- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄296087 > HB14173 (Electronic Theatre Controls, Inc.) Breake Away Header .025(0.64mm) Square Posts PDF資料下載

參數(shù)資料

| 型號(hào): | HB14173 |

| 廠商: | Electronic Theatre Controls, Inc. |

| 英文描述: | Breake Away Header .025(0.64mm) Square Posts |

| 中文描述: | 破開客場頭.025(0.64毫米)方形崗位 |

| 文件頁數(shù): | 7/10頁 |

| 文件大小: | 230K |

| 代理商: | HB14173 |

6

2005 Semtech Corp.

www.semtech.com

POWER MANAGEMENT

SC1462

Capacitor Selection

Capacitor selection is based on both the maximum ac-

ceptable ripple voltage and the maximum tolerable drop

at the output.

Ripple

The peak-to-peak output ripple voltage is dependent on

the following factors:

1) Oscillator frequency

2) ESR of C

OUT

3) Capacitance value of C

OUT

Item 1 is xed and depend on the charge pump device

used. Item 2, and 3 can be optimized for best perfor-

mance and reduction of the output ripple.

The following formula could be used for an approximation

for V

OUT_RIPPLE.

V

OUT Drop

The voltage drop at the output is specied with the follow-

ing equation:

V

OUT_DROP = IOUT × ROUT

R

OUT is dependent on the following factors:

1) Oscillator frequency

2) ESR of C

OUT & CBUCKET

3) Capacitance value of C

OUT and CBUCKET

4) Internal switch resistance (R

SW = Total of all 4 switch

resistances).

A good approximation for calculating the output

resistance is shown below.

Applications Information (Cont.)

This equation can be used to calculate C

BUCKET for a spe-

cic V

OUT when VIN and IOUT are known. The maximum value

for the R

SW from the Electrical Characteristics section on

Page 2 should be used in order to nd a worst-case num-

ber.

Layout Consideration

Standard power board layout should be followed to ensure

proper operation. Any stray inductance should be mini-

mized, this can be achieved by using large power planes

or traces, and reducing the distances between input, out-

put and the load. All components should be placed as

close as possible to the SC1462.

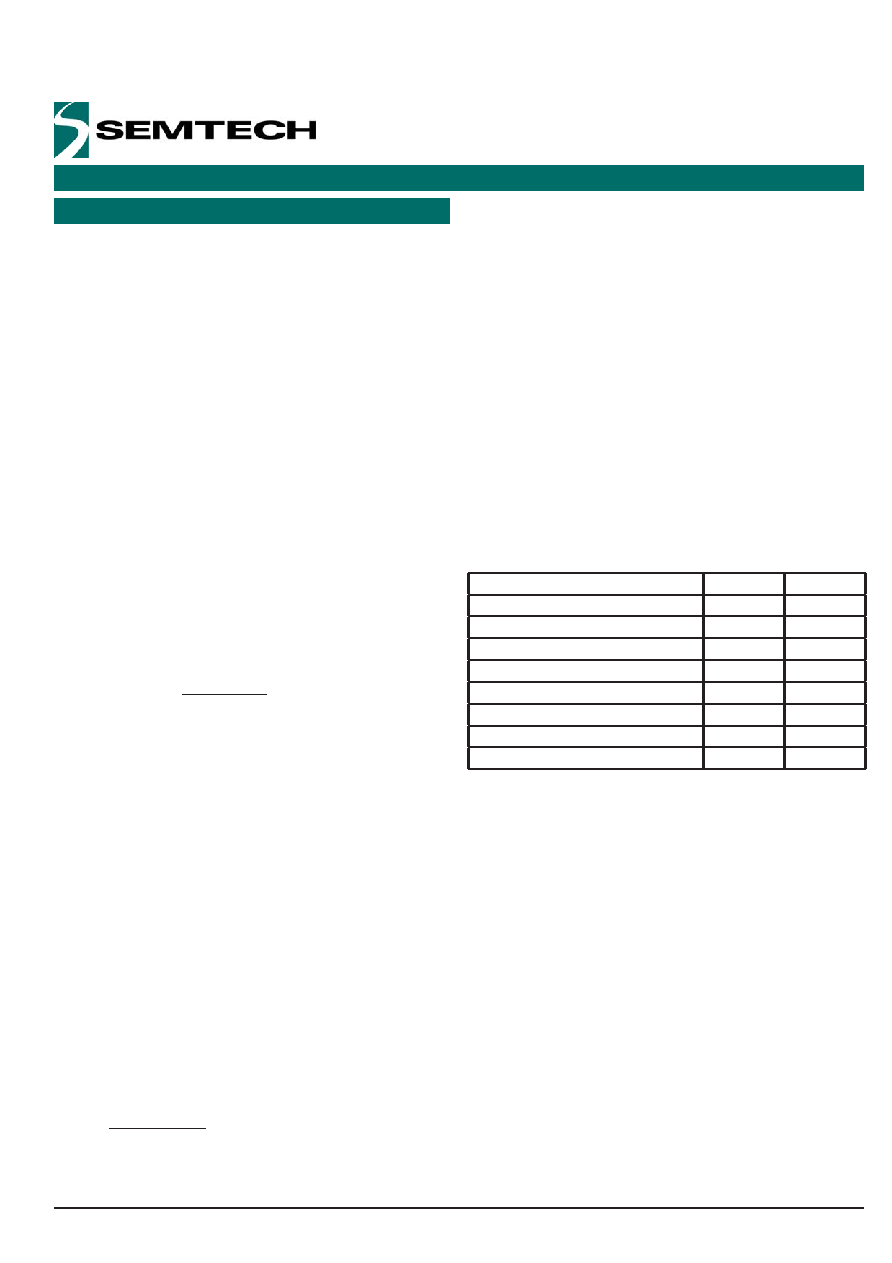

The following table shows typical capacitor characteris-

tics.

V

OUT_RIPPLE =

+ 2 × I × ESR_ C

OUT

2 × f

OSC × COUT

I

OUT

R

OUT =

+ 2 × R

SW + 4 × ESR_ CBUCKET + ESR_ COUT

f

OSC × CBUCKET

1

Component

ESR(

Ω)

ESL(nH)

0.1μF Ceramic 0603 Package

0.050

1.60

1.0μF Ceramic 1206 Package

0.040

0.47

10μF Ceramic 0603 Package

0.075

0.50

47μF Ceramic, 16V Tantalum D case

0.100

0.60

330μF, 6.3V “OSCON”

0.025

2.50

330μF, 16V AL. Electrolytic

0.143

2.37

820μF, 4V “OSCON”

0.012

2.50

1000μF, 10V Al. Electrolytic

0.053

5.00

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HB288032MM1 | FLASH 2.7V PROM CARD, XMA7 |

| HB28A896IA1 | 448M X 16 FLASH 5V PROM CARD, XMA68 |

| HB56A232BW-6C | 2M X 32 FAST PAGE DRAM MODULE, 60 ns, SMA72 |

| HB56U432SB-5N | 4M X 32 EDO DRAM MODULE, 50 ns, SMA72 |

| HBCC-471J-02 | 1 ELEMENT, 470 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HB14177 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Breake Away Header .025(0.64mm) Square Posts |

| HB14180 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Breake Away Header .025(0.64mm) Square Posts |

| HB14181 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Breake Away Header .025(0.64mm) Square Posts |

| HB14183 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Breake Away Header .025(0.64mm) Square Posts |

| HB14187 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Breake Away Header .025(0.64mm) Square Posts |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。