- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄362045 > ABA.00.250.NTL ADAPT BNC PLUG LEMO SOCKET 50 OHM PDF資料下載

參數(shù)資料

| 型號: | ABA.00.250.NTL |

| 英文描述: | ADAPT BNC PLUG LEMO SOCKET 50 OHM |

| 中文描述: | 適應(yīng)BNC插頭插座50歐姆勒莫 |

| 文件頁數(shù): | 38/39頁 |

| 文件大小: | 1317K |

| 代理商: | ABA.00.250.NTL |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁當(dāng)前第38頁第39頁

38

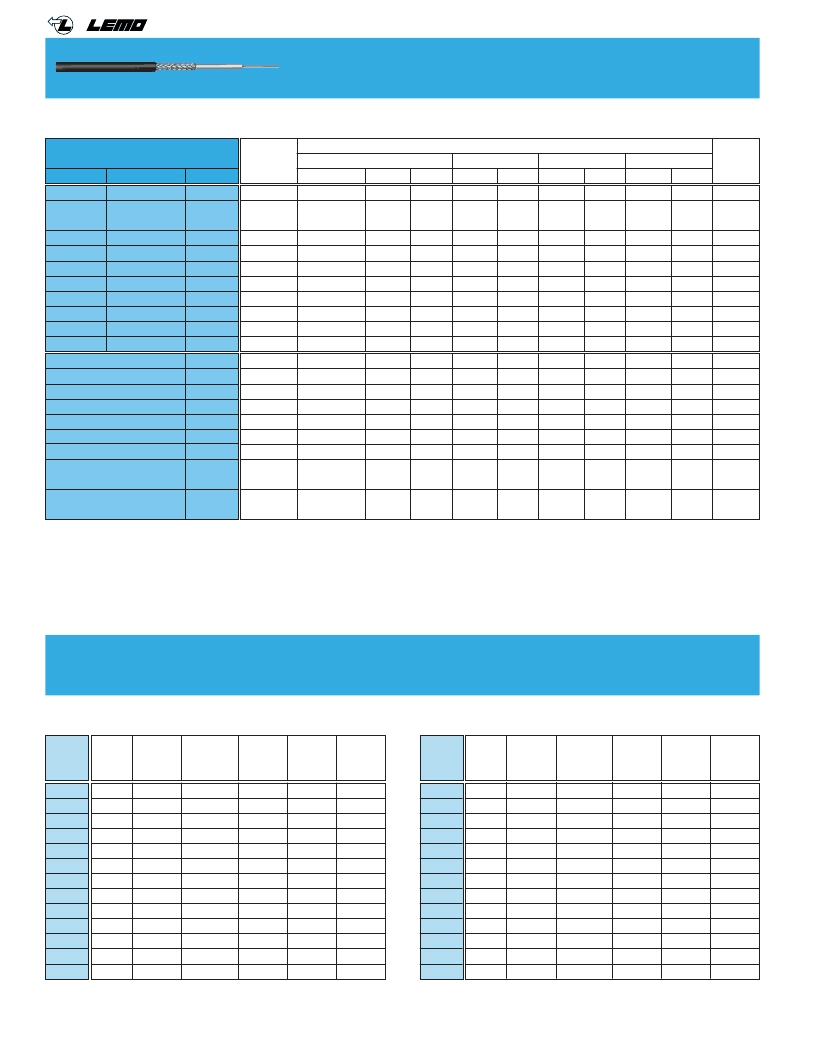

Recommended coaxial cables

50 ± 2

50 ± 2

50 ± 2

50 ± 2

50 ± 2

50 ± 2

50 ± 2

7x0.16

19x0.18

7x0.10

7x0.17

7x0.17

7x0.16

7x0.18

CuSt

CuSn

CuStAg

CuStAg

CuStAg

Cu

Cu

0.48

0.90

0.30

0.51

0.51

0.48

0.54

PE

PE

PTFE

PTFE

PTFE

PE

PE

1.52

2.95

0.86

1.52

1.52

1.32

1.50

CuSn

CuSn

CuAg

CuAg

CuAg

Cu

Cu

CuAg

CuAg

2

nd

: 2.50

-

-

-

-

-

PVC

PVC

FEP

PTFE

FEP

PVC

PoF

2.55

4.95

1.85

2.60

2.50

2.70

2.80

-

-

-

-

-

1.9

2.2

1.15

1.30

50 ± 2

7x0.16

CuStAg

0.50

PTFE

1.52

FEP

3.05

1.95

50 ± 2

7x0.16

Cu

0.50

PE

1.50

PVC

3.10

2.10

50 ± 2

19x0.18

CuSn

0.90

PE

2.95

CuSn

CuAg

CuAg

2

nd

: 4.20

3.60

PVC*

4.95

3.80

50 ± 2

50 ± 2

75 ± 3

95 ± 5

75 ± 3

50 ± 2

50 ± 2

50 ± 2

7x0.16

7x0.10

7x0.10

7x0.10

7x0.10

7x0.18

7x0.10

7x0.18

CuSt

CuStAg

CuStAg

CuStAg

CuStAg

CuStAg

CuStAg

CuStAg

0.48

0.30

0.30

0.30

0.30

0.54

0.30

0.54

PE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

1.50

0.87

1.50

2.60

1.50

1.50

0.87

1.50

CuSn

CuAg

CuAg

CuAg

CuAg

CuAg

CuAg

CuAg

2.00

1.40

2.00

3.10

2.00

2.00

1.37

2.10

PVC*

FEP

FEP

FEP

PTFE

PTFE

PTFE

FEP

2.60

1.80

2.50

3.60

2.60

2.60

2.10

2.50

1.10

0.85

1.50

3.20

1.60

1.60

1.10

1.60

RG.58C/U

KX 15

50-3-1

RG.174A/U

RG.178B/U

RG.179B/U

RG.180B/U

RG.187A/U

RG.188A/U

RG.196A/U

RG.316/U

8216

8262

83265

83269

83284

HF-2114

CCH.99.281.505 (Lemo)

1)

KX 3A

KX 21A

50-2-1

50-1-1

75-2-1

-

75-2-2

50-2-3

50-1-2

50-2-2

50-2-1

50-3-1

50-1-1

-

50-2-2

-

50-2-1

KX 22A

(Belden)

(Belden)

(Belden)

(Belden)

(Belden)

(Dtwyler)

Dimensions and characteristics

Standard / Part number (supplier)

MIL-C-17

CCTU 10-01A

CEI 96-2

421.099

(Storm)

-

G02232D-60

(H+S)

-

Construction and dimensions

Dielectric

Mat.

Conductor

Shield

Sheath

Mat.

Construction

Mat.

Mat.

Imp.

(

)

Weight

kg/100

m

1

st

: 2.00

CuAg

CuSn

2

nd

: 2.50

1

st

: 1.95

Notes:

all dimensions are in millimeters.

1)

