- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄358001 > IRF-2433UH+/-10% (VISHAY DALE) 1 ELEMENT, 33 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR PDF資料下載

參數(shù)資料

| 型號: | IRF-2433UH+/-10% |

| 廠商: | VISHAY DALE |

| 元件分類: | 通用定值電感 |

| 英文描述: | 1 ELEMENT, 33 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

| 封裝: | AXIAL LEADED |

| 文件頁數(shù): | 1/1頁 |

| 文件大小: | 78K |

www.vishay.com

33

IRF-24

Vishay Dale

Document Number 34056

Revision 07-Dec-01

For technical questions, contact Magnetics@vishay.com

FEATURES

High performance ferrite core is used in this epoxy conformally

coated choke which allows for inductance values to 1000

μ

H.

Axial lead type, small lightweight design.

Special magnetic core structure contributes to high Q and

self-resonant frequencies.

Treated with epoxy resin coating for humidity resistance to

ensure long life.

Heat resistant adhesives.

Inductors

Epoxy Conformal Coated, Axial Leaded

STANDARD ELECTRICAL SPECIFICATIONS

SELF-

RES.

TEST

FREQ. FREQ.

L & Q

(MHz)

25.2

25.2

25.2

25.2

25.2

25.2

25.2

25.2

25.2

25.2

25.2

25.2

25.2

7.96

7.96

7.96

7.96

7.96

7.96

7.96

7.96

7.96

7.96

7.96

7.96

2.52

2.52

2.52

2.52

2.52

2.52

2.52

2.52

2.52

2.52

2.52

2.52

0.796

0.796

0.796

0.796

0.796

0.796

0.796

0.796

0.796

0.796

0.796

0.796

RATED

DC

CURRENT

(mA)

1400

1350

1270

1200

1150

1110

1110

1000

1000

950

900

900

815

740

700

655

630

595

575

555

530

500

470

425

370

350

335

315

285

270

255

240

205

195

185

175

165

160

150

140

130

120

100

95

90

85

75

65

60

DCR

MAX.

(Ohms)

0.085

0.085

0.095

0.12

0.15

0.15

0.15

0.17

0.17

0.17

0.18

0.18

0.18

0.18

0.20

0.23

0.25

0.28

0.30

0.32

0.35

0.40

0.45

0.56

0.72

0.80

0.88

1.0

1.2

1.35

1.50

1.70

2.30

2.60

2.90

3.20

3.70

3.80

4.90

5.0

6.50

7.5

9.5

10.5

17.5

18.5

20.0

23.7

30.0

IND.

(

μ

H)

0.10

0.12

0.15

0.18

0.22

0.27

0.33

0.39

0.47

0.56

0.68

0.82

1.0

1.2

1.5

1.8

2.2

2.7

3.3

3.9

4.7

5.6

6.8

8.2

10

12

15

18

22

27

33

39

47

56

68

82

100

120

150

180

220

270

330

390

470

560

680

820

1000

Q

MIN.

(MHz)

280

280

280

280

280

260

260

220

200

180

160

140

135

135

130

125

80

80

70

65

45

40

30

28

22

20

16

15

13

11

10

9.5

8.5

7.5

6.5

6.0

5.5

5.4

4.75

4.35

4.0

3.7

3.4

2.8

2.56

2.35

2.0

1.60

1.15

TOL.

MIN.

30

30

30

30

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

50

50

50

50

50

60

60

60

60

60

60

60

60

60

60

60

50

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

±

5%,

±

10%

ELECTRICAL SPECIFICATIONS

Inductance Range:

0.1

μ

H to 1000

μ

H.

Inductance Tolerance:

±

10% from 0.1

μ

H to 1000

μ

H

standard,

±

5% optional.

Operating Temperature Range:

- 20

°

C to + 105

°

C.

Dielectric Strength:

250V RMS.

MECHANICAL SPECIFICATIONS

Terminal Strength:

Pull = 5 pounds. Twist = 360

°

C x 3.

Protection:

Epoxy uniform roll coated.

Leads:

Tinned copper.

ENVIRONMENTAL SPECIFICATIONS

Maximum Temperature Rise:

+ 20

°

C.

