- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄373980 > ADE7757 (Analog Devices, Inc.) Energy Metering IC with Integrated Oscillator PDF資料下載

參數(shù)資料

| 型號: | ADE7757 |

| 廠商: | Analog Devices, Inc. |

| 英文描述: | Energy Metering IC with Integrated Oscillator |

| 中文描述: | 電能計量IC集成振蕩器 |

| 文件頁數(shù): | 13/14頁 |

| 文件大小: | 534K |

| 代理商: | ADE7757 |

–13–

PRELIMINARY TECHNICAL DATA

REV. PrC.

ADE7757

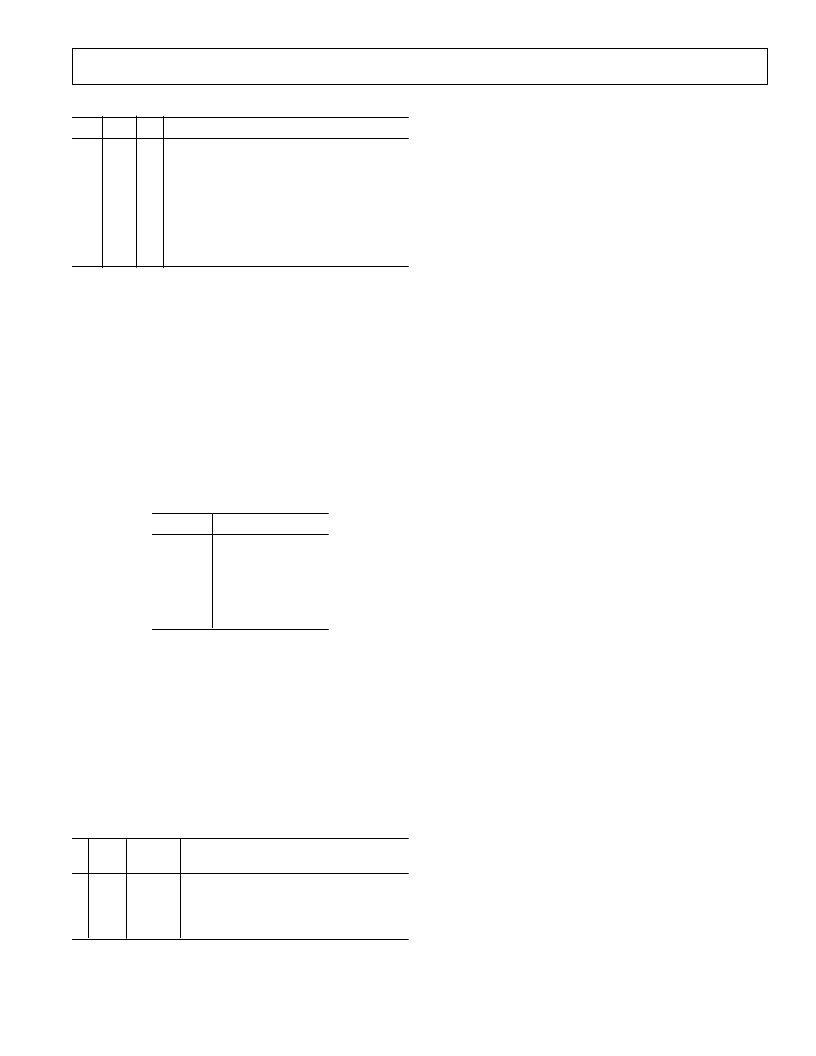

Table III. Maximum Output Frequency on CF

SCF

S1

S0

CF Max for AC Signals (Hz)

1

0

1

0

1

0

1

0

0

0

0

0

1

1

1

1

0

0

1

1

0

0

1

1

128 x F1, F2 = 22.4

64 x F1, F2 = 11.2

64 x F1, F2 = 22.4

32 x F1, F2 = 11.2

32 x F1, F2 = 22.4

16 x F1, F2 = 11.2

16 x F1, F2 = 22.4

2048 x F1, F2 = 2.867 kHz

SELECTING A FREQUENCY FOR AN ENERGY

METER APPLICATION

As shown in Table I, the user can select one of four fre-

quencies. This frequency selection determines the maxi-

mum frequency on F1 and F2. These outputs are intended

for driving an energy register (electromechanical or oth-

ers). Since only four different output frequencies can be

selected, the available frequency selection has been opti-

mized for a meter constant of 100 imp/kWhr with a maxi-

mum current of between 10 A and 120 A. Table IV shows

the output frequency for several maximum currents (I

MAX

)

with a line voltage of 220 V. In all cases the meter con-

stant is 100 imp/kWhr.

Table IV. F1 and F2 Frequency at 100 imp/kWhr

I

MAX

F1 and F2 (Hz)

12.5 A

25.0 A

40.0 A

60.0 A

80.0 A

120.0 A

0.076

0.153

0.244

0.367

0.489

0.733

The F

1

–

4

frequencies allow complete coverage of this range of

output frequencies (F1, F2). When designing an energy meter

the nominal design voltage on Channel V2 (voltage) should be

set to half-scale to allow for calibration of the meter constant.

The current channel should also be no more than half-scale

when the meter sees maximum load. This will allow over cur-

rent signals and signals with high crest factors to be accommo-

dated. Table V shows the output frequency on F1 and F2 when

both analog inputs are half-scale. The frequencies listed in

Table V align very well with those listed in Table IV for maxi-

mum load.

