- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄166386 > AZD1009F SNAP ACTING/LIMIT SWITCH, SPST, MOMENTARY, 5A, 24VDC, 9mm, PANEL MOUNT PDF資料下載

參數(shù)資料

| 型號: | AZD1009F |

| 元件分類: | 開關 |

| 英文描述: | SNAP ACTING/LIMIT SWITCH, SPST, MOMENTARY, 5A, 24VDC, 9mm, PANEL MOUNT |

| 封裝: | CADMIUM FREE |

| 文件頁數(shù): | 21/23頁 |

| 文件大?。?/td> | 698K |

| 代理商: | AZD1009F |

49

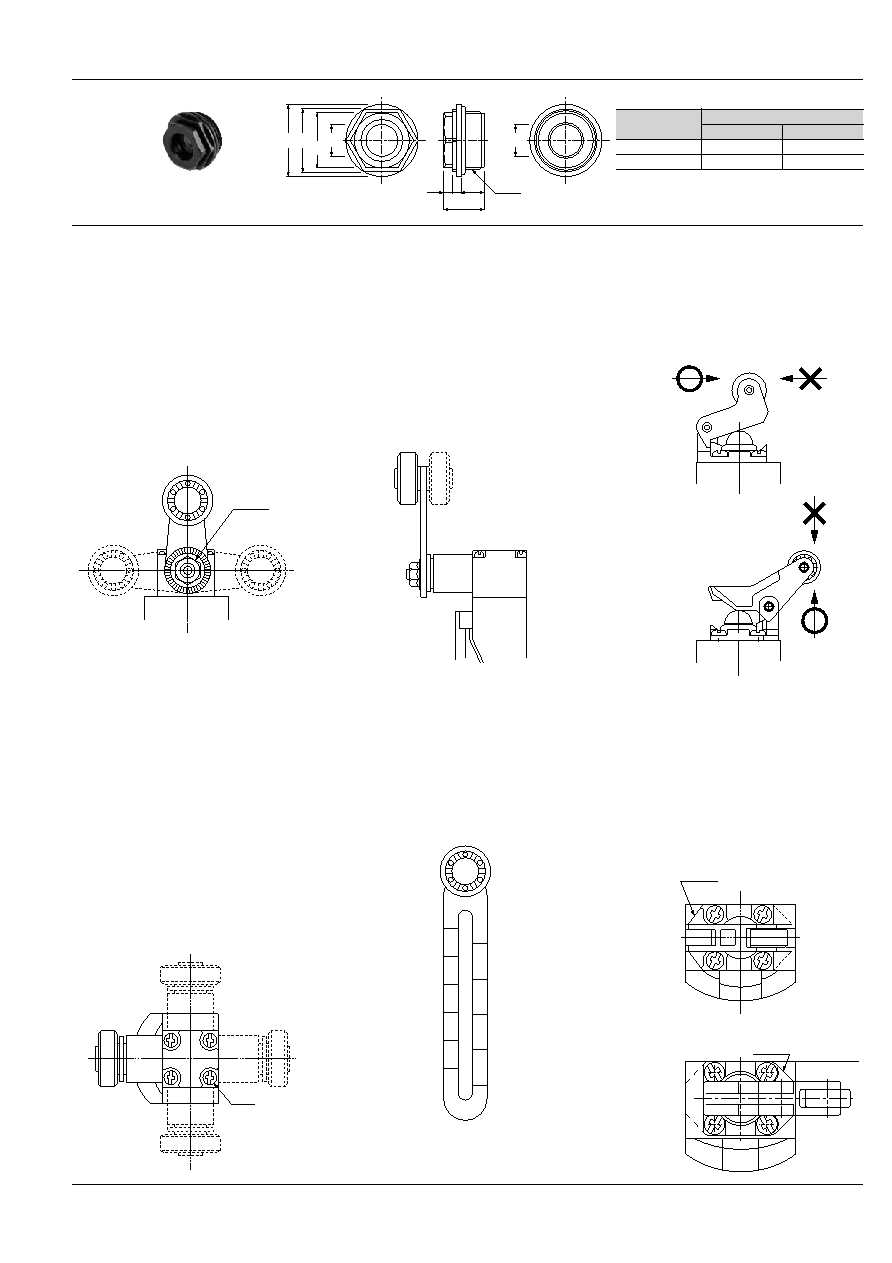

Arm Setting Position

The roller arm of the arm types

(AZD1003, AZD1004, AZD1008,

AZD1053, AZD1054 and AZD1058) can

be set in any position at 15° intervals.

