- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄362651 > EL7562CUZ (INTERSIL CORP) Monolithic 2Amp DC-DC Step-Down Regulator PDF資料下載

參數(shù)資料

| 型號(hào): | EL7562CUZ |

| 廠商: | INTERSIL CORP |

| 元件分類: | 穩(wěn)壓器 |

| 英文描述: | Monolithic 2Amp DC-DC Step-Down Regulator |

| 中文描述: | 3 A SWITCHING REGULATOR, 1000 kHz SWITCHING FREQ-MAX, PDSO16 |

| 封裝: | ROHS COMPLIANT, QSOP-16 |

| 文件頁(yè)數(shù): | 8/9頁(yè) |

| 文件大?。?/td> | 169K |

| 代理商: | EL7562CUZ |

8

The heart of the controller is an input direct summing

comparator which sum voltage feedback, current feedback,

slope compensation ramp and power tracking signals

together. Slope compensation is required to prevent system

instability that occurs in current-mode topologies operating

at duty-cycles greater than 50% and is also used to define

the open-loop gain of the overall system. The slope

compensation is fixed internally and optimized for 500mA

inductor ripple current. The power tracking will not contribute

any input to the comparator steady-state operation. Current

feedback is measured by the patented sensing scheme that

senses the inductor current flowing through the high-side

switch whenever it is conducting. At the beginning of each

oscillator period the high-side NMOS switch is turned on.

The comparator inputs are gated off for a minimum period of

time of about 150ns (LEB) after the high-side switch is

turned on to allow the system to settle. The Leading Edge

Blanking (LEB) period prevents the detection of erroneous

voltages at the comparator inputs due to switching noise. If

the inductor current exceeds the maximum current limit

(I

LMAX

) a secondary over-current comparator will terminate

the high-side switch on time. If I

LMAX

has not been reached,

the feedback voltage FB derived from the regulator output

voltage V

OUT

is then compared to the internal feedback

reference voltage. The resultant error voltage is summed

with the current feedback and slope compensation ramp.

The high-side switch remains on until all four comparator

inputs have summed to zero, at which time the high-side

switch is turned off and the low-side switch is turned on.

However, the maximum on-duty ratio of the high-side switch

is limited to 95%. In order to eliminate cross-conduction of

the high-side and low-side switches a 15ns break-before-

make delay is incorporated in the switch drive circuitry. The

output enable (EN) input allows the regulator output to be

disabled by an external logic control signal.

Output Voltage Setting

In general:

However, due to the relatively low open loop gain of the

system, gain errors will occur as the output voltage and loop-

gain is changed. This is shown in the performance curves. A

100nA pull-up current from FB to V

DD

forces V

OUT

to GND

in the event that FB is floating.

NMOS Power FETs and Drive Circuitry

The EL7562 integrates low on-resistance (60m

Ω

) NMOS

FETs to achieve high efficiency at 2A. In order to use an

NMOS switch for the high-side drive it is necessary to drive

the gate voltage above the source voltage (LX). This is

accomplished by bootstrapping the V

HI

pin above the LX

voltage with an external capacitor C

VHI

and internal switch

and diode. When the low-side switch is turned on and the LX

voltage is close to GND potential, capacitor C

VHI

is charged

through internal switch to V

DRV

, typically 5V. At the

beginning of the next cycle the high-side switch turns on and

the LX pins begin to rise from GND to V

IN

potential. As the

LX pin rises the positive plate of capacitor C

VHI

follows and

eventually reaches a value of V

DRV

+V

IN

, typically 10V, for

V

DRV

=V

IN

=5V. This voltage is then level shifted and used to

drive the gate of the high-side FET, via the V

HI

pin. A value

of 0.1μF for C

VHI

is recommended.

Reference

A 1.5% temperature compensated bandgap reference is

integrated in the EL7562. The external V

REF

capacitor acts

as the dominant pole of the amplifier and can be increased

in size to maximize transient noise rejection. A value of

0.1μF is recommended.

Oscillator

The system clock is generated by an internal relaxation

oscillator with a maximum duty-cycle of approximately 95%.

Operating frequency can be adjusted through the C

OSC

pin

or can be driven by an external source. If the oscillator is

driven by an external source care must be taken in selecting

the ramp amplitude. Since C

SLOPE

value is derived from the

C

OSC

ramp, changes to C

OSC

ramp will change the

C

SLOPE

compensation ramp which determine the open-loop

gain of the system.

