- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄360861 > INA104 Very-High Accuracy INSTRUMENTATION AMPLIFIER PDF資料下載

參數(shù)資料

| 型號(hào): | INA104 |

| 元件分類: | 測(cè)量放大器 |

| 英文描述: | Very-High Accuracy INSTRUMENTATION AMPLIFIER |

| 中文描述: | 甚高精度儀表放大器 |

| 文件頁數(shù): | 7/11頁 |

| 文件大?。?/td> | 132K |

| 代理商: | INA104 |

7

INA104

DISCUSSION

OF PERFORMANCE

INSTRUMENTATION AMPLIFIERS

Instrumentation amplifiers are closed-loop gain blocks whose

committed circuitry accurately amplifies the voltage applied

to their inputs. They respond only to the difference between

the two input signals and exhibit extremely high input imped-

ance, both differentially and common-mode. Feedback net-

works are packaged within the amplifier module. Only one

external gain setting resistor must be added. An operational

amplifier, on the other hand, is an open-loop, uncommitted

device that requires external networks to close the loop.

While operational amplifiers can be used to achieve the same

basic function as instrumentation amplifiers, it is difficult to

reach the same level of performance. Using operational

amplifiers often leads to design trade-offs when it is neces-

sary to amplify low level signals in the presence of common-

mode voltages while maintaining high input impedances.

THE INA104

A simplified schematic of the INA104 is shown on the front

pages of this data sheet. It is a three-amplifier device which

provides all the desirable characteristics of a premium per-

formance instrumentation amplifier. In addition, it has fea-

tures not normally found on integrated circuit instrumenta-

tion amplifiers.

The input section (A

1

and A

2

) incorporates high perfor-

mance, low drift amplifier circuitry. The amplifiers are

connected in the non-inverting configuration to provide the

high input impedance (10

10

) desirable in the instrumenta-

tion amplifier function. The offset voltage and offset voltage

versus temperature is low due to the monolithic design and

improved even further by the state-of-the-art, laser-trimming

techniques.

The output section (A

3

) is connected in a unity-gain differ-

ence amplifier configuration. A critical part of this stage is

the matching of the four 10k

resistors which provide the

difference function. These resistors must be initially well

matched and the matching must be maintained over tem-

perature and time in order to retain excellent common-mode

rejection. (The 106dB minimum at 60Hz for gains greater

than 100V/V is a significant improvement compared to most

other integrated circuit instrumentation amplifiers.)

All of the internal resistors are compatible, thin-film nichrome

formed with the integrated circuit. The critical resistors are

laser-trimmed to provide the desired high gain accuracy and

common-mode rejection. Nichrome ensures long-term sta-

bility of trimmed resistors and excellent TCR and TCR

tracking. This provides gain accuracy and common-mode

rejection when the INA104 is operated over wide tempera-

ture ranges.

The fourth op amp (A

4

) of the INA104 adds a great deal of

versatility and convenience to the amplifier. It allows easy

implementation of active low-pass filtering, output offset-

ting, and additional gain generation. The pin connections

make the use of this stage optional and the specifications

appear separately in the table of Specifications.