ORDERING INFORMATION

IRF-24

MODEL

±

10%

INDUCTANCE

TOLERANCE

6.8

μ

H

INDUCTANCE

VALUE

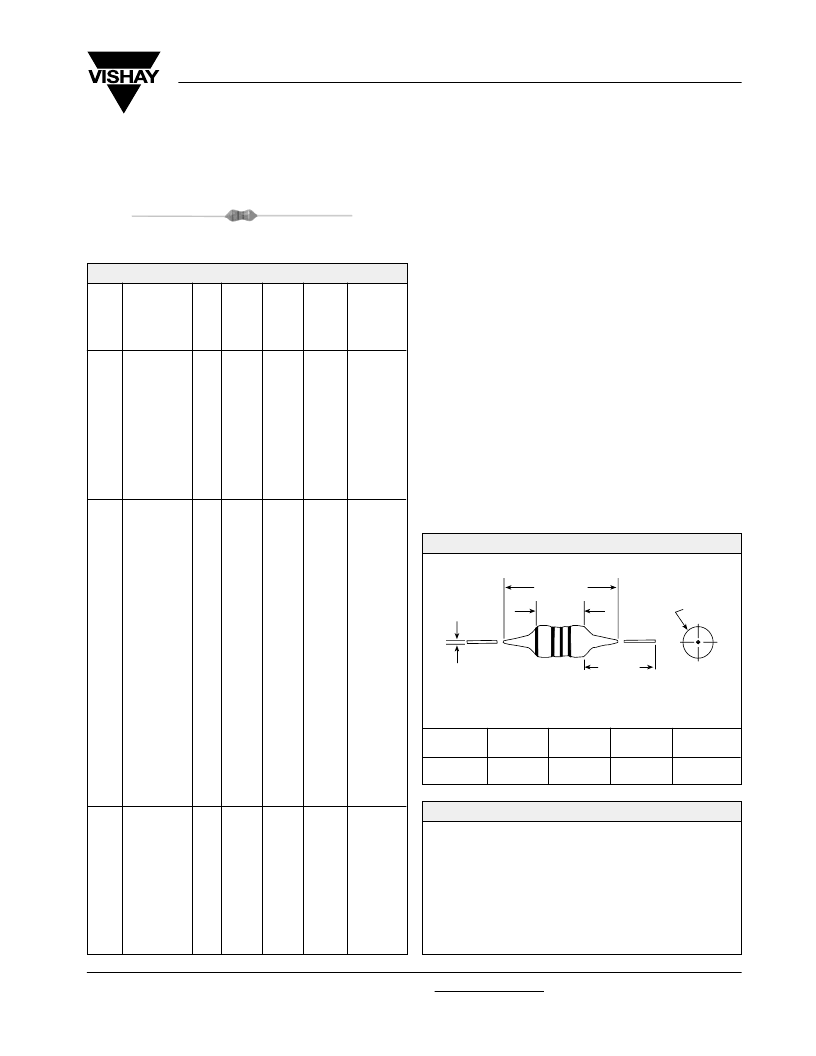

DIMENSIONS

in inches [millimeters]

A

B

C

D

MODEL

IRF-24

(Max.)

0.157

[4.0]

(Max.)

0.118

[3.0]

(Max.)

0.394

[10.0]

(Max.)

0.020

[0.5]

A (Max.)

B

(Max.)

D

(Max.)

C (Max.)

0.98 [25.0]

Min.

1.22 [31.0]

Max.

相關PDF資料 |

PDF描述 |

|---|---|

| IRF-24390UH+/-10% | 1 ELEMENT, 390 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

| IRF-360.12UH+/-5% | 1 ELEMENT, 0.12 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

| IRF241R | 18 A, 150 V, 0.18 ohm, N-CHANNEL, Si, POWER, MOSFET, TO-204AE |

| IRF242R | 16 A, 200 V, 0.22 ohm, N-CHANNEL, Si, POWER, MOSFET, TO-204AE |

| IRF320 | 3.3 A, 400 V, 1.8 ohm, N-CHANNEL, Si, POWER, MOSFET, TO-204AA |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| IRF243R | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:TRANSISTOR | MOSFET | N-CHANNEL | 150V V(BR)DSS | 16A I(D) | TO-204AE |

| IRF244 | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| IRF245 | 制造商:Rochester Electronics LLC 功能描述:- Bulk 制造商:International Rectifier 功能描述: |

| IRF246 | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:14A and 13A, 275V and 250V, 0.28 and 0.34 Ohm, N-Channel Power MOSFETs |

| IRF247 | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:14A and 13A, 275V and 250V, 0.28 and 0.34 Ohm, N-Channel Power MOSFETs |

發(fā)布緊急采購,3分鐘左右您將得到回復。