- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄298987 > DDW1046 DC-DC REG PWR SUPPLY MODULE PDF資料下載

參數(shù)資料

| 型號: | DDW1046 |

| 元件分類: | 電源模塊 |

| 英文描述: | DC-DC REG PWR SUPPLY MODULE |

| 封裝: | PLASTIC, DIP-6/16 |

| 文件頁數(shù): | 4/8頁 |

| 文件大?。?/td> | 274K |

| 代理商: | DDW1046 |

4

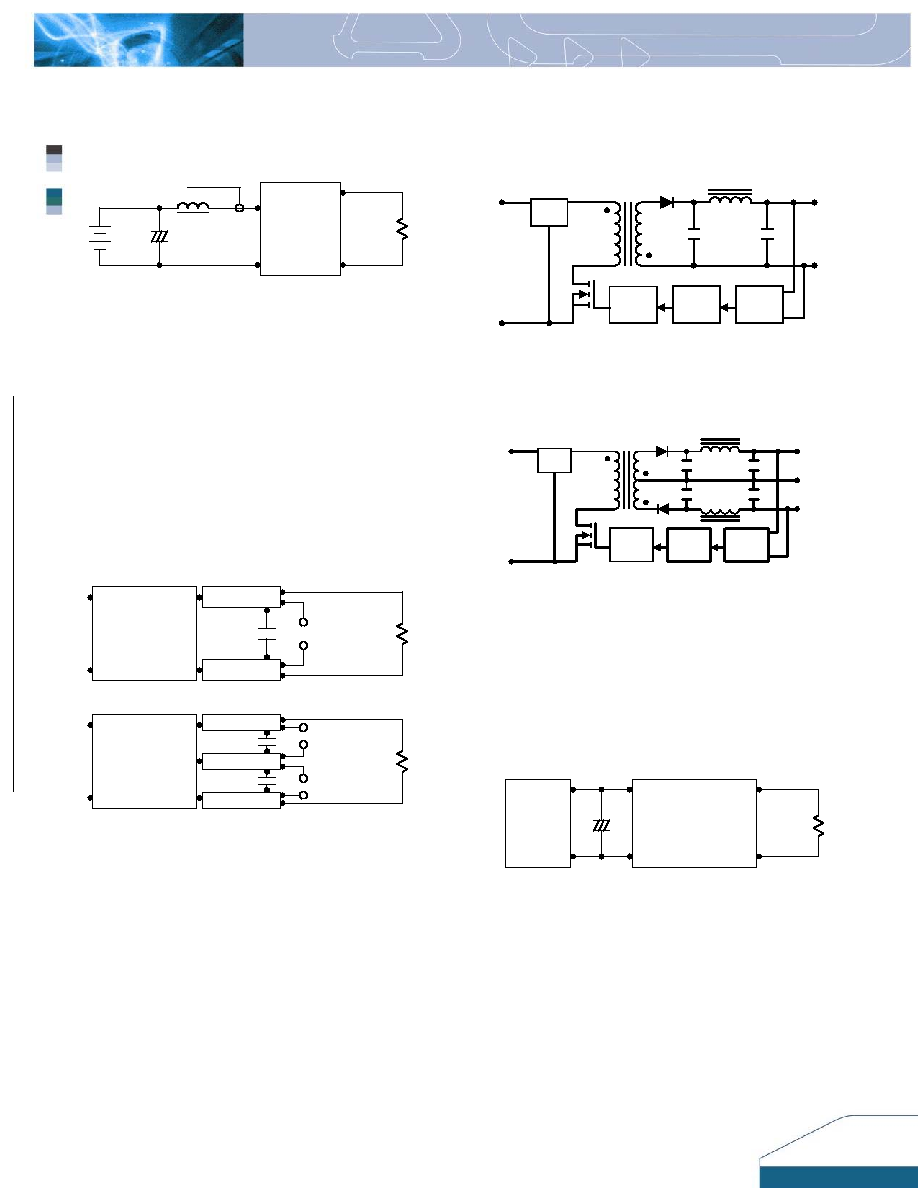

Test Configurations

Input Reflected-Ripple Current Test

Setup

+Out

-Out

+Vin

-Vin

DC / DC

Converter

Load

Battery

+

Lin

+

Cin

To Oscilloscope

Current

Probe

Input reflected-ripple current is measured with a

inductor Lin (4.7uH) and Cin (220uF, ESR < 1.0 at

100 KHz) to simulate source impedance. Capacitor

Cin is to offset possible battery impedance. Current

ripple is measured at the input terminals of the

module and measurement bandwidth is 0-500 KHz.

Peak-to-Peak Output Noise Measurement

Scope measurement should be made by using a

BNC socket, measurement bandwidth is 0-20 MHz.

Position the load between 50 mm and 75 mm from

the DC/DC Converter. A Cout of 0.47uF ceramic

capacitor is placed between the terminals shown

below.

+Out

-Out

+Vin

-Vin

Single Output

DC / DC

Converter

Resistive

Load

Scope

Copper Strip

Cout

+Out

-Out

+Vin

-Vin

Dual Output

DC / DC

Converter

Resistive

Load

Scope

Copper Strip

Cout

Com.

Scope

Cout

Design & Feature Considerations

The DDW1000 circuit block diagrams are shown in

Figures 5 and 6.

PFM

Isolation

Ref.Amp

LC

Filter

+Vin

-Vin

-Vo

+Vo

Figure 5: Block diagram of DDW1000 single output

modules.

+Vo

PFM

Isolation

Ref.Amp

LC

Filter

+Vin

-Vin

Com

-Vo

Figure 6: Block diagram of DDW1000 dual output

modules.

Input Source Impedance

The power module should be connected to a low ac-

impedance input source. Highly inductive source

impedances can affect the stability of the power

module.

+

+Out

-Out

+Vin

-Vin

DC / DC

Converter

Load

DC Power

Source

+

-

Cin

In applications where power is supplied over long lines

and output loading is high, it may be necessary to use

a capacitor at the input to ensure startup.

Capacitor mounted close to the input of the power

module helps ensure stability of the unit, it is

recommended to use a good quality low Equivalent

Series Resistance (ESR < 1.0 at 100 KHz) capacitor

of a 8.2uF for the 5V input devices, a 3.3uF for the

12V input devices, and a 1.5uF for the 24V and 48V

devices.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| DDW1021 | DC-DC REG PWR SUPPLY MODULE |

| DDW1024 | DC-DC REG PWR SUPPLY MODULE |

| DDW1043 | DC-DC REG PWR SUPPLY MODULE |

| DDW1045 | DC-DC REG PWR SUPPLY MODULE |

| DDW1036 | DC-DC REG PWR SUPPLY MODULE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| DDW-CJD-R1 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-R2 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-RS2-1 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-S1 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-S2 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。