- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄362330 > AN135 Sensor Circuits and Digitally Controlled Potentiometers PDF資料下載

參數(shù)資料

| 型號: | AN135 |

| 元件分類: | 數(shù)字電位計 |

| 英文描述: | Sensor Circuits and Digitally Controlled Potentiometers |

| 中文描述: | 傳感器電路和數(shù)字控制電位器 |

| 文件頁數(shù): | 4/5頁 |

| 文件大小: | 47K |

| 代理商: | AN135 |

Xicor Application Note

AN135-4

AN135

pressure sensor that is compatible (thanks to DCP1 and

2) with full automation of the calibration process, is very

low in total power draw (< 1 milliampere, most of which

goes to transducer excitation), and (equally important) is

low in cost.

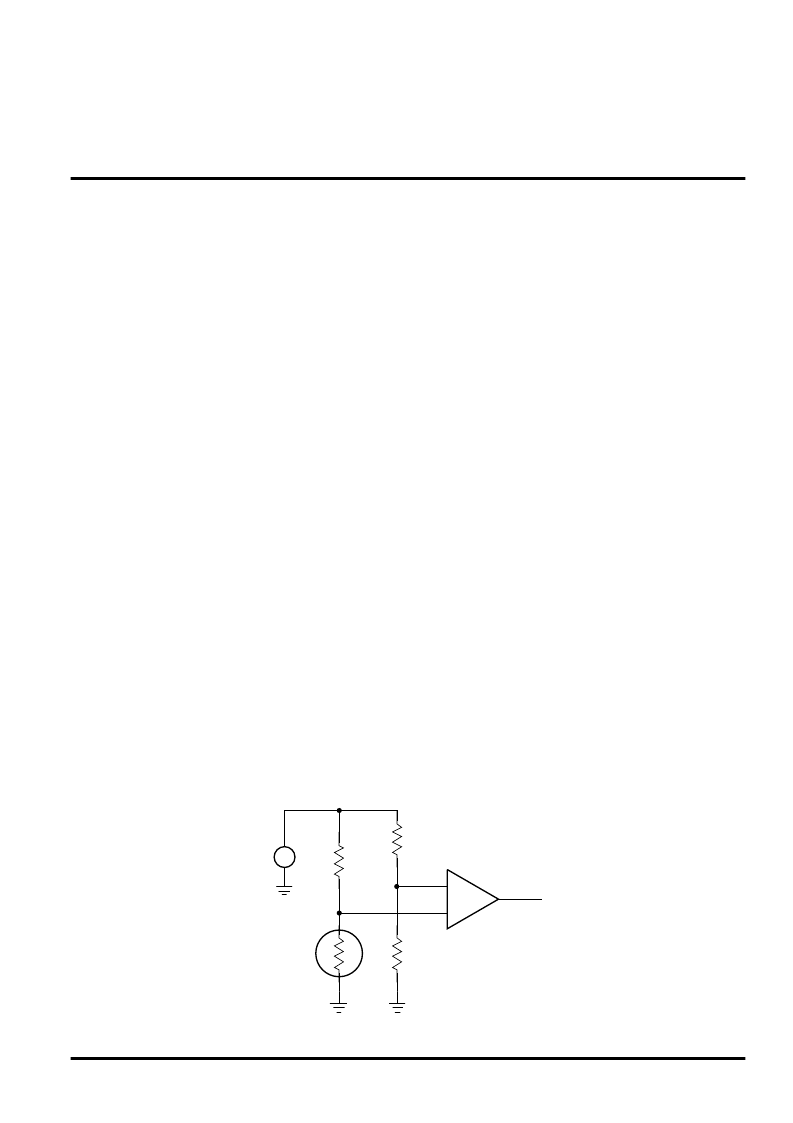

PRTD SIGNAL CONDITIONING CIRCUIT

Among

temperature

resistance temperature detector (PRTD) is generally

accepted as the ‘gold standard’. PRTDs are ubiquitous

and find wide application in the aviation, environmental,

industrial, and scientific instrumentation areas. The

circuit in Figure 5 uses the PRTD in a bridge circuit

whose output is amplified by a high performance

instrumentation amplifier (IA). Amongst the problems

associated with this traditional approach is the lack of

variablility to account for sensor variations, lack of a

linearization scheme, and the high cost of the

instrumentation amplifier.

