- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄39425 > LTC3547EDDB-1#PBF (LINEAR TECHNOLOGY CORP) 0.7 A DUAL SWITCHING CONTROLLER, 2700 kHz SWITCHING FREQ-MAX, PDSO8 PDF資料下載

參數(shù)資料

| 型號: | LTC3547EDDB-1#PBF |

| 廠商: | LINEAR TECHNOLOGY CORP |

| 元件分類: | 穩(wěn)壓器 |

| 英文描述: | 0.7 A DUAL SWITCHING CONTROLLER, 2700 kHz SWITCHING FREQ-MAX, PDSO8 |

| 封裝: | 3 X 2 MM, 0.75 MM HEIGHT, LEAD FREE, PLASTIC, M0-229WECD-1, DFN-8 |

| 文件頁數(shù): | 15/16頁 |

| 文件大小: | 296K |

| 代理商: | LTC3547EDDB-1#PBF |

LTC3547

8

3547fa

APPLICATIO S I FOR ATIO

WU

U

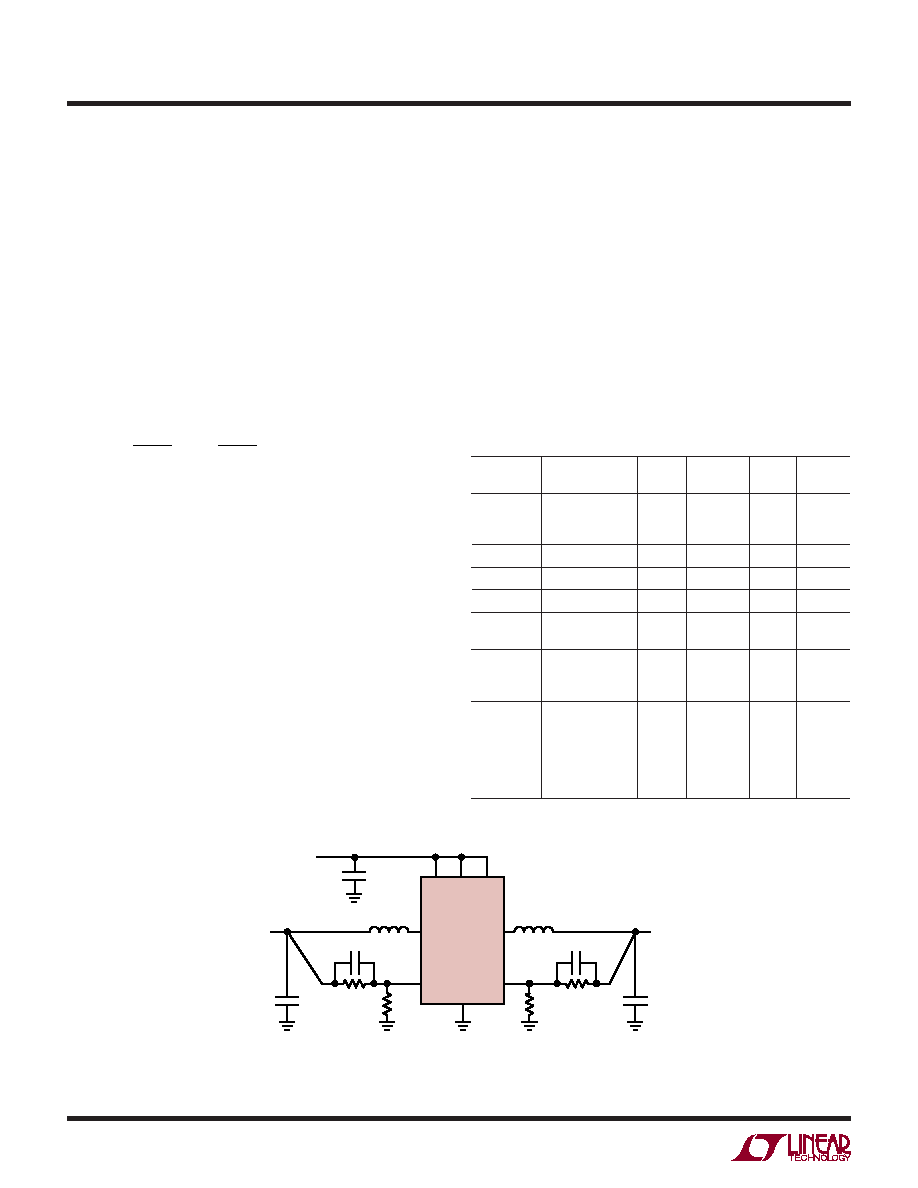

A general LTC3547 application circuit is shown in

Figure 1. External component selection is driven by the

load requirement, and begins with the selection of the

inductor L. Once the inductor is chosen, CIN and COUT

can be selected.

