- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄166228 > AQ1057N5J-T (TAIYO YUDEN CO LTD) 1 ELEMENT, 0.0075 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR, SMD PDF資料下載

參數(shù)資料

| 型號(hào): | AQ1057N5J-T |

| 廠商: | TAIYO YUDEN CO LTD |

| 元件分類: | 通用定值電感 |

| 英文描述: | 1 ELEMENT, 0.0075 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| 封裝: | CHIP, 0402, ROHS COMPLIANT |

| 文件頁(yè)數(shù): | 8/18頁(yè) |

| 文件大小: | 804K |

| 代理商: | AQ1057N5J-T |

第1頁(yè)第2頁(yè)第3頁(yè)第4頁(yè)第5頁(yè)第6頁(yè)第7頁(yè)當(dāng)前第8頁(yè)第9頁(yè)第10頁(yè)第11頁(yè)第12頁(yè)第13頁(yè)第14頁(yè)第15頁(yè)第16頁(yè)第17頁(yè)第18頁(yè)

262

Please read the "Notice for TAIYO YUDEN products" before using this catalog.

5/7

4.

1/2 1/3

100 130

20W

1

5.

1.

260

10

260

10

150

60

350

3

120

60

150

230

40

100

190

3216

130

3225

20W

1

300

200

100

0

300

200

100

0

400

300

200

100

0

Peak 260

max

10 sec max

Pb free soldering

Peak 260

max

10 sec max

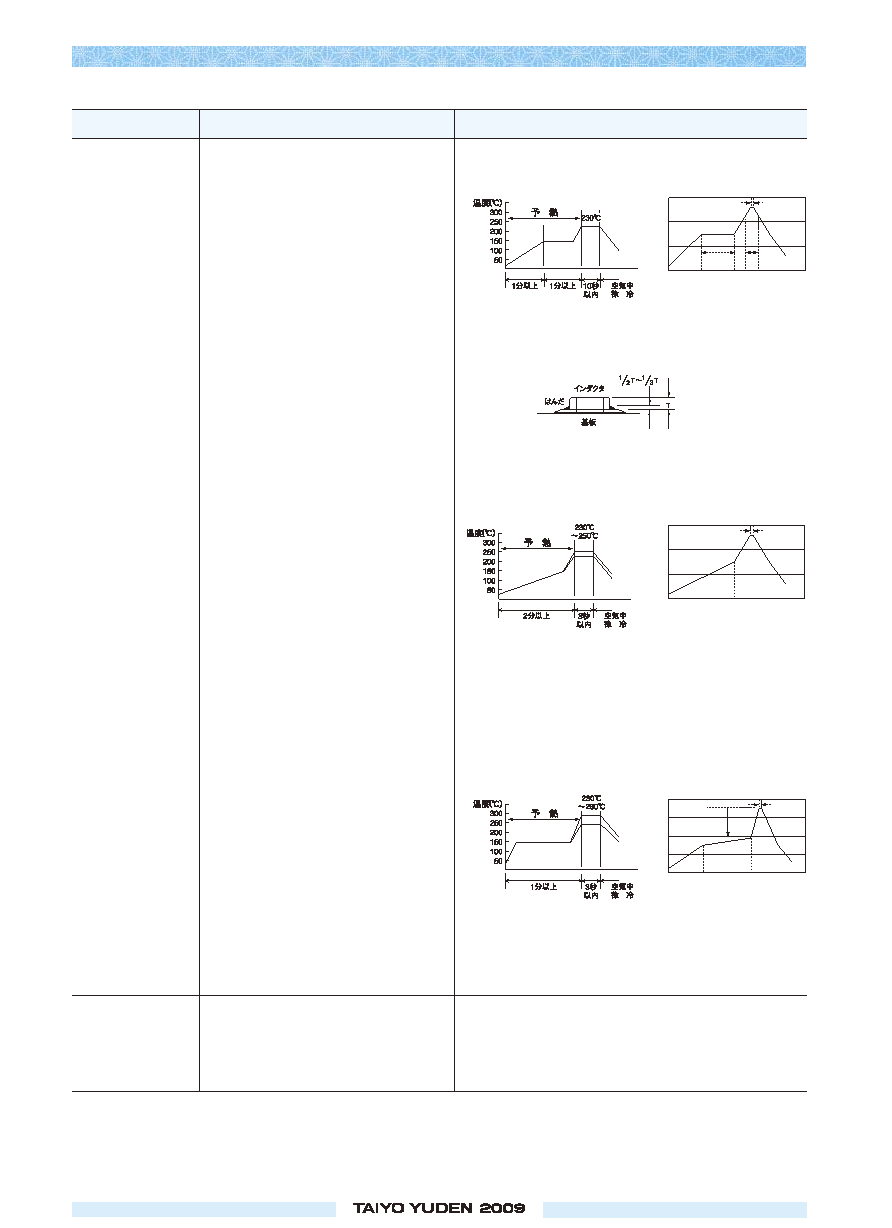

Ceramic chip components should be preheated to

within 100 to 130

of the soldering.

Assured to be reflow soldering for 2 times.

