- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄358818 > LM2574HVN-ADJ (NATIONAL SEMICONDUCTOR CORP) SIMPLE SWITCHER⑩ 0.5A Step-Down Voltage Regulator PDF資料下載

參數(shù)資料

| 型號(hào): | LM2574HVN-ADJ |

| 廠商: | NATIONAL SEMICONDUCTOR CORP |

| 元件分類: | 穩(wěn)壓器 |

| 英文描述: | SIMPLE SWITCHER⑩ 0.5A Step-Down Voltage Regulator |

| 中文描述: | 1.8 A SWITCHING REGULATOR, 63 kHz SWITCHING FREQ-MAX, PDIP8 |

| 封裝: | DIP-8 |

| 文件頁(yè)數(shù): | 19/24頁(yè) |

| 文件大小: | 397K |

| 代理商: | LM2574HVN-ADJ |

第1頁(yè)第2頁(yè)第3頁(yè)第4頁(yè)第5頁(yè)第6頁(yè)第7頁(yè)第8頁(yè)第9頁(yè)第10頁(yè)第11頁(yè)第12頁(yè)第13頁(yè)第14頁(yè)第15頁(yè)第16頁(yè)第17頁(yè)第18頁(yè)當(dāng)前第19頁(yè)第20頁(yè)第21頁(yè)第22頁(yè)第23頁(yè)第24頁(yè)

LM2574

19

MOTOROLA ANALOG IC DEVICE DATA

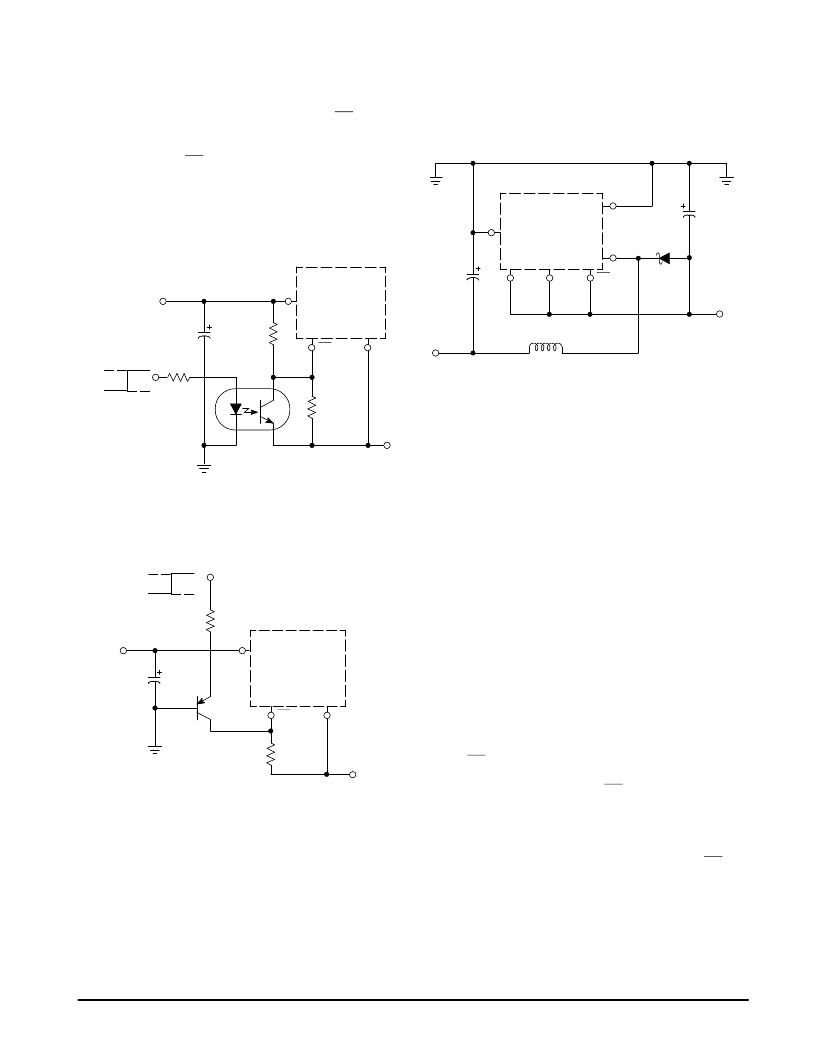

applied to a buck–boost converter is shown in Figure 28.

Figure 34 in the “Undervoltage Lockout” section describes an

undervoltage lockout feature for the same converter

topology.

With the inverting configuration, the use of the ON/OFF pin

requires some level shifting techniques. This is caused by the

fact, that the ground pin of the converter IC is no longer at

ground. Now, the ON/OFF pin threshold voltage (1.3 V

approximately) has to be related to the negative output

voltage level. There are many different possible shutdown

methods, two of them are shown in Figures 29 and 30.

LM2574–XX

5

2

and

4

3

Gnds

Pins

ON/OFF

+Vin

R2

47 k

Cin

22

μ

F

NOTE

: This picture does not show the complete circuit.