Inductor Selection

Although the inductor does not inuence the operat-

ing frequency, the inductor value has a direct effect on

ripple current. The inductor ripple current ΔIL decreases

with higher inductance and increases with higher VIN

or VOUT:

I

V

fL

V

L

OUT

O

OUT

IN

=

1

(1)

Accepting larger values of ΔIL allows the use of low

inductances, but results in higher output voltage ripple,

greater core losses, and lower output current capability.

A reasonable starting point for setting ripple current

is 40% of the maximum output load current. So, for a

300mA regulator, ΔIL = 120mA (40% of 300mA).

The inductor value will also have an effect on Burst Mode

operation. The transition to low current operation begins

when the peak inductor current falls below a level set by

the internal burst clamp. Lower inductor values result in

higher ripple current which causes the transition to occur

at lower load currents. This causes a dip in efciency in

the upper range of low current operation. Furthermore,

lower inductance values will cause the bursts to occur

with increased frequency.

Inductor Core Selection

Different core materials and shapes will change the

size/current and price/current relationship of an induc-

tor. Toroid or shielded pot cores in ferrite or permalloy

materials are small and do not radiate much energy, but

generally cost more than powdered iron core inductors

with similar electrical characteristics. The choice of which

style inductor to use often depends more on the price vs

size requirements, and any radiated eld/EMI requirements,

than on what the LTC3547 requires to operate. Table 1

shows some typical surface mount inductors that work

well in LTC3547 applications.

Figure 1. LTC3547 General Schematic

CF2

CF1

VIN

2.5V TO 5.5V

VOUT2

VOUT1

3547 F01

R3

R1

R4

L2

L1

R2

COUT2

C1

COUT1

VIN

RUN2

RUN1

LTC3547

VFB2

SW2

SW1

VFB1

GND

Table 1. Representative Surface Mount Inductors

MANU-

FACTURER

PART NUMBER

VALUE

MAX DC

CURRENT

DCR

HEIGHT

Taiyo Yuden

CB2016T2R2M

CB2012T2R2M

CB2016T3R3M

2.2H

3.3H

510mA

530mA

410mA

0.13Ω

0.33Ω

0.27Ω

1.6mm

1.25mm

1.6mm

Panasonic

ELT5KT4R7M

4.7H

950mA

0.2Ω

1.2mm

Sumida

CDRH2D18/LD

4.7H

630mA

0.086Ω

2mm

Murata

LQH32CN4R7M23

4.7H

450mA

0.2Ω

2mm

Taiyo Yuden

NR30102R2M

NR30104R7M

2.2H

4.7H

1100mA

750mA

0.1Ω

0.19Ω

1mm

FDK

FDKMIPF2520D

4.7H

3.3H

2.2H

1100mA

1200mA

1300mA

0.11Ω

0.1Ω

0.08Ω

1mm

TDK

VLF3010AT4R7-

MR70

VLF3010AT3R3-

MR87

VLF3010AT2R2-

M1RD

4.7H

3.3H

2.2H

700mA

870mA

1000mA

0.24Ω

0.17Ω

0.12Ω

1mm

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| LTC3564EDCB#PBF | 2.5 A SWITCHING REGULATOR, 2700 kHz SWITCHING FREQ-MAX, PDSO6 |

| LTC3564IDCB#PBF | 2.5 A SWITCHING REGULATOR, 2700 kHz SWITCHING FREQ-MAX, PDSO6 |

| LTC3604IMSE#PBF | SWITCHING REGULATOR, PDSO16 |

| LTC3604IUD#TRPBF | SWITCHING REGULATOR, PQCC16 |

| LTC3604IUD#PBF | SWITCHING REGULATOR, PQCC16 |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| LTC3548 | 制造商:LINER 制造商全稱:Linear Technology 功能描述:Dual Synchronous,400mA/800mA, 2.25MHz Step-Down DC/DC Regulator |

| LTC3548-1 | 制造商:LINER 制造商全稱:Linear Technology 功能描述:Dual Synchronous, Fixed Output 2.25MHz Step-Down DC/DC Regulator |

| LTC3548-2 | 制造商:LINER 制造商全稱:Linear Technology 功能描述:Dual Synchronous, Fixed/Adjustable Output, 2.25MHz Step-Down DC/DC Regulator |

| LTC3548A | 制造商:LINER 制造商全稱:Linear Technology 功能描述:Dual Synchronous 400mA/800mA, 2.25MHz Step-Down DC/DC Regulator |

| LTC3548AEDD | 制造商:LINER 制造商全稱:Linear Technology 功能描述:Dual Synchronous 400mA/800mA, 2.25MHz Step-Down DC/DC Regulator |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。