- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄296568 > ML235RAG26NGLC (COILCRAFT INC) 1 ELEMENT, 0.026 uH, CERAMIC-CORE, GENERAL PURPOSE INDUCTOR, SMD PDF資料下載

參數(shù)資料

| 型號: | ML235RAG26NGLC |

| 廠商: | COILCRAFT INC |

| 元件分類: | 通用定值電感 |

| 英文描述: | 1 ELEMENT, 0.026 uH, CERAMIC-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| 封裝: | CHIP, 0402 |

| 文件頁數(shù): | 1/2頁 |

| 文件大小: | 183K |

| 代理商: | ML235RAG26NGLC |

1102 Silver Lake Road

Cary IL 60013

Phone

Fax

800-981-0363

847-639-1508

E-mail

Web

cp@coilcraft.com

www.coilcraft-cps.com

Coilcraft, Inc. 2009

These parts are preproduction products for electrical evaluation only.

Specification subject to change without notice.

MilitaryGradeChipInductors ML235RAG

0402 CHIP INDUCTORS

Document ML526-1

Revised 06/25/09

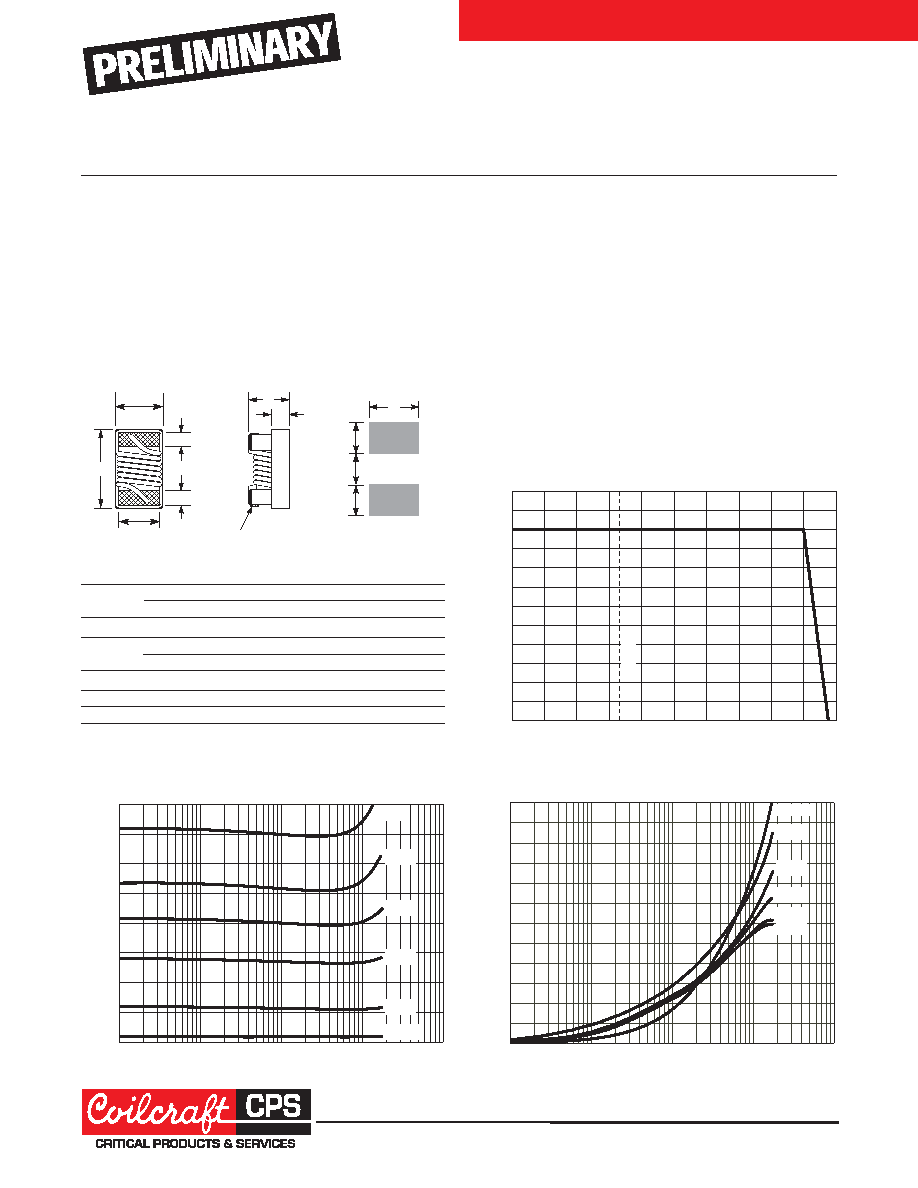

0

60

50

40

30

20

10

70

80

Inductance

(nH)

1

10

100

1000

10000

Frequency (MHz)

51 nH

39 nH

27 nH

11 nH

2.0 nH

68 nH

0

60

50

40

30

20

10

70

80

90

100

110

120

Q

F

actor

1

10

100

1000

10000

Frequency (MHz)

68 nH

51 nH

39 nH

27 nH

11 nH

2.0 nH

Typical L vs Frequency

Typical Q vs Frequency

Core material Ceramic

Terminations Silver-palladium-platinum-glass frit

Weight 0.7 – 1.0 mg

Ambient temperature –55°C to +140°C with

Irms current, +140°C

to +155°C with derated current

Storage temperature Component: –55°C to +155°C.

Packaging: –55°C to +80°C

Resistance to soldering heat Max three 40 second reflows at

+260°C, parts cooled to room temperature between cycles

Temperature Coefficient of Inductance (TCL) +25 to +125 ppm/°C

Moisture Sensitivity Level (MSL) 1 (unlimited floor life at <30°C /

85% relative humidity)

Enhanced Crush-Resitant Packaging 2000 per 7

″ reel.

Paper tape: 8 mm wide, 0.66 mm thick, 2 mm pocket spacing

Current Derating