Table V. F1 and F2 Frequency with Half-Scale AC Inputs

Frequency on F1 and F2–

CH1 and CH2 Half-Scale AC Inputs

S1

S0

F

1–4

0

0

1

1

0

1

0

1

0.85

1.7

3.4

6.8

0.0438 Hz

0.0875 Hz

0.175 Hz

0.35 Hz

When selecting a suitable F

1

–

4

frequency for a meter de-

sign, the frequency output at I

MAX

(maximum load) with a

meter constant of 100 imp/kWhr should be compared with

Column 4 of Table V. The closest frequency in Table V

will determine the best choice of frequency (F

1

–

4

). For

example, if a meter with a maximum current of 25 A is

being designed, the output frequency on F1 and F2 with

a meter constant of 100 imp/kWhr is 0.153 Hz at 25 A and

220 V (from Table IV). Looking at Table V, the closest

frequency to 0.153 Hz in column four is 0.175 Hz. There-

fore F

3

(3.4 Hz

—

see Table I) is selected for this design.

Frequency Outputs

Figure 1 shows a timing diagram for the various frequency

outputs. The outputs F1 and F2 are the low frequency outputs

that can be used to directly drive a stepper motor or elec-

tromechanical impulse counter. The F1 and F2 outputs

provide two alternating low frequency pulses. The

pulsewidth (t

1

) is set such that if F1 and F2 falls below

1100 ms (0.909 Hz) the pulsewidth of F1 and F2 is set to

half of their period. The maximum output frequencies for

F1 and F2 are shown in Table II.

The high frequency CF output is intended to be used for

communications and calibration purposes. CF produces a

180 ms-wide active high pulse (t

4

) at a frequency propor-

tional to active power. The CF output frequencies are

given in Table III. As in the case of F1 and F2, if the

period of CF (t

5

) falls below 360 ms, the CF pulsewidth is

set to half the period. For example, if the CF frequency is

20 Hz, the CF pulsewidth is 25 ms.

NOTE: When the high frequency mode is selected, (i.e.,

SCF = 0, S1 = S0 = 1) the CF pulsewidth is fixed at

36 μs. Therefore t

4

will always be 36 μs, regardless of

output frequency on CF.

NO LOAD THRESHOLD

The ADE7757 also includes a

“

no load threshold

”

and

“

start-

up current

”

feature that will eliminate any creep effects in

the meter. The ADE7757 is designed to issue a minimum

output frequency. Any load generating a frequency lower than

this minimum frequency will not cause a pulse to be issued on

F1, F2 or CF. The minimum output frequency is given as

0.0014% of the full-scale output frequency for each of the F

1

–

4

frequency selections

—

see Table I. For example, an energy

meter with a meter constant of 100 imp/kWhr on F1, F2

using F

3

(3.4 Hz), the minimum output frequency at F1

or F2 would be 0.0014% of 3.4 Hz or 4.76 x 10

–

5

Hz.

This would be 3.05 x 10

–

3

Hz at CF (64 x F1 Hz) when

SCF = S0 = 1, S1 = 0. In this example the no load

threshold would be equivalent to 1.7 W of load or a start-

up current of 8 mA at 220 V. Comparing this value to

the IEC1036 specification which states that the meter

must start up with a load equal to or less than 0.4% Ib.

For a 5A (Ib) meter 0.4% of Ib is equivalent to 20 mA.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| ADE7757ARN | Energy Metering IC with Integrated Oscillator |

| ADE7758 | Poly Phase Multifunction Energy Metering IC with Per Phase Information |

| ADE7758ARW | Poly Phase Multifunction Energy Metering IC with Per Phase Information |

| ADE7758ARWRL | Poly Phase Multifunction Energy Metering IC with Per Phase Information |

| ADE7758ARWZ | Poly Phase Multifunction Energy Metering IC with Per Phase Information |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| ADE7757ARN | 制造商:Rochester Electronics LLC 功能描述:ENERGY METER IC W/INTEGRATED OSCILLATOR - Bulk 制造商:Analog Devices 功能描述:IC ENERGY METER |

| ADE7757ARN-REF | 制造商:Analog Devices 功能描述:REF BOARD ENERGY MTR W/INTGRATED OSCIL. - Rail/Tube |

| ADE7757ARNRL | 制造商:Analog Devices 功能描述:IC ENERGY METERING 16-SOIC TR |

| ADE7757ARNZ | 功能描述:IC ENERGY METERING 1PHASE 16SOIC RoHS:是 類別:集成電路 (IC) >> PMIC - 能量測量 系列:- 產(chǎn)品培訓(xùn)模塊:Lead (SnPb) Finish for COTS Obsolescence Mitigation Program 標(biāo)準(zhǔn)包裝:2,500 系列:* |

| ADE7757ARNZRL | 功能描述:IC ENERGY METERING 1PHASE 16SOIC RoHS:是 類別:集成電路 (IC) >> PMIC - 能量測量 系列:- 產(chǎn)品培訓(xùn)模塊:Lead (SnPb) Finish for COTS Obsolescence Mitigation Program 標(biāo)準(zhǔn)包裝:2,500 系列:* |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。