USING THE INA104

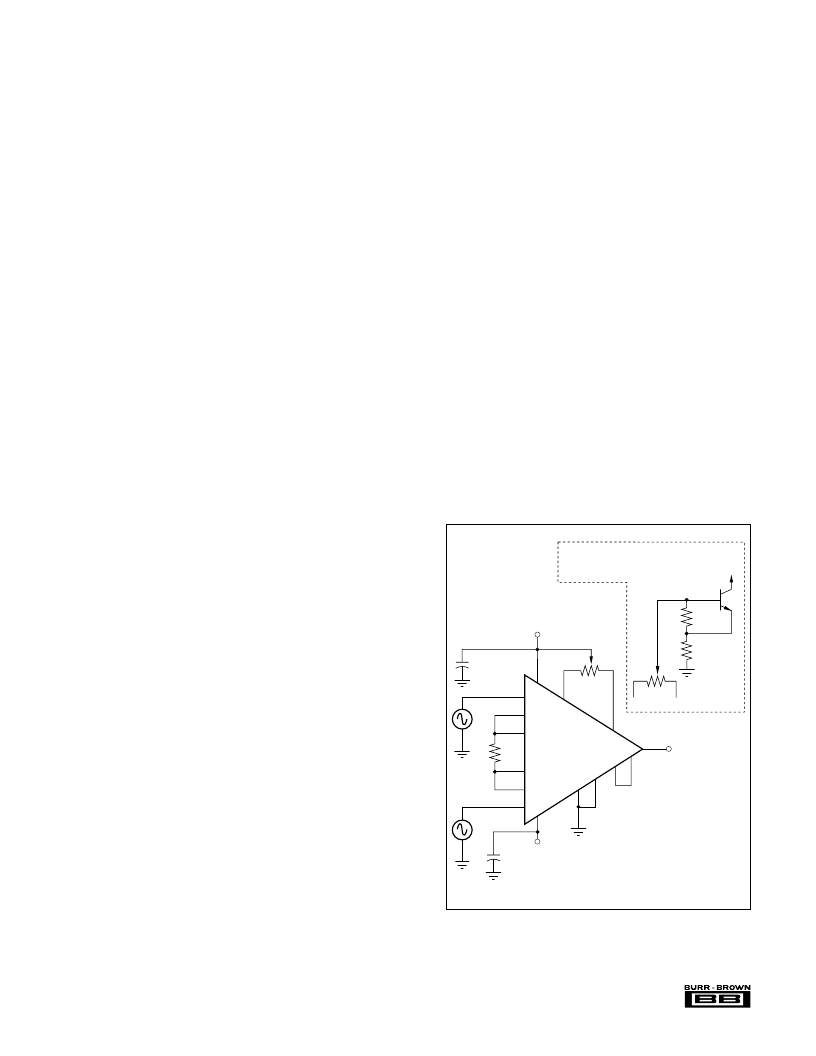

Figure 1 shows the simplest configuration of the

INA104. The gain is set by the external resistor, R

G

,

with a gain equation of G = 1 + (40k/R

G

). The

accuracy and TCR of R

G

contribute directly to the gain

accuracy and drift.

For gains greater than unity, resistor R

G

is connected

between pins 5 and 14. At high gains, where the value of

R

G

becomes small, additional resistance (i.e., relays,

sockets) in series with R

G

will contribute to gain error.

Care should be taken to minimize this effect. However,

this error can be virtually eliminated with the INA104 by

using the Gain Sense circuit connection.

Pins 1, 5, 14, and 18 are accessible so that a four-

terminal connection can be made to R

G

. (Pins 1 and 18

are the voltage sense terminals, since no signal current

flows into the operational amplifiers’ inputs.) This is

useful at high gains, where the value of R

G

is small.

The optional offset adjust capability is shown in

Figure 1. The adjustment affects only the input stage

component of the offset voltage. Thus, the null con-

dition will be disturbed (if input offset is not adjusted

to zero) when the gain is changed. Also, the input

drift will be affected by approximately 0.31

μ

V/

°

C

per 100

μ

V of input offset voltage that is trimmed.

Therefore, care should be taken when considering use

of the control for removal of other sources of offset.

FIGURE 1. Basic Connection for the INA104 Including

Optional Input Offset Null Potentiometer.

3

7

10

11

6

8

13

15

16

17

18

14

5

1

2

INA104

R

G

100k

E

OUT

E

1

E

2

+V

CC

–V

CC

(1)

1μF

Tantalum

1μF

Tantalum

NOTE: (1) Connect pin 7 to common and pin 10

to pin 11 when Internal Amp A

4

is not used.

Gain Sense

Gain Sense

Optional

Offset

Adjust

This circuit may be used as replacement for

the single potentiometer. It will adjust offset

and leave drift unchanged.

+V

CC

15

16

100k

10M

2M

E

OUT

= [1 = (40k/R

G

)] (E

2

– E

1

)

–In

+In

2N2222

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| INA104AM | RES THKF 0805 .125W 5% 680 OHM ROHS |

| INA104BM | Very-High Accuracy INSTRUMENTATION AMPLIFIER |

| INA104CM | Very-High Accuracy INSTRUMENTATION AMPLIFIER |

| INA104SM | Very-High Accuracy INSTRUMENTATION AMPLIFIER |

| INA104 | Very-High Accuracy Instrumentation Amplifier(非常高精度的儀用放大器) |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| INA104AM | 制造商:BB 制造商全稱:BB 功能描述:Very-High Accuracy INSTRUMENTATION AMPLIFIER |

| IN-A-104B-H/MS-PC-212 | 制造商:Hirose 功能描述:901-1090-9-00 EACH 制造商:Hirose 功能描述:IN-A-104B-H/MS-PC-212 |

| INA104BM | 制造商:BB 制造商全稱:BB 功能描述:Very-High Accuracy INSTRUMENTATION AMPLIFIER |

| INA104CM | 制造商:BB 制造商全稱:BB 功能描述:Very-High Accuracy INSTRUMENTATION AMPLIFIER |

| INA104SM | 制造商:BB 制造商全稱:BB 功能描述:Very-High Accuracy INSTRUMENTATION AMPLIFIER |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。