Loosen the arm fastening hex. nut, repo-

sition the arm, and retighten the hex. nut.

When doing so tighten the hex. nut with

the arm secured to the unit. Tightening

without securing may cause damage.

Also, the same is true of the adjustable

rod types (AZD1007 and AZD1057).

Roller Direction

The roller of the arm types (AZD1003,

AZD1004, AZD1008, AZD1053,

AZD1054 and AZD1058) can be mount-

ed on the front and rear (dotted line in

the figure) sides of the switch, as shown

below. (Positioned on the front side at

delivery.)

To set the roller on the rear side, remove

the arm fastening hex. nut, and reinsert

the arm so as to face the roller in the

rear direction. Then, retighten the hex.

nut.

Roller Lever Direction

AZD1000, AZD1009, AZD1050 and

AZD1059 type is move a detection object

in the D direction as shown below. Be

sure not to move the object oppositely.

If the opposite direction is required,

change the direction of the lever.

Hex. nut

Adjustable Arm Length

To adjust the length of the adjustable

arm of AZD1003, AZD1008, AZD1053

and AZD1058, slightly loosen the arm

fastening hex. nut, and adjust the length.

The adjustable arm is graduated in two

kinds of length units. Use these indica-

tions as the reference during adjustment.

20

40

60

3

2

1

D

The roller lever can be set in two direc-

tions at 180° intervals. (Even though it

can be also set in the 90° direction, the

mounting surface will project.) Remove

the four lever base fastening screws,

turn the lever together with the lever

base in 180°, and retighten the four

screws at a torque of 0.20 to 0.39 Nm {2

to 4 kgcm}.

Mounting surface

Lever base

Mounting

surface

Lever base

Head Block Direction

The head of the arm types (AZD1003,

AZD1004, AZD1008, AZD1053,

AZD1054 and AZD1058) can be set in

any of four directions at 90° intervals, but

not in any other intermediate directions.

Loosen four screws on the upper side of

the head, and set the head in a desired

direction, and retighten them at a torque

of 0.20 to 0.39 Nm {2 to 4 kgcm}. Be

careful not to use too much strength

when tightening as this will cause the

threads to strip. Also, the same is true of

the adjustable rod types (AZD1007 and

AZD1057).

Screw

DL (AZD1)

Conduit connector

AZD1830

General tolerance: ±0.5 ±.020

11 dia.

25 dia. 22

19

(14)

33

G.1/2

8

11 dia.

(.551)

.118

.118 .315

.433

.984

.748

.866

Rubber seal

inside diameter

9 dia. (.354)

Adaptable cable outer diameter

Min.

Max.

7.5 dia. (.295)

9.5 dia. (.374)

11 dia. (.433)

9 dia. (.354)

11 dia. (.433)

mm inch

相關PDF資料 |

PDF描述 |

|---|---|

| AZD1002 | SNAP ACTING/LIMIT SWITCH, SPST, MOMENTARY, 5A, 24VDC, 6mm, PANEL MOUNT |

| AZD1053F | SNAP ACTING/LIMIT SWITCH, SPST, MOMENTARY, 5A, 24VDC, PANEL MOUNT |

| AZH1224 | SNAP ACTING/LIMIT SWITCH, SPDT, MOMENTARY, 11mm, PANEL MOUNT |

| AZH1002 | SNAP ACTING/LIMIT SWITCH, SPDT, MOMENTARY, 5A, 30VDC, 4.5mm, PANEL MOUNT |

| AZH1011 | SNAP ACTING/LIMIT SWITCH, SPDT, MOMENTARY, 5A, 30VDC, 4.5mm, PANEL MOUNT |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| AZD1050 | 制造商:Panasonic Electric Works 功能描述: |

| AZD1050CEJ | 制造商:Panasonic Electric Works 功能描述:Limit switch one-way roll positive open |

| AZD1051CEJ | 制造商:Panasonic Electric Works 功能描述:limit switch, push plunger |

| AZD1052 | 制造商:Panasonic Electric Works 功能描述:Switch Limit N.O./N.C. SPDT Top Roller Plunger Conduit 6A 380VAC 220VDC 6.37N Linear Screw Mount |

| AZD1052CEJ | 制造商:Panasonic Electric Works 功能描述:limit switch, roller plunger |

發(fā)布緊急采購,3分鐘左右您將得到回復。