R1

47 k

R3

470

Shutdown

Input

MOC8101

–Vout

Off

On

5.0 V

0

+Vin

Figure 29. Inverting Buck–Boost Regulator Shutdown

Circuit Using an Optocoupler

NOTE

: This picture does not show the complete circuit.

R2

5.6 k

Q1

2N3906

LM2574–XX

5

2

and

4

3

Gnds

Pins

ON/OFF

R1

12 k

–Vout

+Vin

Shutdown

Input

Off

On

+V

0

+Vin

Cin

22

μ

F

Figure 30. Inverting Buck–Boost Regulator Shutdown

Circuit Using a PNP Transistor

Negative Boost Regulator

This example is a variation of the buck–boost topology and

it is called negative boost regulator. This regulator

experiences relatively high switch current, especially at low

input voltages. The internal switch current limiting results in

lower output load current capability.

The circuit in Figure 31 shows the negative boost

configuration. The input voltage in this application ranges

from –5.0 to –12 V and provides a regulated –12 V output. If

the input voltage is greater than –12 V, the output will rise

above –12 V accordingly, but will not damage the regulator.

1N5817

330

μ

H

Output

7

1

Feedback

Vout = –12 V

Load Current

60 mA for Vin = –5.2 V

120 mA for Vin = –7.0 V

Vin

L1

D1

Cout

1000

μ

F

Cin

22

μ

F

LM2574–12

5

3

4

ON/OFF

Pwr

Gnd

+Vin

2

Sig

Gnd

–5.0 to –12 V

Figure 31. Negative Boost Regulator

Design Recommendations:

The same design rules as for the previous inverting

buck–boost converter can be applied. The output capacitor

Cout must be chosen larger than what would be required for a

standard buck converter. Low input voltages or high output

currents require a large value output capacitor (in the range

of thousands of

μ

F). The recommended range of inductor

values for the negative boost regulator is the same as for

inverting converter design.

Another important point is that these negative boost

converters cannot provide any current limiting load protection

in the event of a short in the output so some other means,

such as a fuse, may be necessary to provide the load

protection.

Delayed Startup

There are some applications, like the inverting regulator

already mentioned above, which require a higher amount of

startup current. In such cases, if the input power source is

limited, this delayed startup feature becomes very useful.

To provide a time delay between the time when the input

voltage is applied and the time when the output voltage

comes up, the circuit in Figure 32 can be used. As the input

voltage is applied, the capacitor C1 charges up, and the

voltage across the resistor R2 falls down. When the voltage

on the ON/OFF pin falls below the threshold value 1.3 V, the

regulator starts up. Resistor R1 is included to limit the

maximum voltage applied to the ON/OFF pin. It reduces the

power supply noise sensitivity, and also limits the capacitor

C1 discharge current, but its use is not mandatory.

When a high 50 Hz or 60 Hz (100 Hz or 120 Hz

respectively) ripple voltage exists, a long delay time can

cause some problems by coupling the ripple into the ON/OFF

pin, the regulator could be switched periodically on and off

with the line (or double) frequency.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| LM2574M-ADJ | SIMPLE SWITCHER⑩ 0.5A Step-Down Voltage Regulator |

| LM2574M-3.3 | SIMPLE SWITCHER⑩ 0.5A Step-Down Voltage Regulator |

| LM2574M-15 | Precision Chopper-Stabilized Operational Amplifier 8-PDIP |

| LM2574M-5.0 | SIMPLE SWITCHER⑩ 0.5A Step-Down Voltage Regulator |

| LM2574N-3.3 | SIMPLE SWITCHER⑩ 0.5A Step-Down Voltage Regulator |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| LM2574HVN-ADJ | 制造商:Texas Instruments 功能描述:IC SWITCHING REG ADJ 2574 DIP8 |

| LM2574HVN-ADJ/NOPB | 功能描述:直流/直流開(kāi)關(guān)轉(zhuǎn)換器 0.5A STEP-DOWN VLTG REG RoHS:否 制造商:STMicroelectronics 最大輸入電壓:4.5 V 開(kāi)關(guān)頻率:1.5 MHz 輸出電壓:4.6 V 輸出電流:250 mA 輸出端數(shù)量:2 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT |

| LM2574HVN-ADJ-ND | 制造商:National Semiconductor Corporation 功能描述: |

| LM2574M-12 | 功能描述:直流/直流開(kāi)關(guān)轉(zhuǎn)換器 RoHS:否 制造商:STMicroelectronics 最大輸入電壓:4.5 V 開(kāi)關(guān)頻率:1.5 MHz 輸出電壓:4.6 V 輸出電流:250 mA 輸出端數(shù)量:2 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT |

| LM2574M-12/NOPB | 功能描述:直流/直流開(kāi)關(guān)轉(zhuǎn)換器 RoHS:否 制造商:STMicroelectronics 最大輸入電壓:4.5 V 開(kāi)關(guān)頻率:1.5 MHz 輸出電壓:4.6 V 輸出電流:250 mA 輸出端數(shù)量:2 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。