Ceramic chip components should be preheated to

within 100 to 130

of the soldering.

Assured to be wave soldering for 1 time.

Except for reflow soldering type.

T190

3216Type max ,

130

3225

Type ming

It is recommended to use 20W soldering iron and

the tip is 1 or less.

The soldering iron should not directly touch the

components.

Assured to be soldering iron for 1 time.

Note: The above profiles are the maximum allowable

soldering condition, therefore these profiles are

not always recommended.

Temperature

300

200

100

0

Temperature

300

200

100

0

Temperature

400

300

200

100

0

Preheating

150

60 sec min

Gradually

cooling

Gradually

cooling

Gradually

cooling

Heating above 230

40 sec max

Preheating

150

120 sec min

350

max

3 sec max

60 sec min

260

10

260

10

150

60

350

3

120

60

150

230

40

100

190

3216

130

3225

20W

1

300

200

100

0

300

200

100

0

400

300

200

100

0

Peak 260

max

10 sec max

Pb free soldering

Peak 260

max

10 sec max

Ceramic chip components should be preheated to

within 100 to 130

of the soldering.

Assured to be reflow soldering for 2 times.

Ceramic chip components should be preheated to

within 100 to 130

of the soldering.

Assured to be wave soldering for 1 time.

Except for reflow soldering type.

T190

3216Type max ,

130

3225

Type ming

It is recommended to use 20W soldering iron and

the tip is 1 or less.

The soldering iron should not directly touch the

components.

Assured to be soldering iron for 1 time.

Note: The above profiles are the maximum allowable

soldering condition, therefore these profiles are

not always recommended.

Temperature

300

200

100

0

Temperature

300

200

100

0

Temperature

400

300

200

100

0

Preheating

150

60 sec min

Gradually

cooling

Gradually

cooling

Gradually

cooling

Heating above 230

40 sec max

Preheating

150

120 sec min

350

max

3 sec max

60 sec min

260

10

260

10

150

60

350

3

120

60

150

230

40

100

190

3216

130

3225

20W

1

300

200

100

0

300

200

100

0

400

300

200

100

0

Peak 260

max

10 sec max

Pb free soldering

Peak 260

max

10 sec max

Ceramic chip components should be preheated to

within 100 to 130

of the soldering.

Assured to be reflow soldering for 2 times.

Ceramic chip components should be preheated to

within 100 to 130

of the soldering.

Assured to be wave soldering for 1 time.

Except for reflow soldering type.

T190

3216Type max ,

130

3225

Type ming

It is recommended to use 20W soldering iron and

the tip is 1 or less.

The soldering iron should not directly touch the

components.

Assured to be soldering iron for 1 time.

Note: The above profiles are the maximum allowable

soldering condition, therefore these profiles are

not always recommended.

Temperature

300

200

100

0

Temperature

300

200

100

0

Temperature

400

300

200

100

0

Preheating

150

60 sec min

Gradually

cooling

Gradually

cooling

Gradually

cooling

Heating above 230

40 sec max

Preheating

150

120 sec min

350

max

3 sec max

60 sec min

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| AQ1054N3S-T | 1 ELEMENT, 0.0043 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| AQ1053N6S-T | 1 ELEMENT, 0.0036 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| AQ1052N4S-T | 1 ELEMENT, 0.0024 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| AQGP322 | GENERAL PURPOSE AUDIO CONNECTOR, PLUG |

| QGP323 | |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| AQ1058N2J-T | 功能描述:固定電感器 INDCTR HIFREQ MLTLYR 0402 8.2nH 5% RoHS:否 制造商:AVX 電感:10 uH 容差:20 % 最大直流電流:1 A 最大直流電阻:0.075 Ohms 工作溫度范圍:- 40 C to + 85 C 自諧振頻率:38 MHz Q 最小值:40 尺寸:4.45 mm W x 6.6 mm L x 2.92 mm H 屏蔽:Shielded 端接類型:SMD/SMT 封裝 / 箱體:6.6 mm x 4.45 mm |

| AQ1059N1J-T | 功能描述:固定電感器 INDCTR HIFREQ MLTLYR 0402 9.1nH 5% RoHS:否 制造商:AVX 電感:10 uH 容差:20 % 最大直流電流:1 A 最大直流電阻:0.075 Ohms 工作溫度范圍:- 40 C to + 85 C 自諧振頻率:38 MHz Q 最小值:40 尺寸:4.45 mm W x 6.6 mm L x 2.92 mm H 屏蔽:Shielded 端接類型:SMD/SMT 封裝 / 箱體:6.6 mm x 4.45 mm |

| AQ105DY-C5-12-TR | 制造商:ACUTECH 制造商全稱:ACUTECH 功能描述:Secondary V/I amplifier SOT23-5 and SC70-5 Package |

| AQ105DY-C5-12-TRL | 制造商:ACUTECH 制造商全稱:ACUTECH 功能描述:Secondary V/I amplifier SOT23-5 and SC70-5 Package |

| AQ105DY-M5-12-TR | 制造商:ACUTECH 制造商全稱:ACUTECH 功能描述:Secondary V/I amplifier SOT23-5 and SC70-5 Package |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。