Higher Q and lower DCR than other 0402 inductors

Very high SRF values – as high as 16 GHz

Excellent current handling capability – up to 2300 mA

52 inductance values from 1.0 to 220 nH

This robust version of Coilcraft’s standard 0402HP

series features high temperature materials that allow

operation in ambient temperatures up to 155°C.

-40

-20

0

20

40

60

80

100

160

140

120

Ambient temperature (°C)

P

e

rcent

of

rated

rmsI

120

110

100

90

80

70

60

50

40

30

20

10

0

25°C

A

B

overall

C

D

I

J

F

G

H

Suggested

Land Pattern

E

terminal

Terminal wraparound:

approx 0.007/0,18 both ends

DE

F

G

H

I

J

0.010

0.020

0.008

0.024

0.026

0.014

0.020

inches

0,25

0,51

0,20

0,61

0,66

0,36

0,51

mm

A max

B

C max

0.043

0.026 ±0.002

0.024

inches

1,09

0,66 ±0,051

0,61

mm

1–51 nH

A max

B

C max

0.044

0.026 ±0.002

0.026

inches

1,12

0,66 ±0,051

0,66

mm

56–220 nH

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| ML235RAG15NJLH | 1 ELEMENT, 0.015 uH, CERAMIC-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| ML312RAG3N3GLP | 1 ELEMENT, 0.0033 uH, CERAMIC-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| ML312RAGR30GLC | 1 ELEMENT, 0.3 uH, CERAMIC-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| ML312RAGR33JLC | 1 ELEMENT, 0.33 uH, CERAMIC-CORE, GENERAL PURPOSE INDUCTOR, SMD |

| ML312RAG68NGLP | 1 ELEMENT, 0.068 uH, CERAMIC-CORE, GENERAL PURPOSE INDUCTOR, SMD |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| ML2375CCS | 制造商: 功能描述: 制造商:undefined 功能描述: |

| ML237B | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:6 CHANNEL TOUCH CONTROL INTERFACE |

| ML-23D-10K | 制造商:TE Connectivity 功能描述: |

| ML-23D-5K | 制造商:TE Connectivity 功能描述: |

| ML23FAD | 制造商:MTRONPTI 制造商全稱:MTRONPTI 功能描述:Micropower CMOS Oscillators |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。