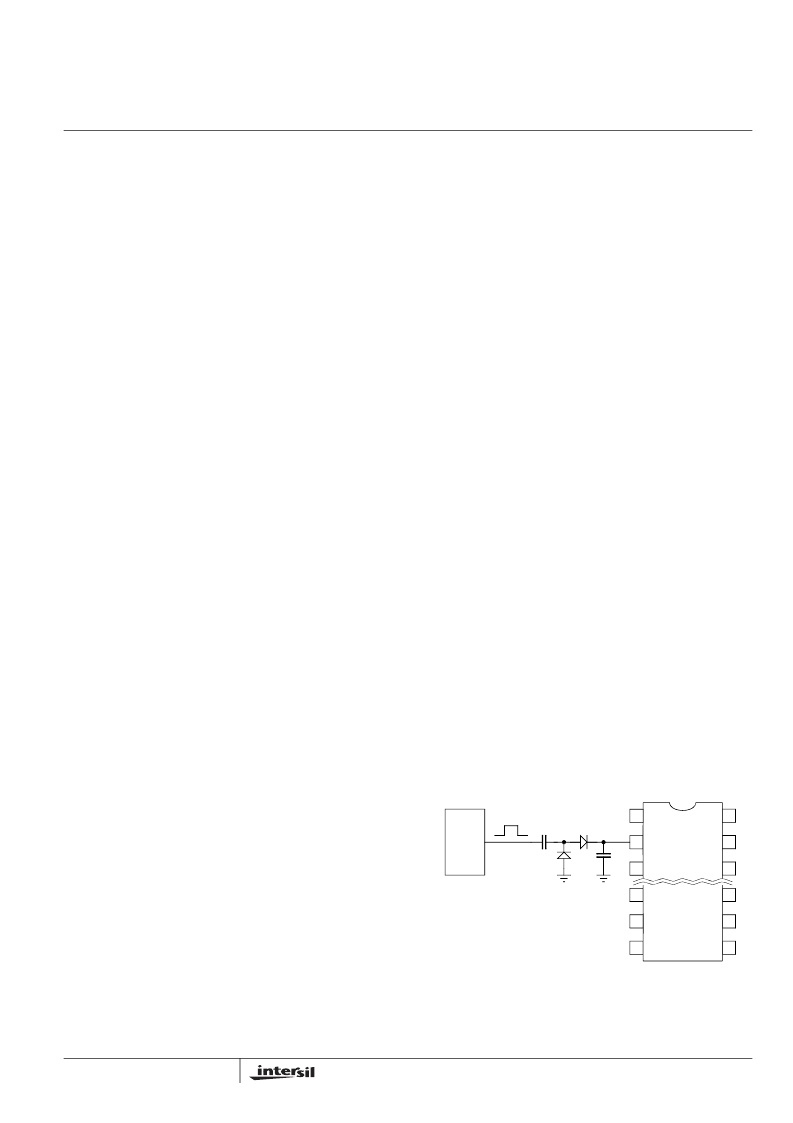

When external synchronization is required, always choose

C

OSC

such that the free-running frequency is at least 20%

lower than that of sync source to accommodate component

and temperature variations. Figure 1 shows a typical

connection.

V

OUT

0.985

1

R

2

R

1

------

+

×

=

For V

IN

= 5V

V

OUT

0.975

1

R

2

R

1

------

+

×

=

FOR V

IN

= 3.3V

FIGURE 1. OSCILLATOR SYNCHRONIZATION

2

3

11

10

9

6

7

8

15

14

EL7562

1

16

External

Oscillato

BAT54

100p

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| EL7562CUZ-T13 | Monolithic 2Amp DC-DC Step-Down Regulator |

| EL7562CUZ-T7 | Monolithic 2Amp DC-DC Step-Down Regulator |

| EL7562 | Monolithic 2Amp DC-DC Step-Down Regulator(單片2A DC-DC降壓穩(wěn)壓器) |

| EL7563CM | Monolithic 4 Amp DC:DC Step-Down Regulator |

| EL7563CM-T13 | Monolithic 4 Amp DC:DC Step-Down Regulator |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| EL7562CUZ-T13 | 功能描述:直流/直流開(kāi)關(guān)轉(zhuǎn)換器 2A DC-DC CNVRTR RoHS:否 制造商:STMicroelectronics 最大輸入電壓:4.5 V 開(kāi)關(guān)頻率:1.5 MHz 輸出電壓:4.6 V 輸出電流:250 mA 輸出端數(shù)量:2 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT |

| EL7562CUZ-T7 | 功能描述:直流/直流開(kāi)關(guān)轉(zhuǎn)換器 2A DC-DC CNVRTR RoHS:否 制造商:STMicroelectronics 最大輸入電壓:4.5 V 開(kāi)關(guān)頻率:1.5 MHz 輸出電壓:4.6 V 輸出電流:250 mA 輸出端數(shù)量:2 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT |

| EL7563 | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:Monolithic 4 Amp DC:DC Step-Down Regulator |

| EL7563C | 制造商:ELANTEC 制造商全稱:ELANTEC 功能描述:Monolithic 4 Amp DC:DC Step-down Regulator |

| EL7563CM | 制造商:Rochester Electronics LLC 功能描述: 制造商:Intersil Corporation 功能描述: |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。