transducers,

the

platinum

The PRTD temperature response consists of resistance

variations of the order of only tenths of ohms/°C. Hence

strict attention must be paid to the effects of transducer

lead wire resistance. The magnitude of the excitation

current must also be severely limited, otherwise

excessive I

R PRTD power dissipation will cause

unacceptably large self-heating measurement errors.

Low excitation currents and small resistance changes

combine to mean that the signal developed by the PRTD

will typically be of the order of tens of μV/°C generating

a requirement for stable high gain DC amplification in

the signal chain. In addition, the PRTD temperature

coefficient

is

only

‘reasonably’

temperature and, as a result, the PRTD’s response is

significantly nonlinear. The accurate measurement of

temperature over a wide range depends on the

provision for linearization of the PRTD signal. These

design considerations are incorporated in the circuit of

Figure 6 and result in a precision thermometer with

2

invariant

with

output span of –1V to +3.5V corresponding to a

temperature range of –100 to +350°C. The maximum

error over this span can be adjusted to ±0.02°C at 0°C

and ±0.05°C elsewhere.

Current excitation (approximately 250μA) for the PRTD

is sourced by the 2.5V voltage reference VR1 via R1.

The 256 tap digitally controlled potentiometer DCP1

provides for automated adjustment of the thermometer

scale factor and span. A1 is a noninverting amplifier with

a gain of 100 which scales up the raw 100μV/°C PRTD

temperature signal to 0.01V/°C. The DCP2 network

implements a high resolution zero adjustment. Each

increment in DCP2’s setting will result in a 200μV shift in

Al’s output which is equivalent to a 0.02°C zero

adjustment. The symmetry of the R6-R9 network

surrounding DCP2 causes zero adjustment to have no

effect on A1’s gain and therefore no effect on the

thermometer’s span/scale factor. Likewise, span

adjustments via changes in the VR1 reference allow no

interaction between DCP1 and the zero calibration

established by DCP2.

Positive feedback provided by R2 linearizes the

thermometer’s response curve by providing a Thevenin

equivalent of a negative amplifier input resistance of –

2064 ohms in parallel with R1. This introduces a positive

gain slope (roughly +0.016%/°C) which effectively

cancels the tendency of the PRTD temperature

coefficient to decline with increasing temperature. The

result is better than a factor of 100 improvement in

linearity over the raw PRTD response.

The net result of the combination of A1 and the

associated circuit is a signal conditioning, precision

temperature sensor that is compatible (thanks to DCP1

and 2) with full automation of the calibration process,

low in total power draw, and low in cost.

Figure 5. PRTD Sensor Circuit – Basic

V

BIAS

V

OUT

∝

°CV

PRTD

IA

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| AN2012S | Optoelectronic |

| AN2012SB | Optoelectronic |

| AN201 | JT 22C 22#22D PIN RECP |

| AN2034FAP | Video Camera Circuit |

| AN2035FAQ | Optoelectronic |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| AN1354 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:SINGLE-PHASE INDUCTION MOTOR DRIVE FOR REFRIGERATOR COMPRESSOR APPLICATION |

| AN1358 | 制造商:PANASONIC 制造商全稱:Panasonic Semiconductor 功能描述:Dual Operational Amplifiers |

| AN1358S | 制造商:Panasonic Industrial Company 功能描述:IC |

| AN1358S(AN6562S) | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Voltage-Feedback Operational Amplifier |

| AN1358S-E1 | 制造商:Panasonic Industrial Company 功能描述:IC |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。