Fire resistant according IEC 332-1.

Cu

CuAg

CuSn

CuSt

CuStAg

Bare copper

Silver-plated copper

Tinned copper

Copper-plated steel

Silvered copper plated steel

FEP

PE

PoF

PTFE

Extruded Fluorethylenpropylen

Polyethylen

Polyolefin

Wrapped or extruded

Polytetrafluorethylen

PVC

PVC*

Polyvinylchlorid

Polyvinylchlorid

(Qual.lla MIL-C-17)

0

0.1

0.2

0.3

0.3

0.4

0.5

0.6

0.7

0.7

0.8

0.9

1.0

0.000

0.000

0.000

0.001

0.003

0.003

0.004

0.005

0.006

0.008

0.010

0.012

0.014

0.00

0.00

0.01

0.01

0.03

0.02

0.03

0.03

0.04

0.04

0.05

0.05

0.06

100.0

100.0

100.0

100.0

100.0

99.9

99.9

99.9

99.9

99.8

99.8

99.7

99.7

0.0

0.0

0.0

0.0

0.0

0.1

0.1

0.1

0.1

0.2

0.2

0.3

0.3

46.1

40.1

36.6

34.2

32.3

30.7

29.4

28.3

27.3

26.4

25.7

24.9

Technical tables

VSWR effect on transmitted power

VSWR

1.00

1.01

1.02

1.03

1.04

1.05

1.06

1.07

1.08

1.09

1.10

1.11

1.12

Return

loss

(dB)

Transmiss. Reflected Transmit. Reflected

loss

voltage

(dB)

coefficient

power

(%)

power

(%)

VSWR

(dB)

1.1

1.1

1.2

1.3

1.4

1.4

1.5

1.6

1.7

1.7

1.8

1.9

1.9

24.3

23.7

23.1

22.6

22.1

21.7

21.2

20.8

20.4

20.1

19.7

19.4

19.1

0.016

0.019

0.021

0.024

0.027

0.030

0.033

0.036

0.039

0.043

0.046

0.050

0.054

0.06

0.07

0.07

0.07

0.08

0.08

0.09

0.09

0.10

0.10

0.10

0.11

0.11

99.6

99.6

99.5

99.5

99.4

99.3

99.2

99.2

99.1

99.0

98.9

98.9

98.8

0.4

0.4

0.5

0.5

0.6

0.7

0.8

0.8

0.9

1.0

1.1

1.1

1.2

VSWR

1.13

1.14

1.15

1.16

1.17

1.18

1.19

1.20

1.21

1.22

1.23

1.24

1.25

Return

loss

(dB)

Transmiss. Reflected Transmit. Reflected

loss

voltage

(dB)

coefficient

power

(%)

power

(%)

VSWR

(dB)

50 ± 2

solid

CuStAg

0.95

PTFE

2.95

FEP

4.95

6.60

RG.142B/U

-

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| ABF.00.250.CTA | ADAPT BNC SCKT LEMO PLUG 50 OHM |

| ABA-0025 | Delay Line |

| ABA-0050 | Delay Line |

| ABA-0100 | Delay Line |

| ABA-0150 | Delay Line |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| ABA-0050 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Delay Line |

| ABA-0100 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Delay Line |

| ABA010000500 | 制造商:JSP 功能描述:BUMP CAP BLUE |

| ABA-0150 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Delay Line |

| ABA-0200 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Delay Line |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。