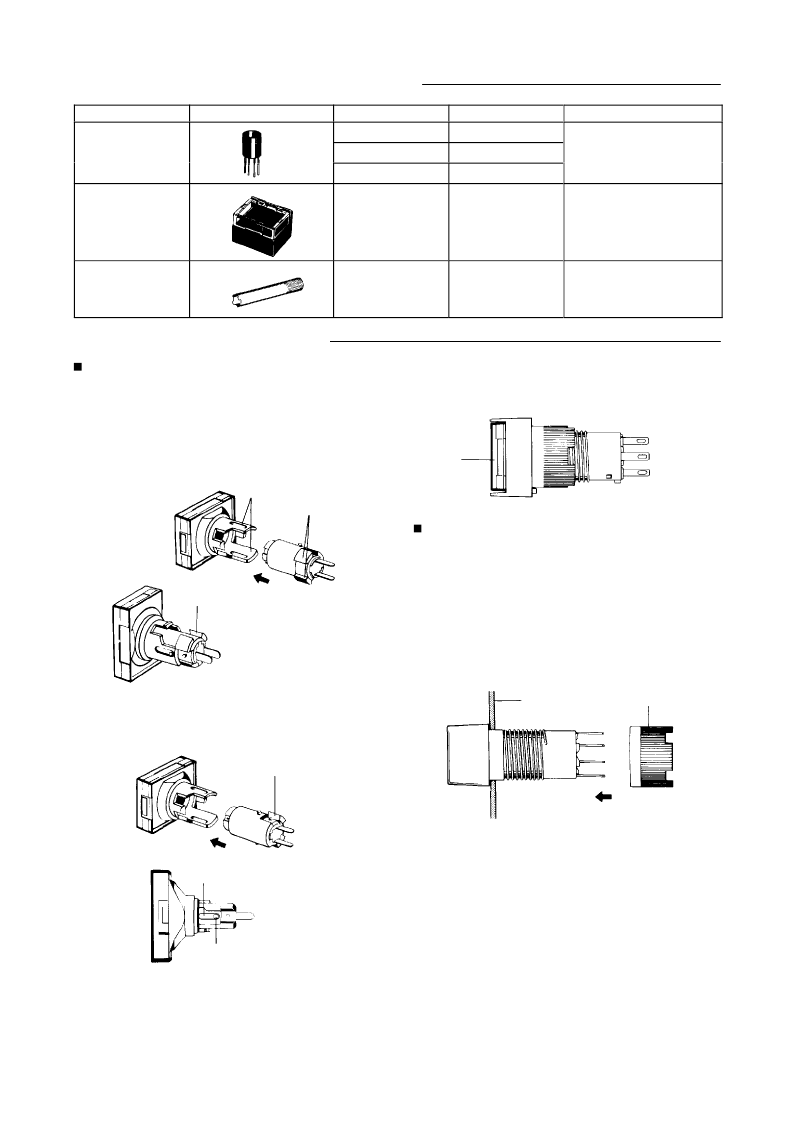

Assembly/Disassembly

Mounting and Replacing Pushbutton

Unit

Mounting directions for the LED/lamp and

Screen

The

OMRON screen doubles the roles in which a pushbutton switch

is

normally used. The screen may be inserted one of two ways:

1. For

operation as a lighted pushbutton switch, fit the LED/lamp

so that its guide projection is inserted into the

wider opening in

the

receptacle of the screen.

Projection

LED/lamp

guide

LED/lamp

guide

2.

For operation as an indicator unit, insert the LED/lamp guide

projection into the narrower opening in the indicator unit’s

receptacle.

Push the projection of the LED/lamp in the groove

of

the screen so that the LED/lamp is firmly inserted into

the

screen of the indicator unit.

LED/lamp

guide

Groove of the indicator unit

Projection of the LED/lamp

Note:

The inserting direction of the LED/lamp for the screen is

opposite to that for the indicator unit. Pay attention to the

mounting

direction of the legend plate.

Removing the pushbutton unit

While

holding the recessed portions on both sides, firmly and steadily

pull

out the top of the screen with your thumb and forefinger

. Pulling

out the cap with pliers or a similar tool will damage the cap.

Recess

Mounting the switch unit on panel

Nut mounting

Insert

the switch unit from the front of the panel and tighten the

mounting

nut inserted from the rear of the panel.

Since

a projection exists on the rear portion of the switch unit, if the

mounting

unit cannot be fitted into position, turn the nut slightly

.

The

tightening

torque of the mounting nut should be less than

5kg–cm.

Solder the terminals after mounting the nut. Otherwise, the

terminals, when thickened by solder, may prevent the nut from

being

screwed down onto the switch unit.

Wiring

Finish soldering within 5 seconds with a 30 watt soldering

iron,

or within 3 seconds at a solder temperature of

240

C.

Do not apply any force to the switch unit for about a minute

after

soldering, to avoid deforming the softened plastic base

of

the switch unit.

Use a non-corrosive, resin-based soldering flux.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| A3G-4011 | SOCKEL EINPOLIG |

| A3G-4021 | SOCKEL ZWEIPOLIG |

| A3GA-510D | LINSE OR.QUADRAT. |

| A3GA-510GN | LINSE GN.QUADRAT. |

| A3GA-6011-3 | GEHAEUSE 18X18MM |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| A3CA7111 | 制造商:OMRON AUTOMATION AND SAFETY 功能描述:SWITCH UNIT-IP40 制造商:OMRON INDUSTRIAL AUTOMATION 功能描述:SWITCH UNIT-IP40 |

| A3CA-7111 | 功能描述:開關(guān)配件 SWITCH UNIT-IP40 RoHS:否 制造商:C&K Components 類型:Cap 用于:Pushbutton Switches 設(shè)計目的: |

| A3CA7121 | 制造商:OMRON INDUSTRIAL AUTOMATION 功能描述:SWITCH UNIT-IP40 |

| A3CA-7121 | 功能描述:開關(guān)配件 SWITCH UNIT-IP40 RoHS:否 制造商:C&K Components 類型:Cap 用于:Pushbutton Switches 設(shè)計目的: |

| A3CA7121NC | 制造商:OMRON AUTOMATION AND SAFETY 功能描述:SWITCH UNIT-IP40 |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。