- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄377518 > IRG4PF40KD (International Rectifier) Fit Rate / Equivalent Device Hours PDF資料下載

參數(shù)資料

| 型號: | IRG4PF40KD |

| 廠商: | International Rectifier |

| 英文描述: | Fit Rate / Equivalent Device Hours |

| 中文描述: | FIT率/等效器件小時 |

| 文件頁數(shù): | 26/35頁 |

| 文件大小: | 112K |

| 代理商: | IRG4PF40KD |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁當(dāng)前第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁

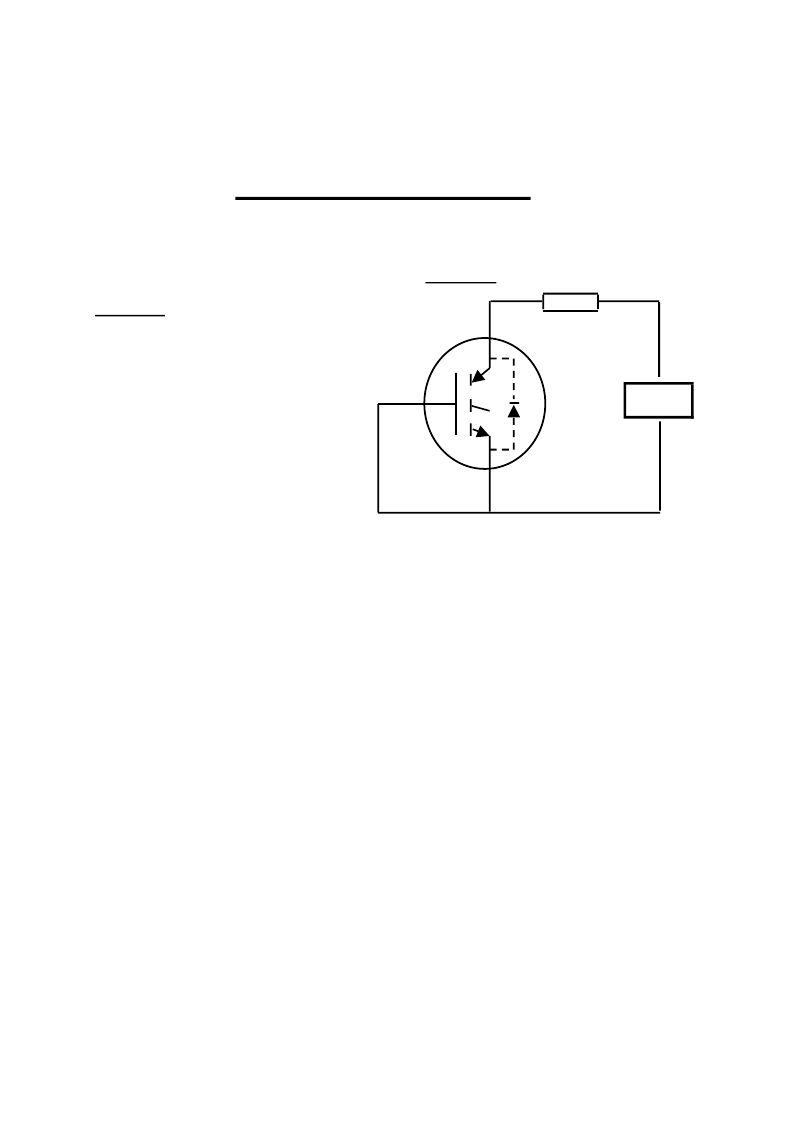

TEMPERATURE & HUMIDITY (THB)

Test circuit

Conditions

Bias:

Vce = 100% of maximum rated

V

up to 500V: 500V for

all devices with rated

V

(BR)CES

greater than 500V *

85°C

85%

2000 Hours nominal

168, 500, 1000,

1500, 2000 Hours nominal.

DUT

DC

BIAS

Temperature:

Relative Humidity:

Duration:

Test points:

* Devices manufactured since week

code 9640 the applied bias:

V

(BR)CES

=

Vmax or 100v which ever the lesser

D

= Diode for CoPack devices only

Purpose

Failure Modes

Sensitive Parameters

V

(BR)CES,

V

CE(on)

Temperature and Humidity bias testing for non-hermetic packages is to subject the

devices to extremes of temperature and humidity to examine the ability of the

package to withstand the deleterious effect of the humid environment.

D

There are two primary failure modes which have been observed. The first failure

mode comes about as a result of the ingression of water molecules into the active

area on the surface of the die. Once sufficient water has accumulated in the region

of the electric field termination structure on the die, the perturbation of that field

begins to degrade the breakdown characteristics of the device.

The second failure mode that has been observed is due to cathodic corrosion of the

aluminum emitter bonding pad. As with first failure mode, water will ingress to the top

of the die. There, in the presence of applied bias, an electric current through the few

monolayers of water will begin to cause the bond pad to dissolve. Eventually. the

corrosion will proceed to the point where the current capability of the device is

increased and become unstable.

The dominance of either of these failure modes is basically determined by the

amount of bias present during test.

Under low bias conditions, the corrosion

proceeds slowly, so the first failure mode will proceed very rapidly and the device will

fail due to on-resistance before the breakdown characteristics can degrade.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| IRG4PF40MD | Fit Rate / Equivalent Device Hours |

| IRG4PF40SD | Fit Rate / Equivalent Device Hours |

| IRG4PF40UD | Fit Rate / Equivalent Device Hours |

| IRG4PG40FD | Fit Rate / Equivalent Device Hours |

| IRG4PG40KD | Fit Rate / Equivalent Device Hours |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| IRG4PF40MD | 制造商:IRF 制造商全稱:International Rectifier 功能描述:Fit Rate / Equivalent Device Hours |

| IRG4PF40SD | 制造商:IRF 制造商全稱:International Rectifier 功能描述:Fit Rate / Equivalent Device Hours |

| IRG4PF40UD | 制造商:IRF 制造商全稱:International Rectifier 功能描述:Fit Rate / Equivalent Device Hours |

| IRG4PF50W | 制造商:International Rectifier 功能描述:IGBT TO-247 |

| IRG4PF50WD | 制造商:International Rectifier 功能描述:IGBT TO-247 |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。