- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄358901 > LNSK20 (Electronic Theatre Controls, Inc.) NTC Thermistor SMD PDF資料下載

參數(shù)資料

| 型號: | LNSK20 |

| 廠商: | Electronic Theatre Controls, Inc. |

| 元件分類: | 熱敏電阻 |

| 英文描述: | NTC Thermistor SMD |

| 中文描述: | NTC熱敏電阻貼片 |

| 文件頁數(shù): | 7/10頁 |

| 文件大小: | 228K |

| 代理商: | LNSK20 |

Item

Test Method

Criteria for judging

RELIABILITY TEST METHOD

Resistance to Soldering

Heat Test

Solderability Test

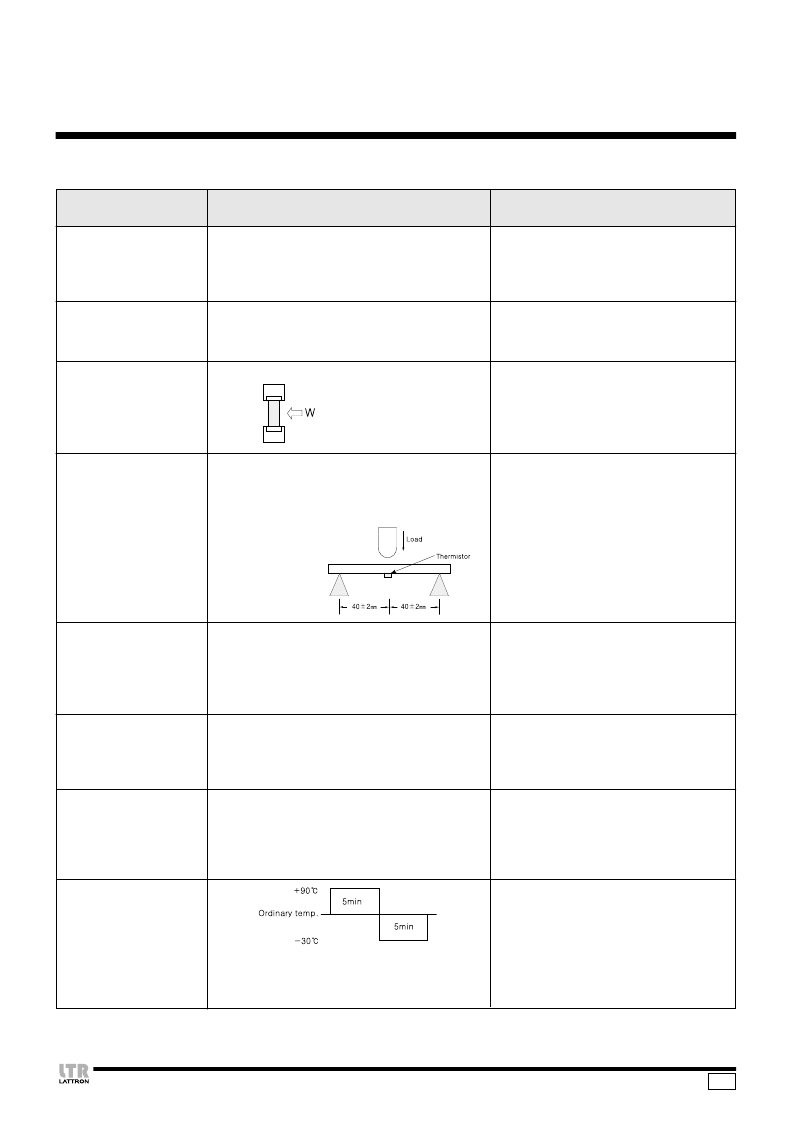

Adhesion

Resistance to

flexure of substrate

Dry Heat Test

Cold Test

Damp Heat Test

(Steady State)

Thermal shock Test

Soldering temperature : 260

5

o

C

Duration of immersion : 10

1sec.

Preheating : 150

, 1min.

Soldering temperature : 230

5

o

C

Duration of immersion : 5

1sec.

Preheating : 150

o

C

, 1min.

Force W is applied to DUT.

The middle part of substrate shall, successively, be

pressurized by means of the pressurizing rod at a rate

of about 1

§fi

/sec.

Maintenance time : 5 sec.

Bending distance : 1

§fi

Test temperature :

125

2

o

C

, 85

2

o

C

(R-T curve Z)

Test duration : 1000+48hrs.

After completion of the test, leaving the sample under

the standard conditions for 24

2hrs.

Test temperature : -30

2

o

C

Test duration : 1000+48hrs.

After completion of the test, leaving the sample under

the standard conditions for 24

2hrs.

Test temperature : 60

2

o

C

Test relative humidity : 90

95RH%

Test duration : 1000+24hrs.

After completion of the test, leaving the sample under

the standard conditions for 24

2hrs.

This cycle is repeated 1000 times. After completion of

the test, allow the sample to stand under the standard

conditions for at 24

2hrs.

Visual : No mechanical damage Zero-power

resistance at 25

o

C

Change as against pretest values within

3%

Change of B-value : within

2%

At least 75% of the electrode must be covered with

new solder.

2012 : over 2.0 kg f

1608 : over 1.0 kg f

1005 : over 0.7 kg f

Visual : No mechanical damage

Zero-power resistance at 25

o

C

:

Change as against pretest values within

3%

Change of B-value : within

2%

Zero-power resistance at 25

o

C

:

Change as against pretest values within

3%

Change of B-value : within

2%

Zero-power resistance at 25

o

C

:

Change as against pretest values within

3%

Change of B-value : within

2%

Zero-power resistance at 25

:

Change as against pretest values within

3%

Change of B-value : within

2%

NTC Thermistor SMD

13

www.lattron.com

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| LNT1E104SEG | ALUMINUM ELECTROLYTIC CAPACITORS |

| LNV304101A | Surface Lighting(15.0 mm ⅴ 12.0 mm Series) |

| LNW497CK4 | 3.0 mm InGaAIP |

| LNW498CK4 | 3.0 mm InGaAIP |

| LNW4A4CN4 | 5.0 mm InGaAIP |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| LNSP15900415 | 制造商:LAMBDA 功能描述:LNSP15 Power Supply Regulated with Factory Manual |

| LNSP-15-9004-15 | 制造商:LAMBDA 功能描述:LNSP15 Power Supply Regulated with Factory Manual |

| LNST10 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:NTC Thermistor SMD |

| LNST16 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:NTC Thermistor SMD |

| LNST20 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:NTC Thermistor SMD |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。