- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄371126 > MMQA (ON SEMICONDUCTOR) SC-74 Quad Monolithic Common Anode PDF資料下載

參數(shù)資料

| 型號: | MMQA |

| 廠商: | ON SEMICONDUCTOR |

| 英文描述: | SC-74 Quad Monolithic Common Anode |

| 中文描述: | 資深大律師- 74四單片共陽極 |

| 文件頁數(shù): | 5/8頁 |

| 文件大?。?/td> | 104K |

| 代理商: | MMQA |

5

MOTOROLA

MMQA Series

INFORMATION FOR USING THE SC-59 6 LEAD SURFACE MOUNT PACKAGE

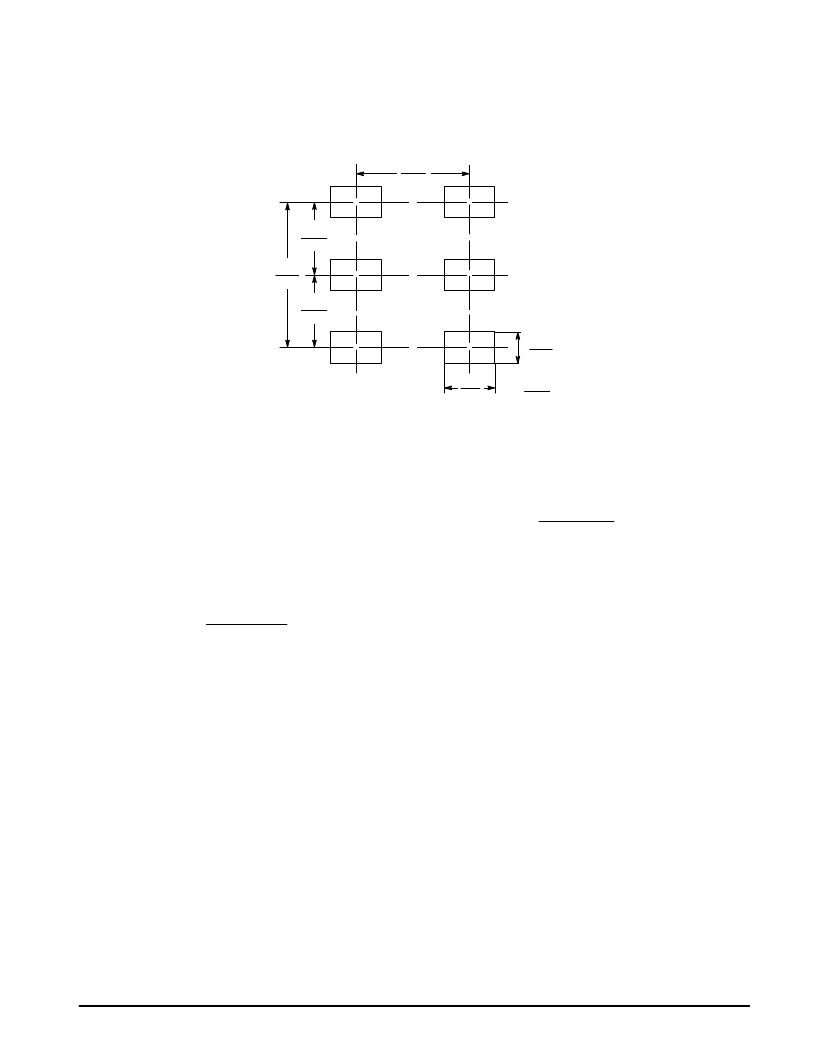

MINIMUM RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the total

design. The footprint for the semiconductor packages must

be the correct size to ensure proper solder connection inter-

face between the board and the package. With the correct

pad geometry, the packages will self-align when subjected to

a solder reflow process.

inches

mm

SC-59 6 LEAD

0.028

0.7

0.074

1.9

0.037

0.95

0.037

0.95

0.094

2.4

0.039

1.0

SC-59 6 LEAD POWER DISSIPATION

The power dissipation of the SC-59 6 Lead is a function of

the pad size. This can vary from the minimum pad size for

soldering to a pad size given for maximum power dissipation.

Power dissipation for a surface mount device is determined

by TJ(max), the maximum rated junction temperature of the

die, R

θ

JA, the thermal resistance from the device junction to

ambient, and the operating temperature, TA. Using the

values provided on the data sheet for the SC-59 6 Lead

package, PD can be calculated as follows:

TJ(max) – TA

R

θ

JA

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values into

the equation for an ambient temperature TA of 25

°

C, one can

PD =

calculate the power dissipation of the device which in this

case is 225 milliwatts.

PD =150

°

C – 25

°

C

556

°

C/W

= 225 milliwatts

The 556

°

C/W for the SC-59 6 Lead package assumes the

use of the recommended footprint on a glass epoxy printed

circuit board to achieve a power dissipation of 225 milliwatts.

There are other alternatives to achieving higher power

dissipation from the SC-59 6 Lead package. Another alterna-

tive would be to use a ceramic substrate or an aluminum

core board such as Thermal Clad

. Using a board material

such as Thermal Clad, an aluminum core board, the power

dissipation can be doubled using the same footprint.

SOLDER STENCIL GUIDELINES

Prior to placing surface mount components onto a printed

circuit board, solder paste must be applied to the pads.

Solder stencils are used to screen the optimum amount.

These stencils are typically 0.008 inches thick and may be

made of brass or stainless steel. For packages such as the

SC-59, SC-59 6 Lead, SC-70/SOT-323, SOD-123, SOT-23,

SOT-143, SOT-223, SO-8, SO-14, SO-16, and SMB/SMC

diode packages, the stencil opening should be the same as

the pad size or a 1:1 registration.

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short time could result in device failure. Therefore, the

following items should always be observed in order to mini-

mize the thermal stress to which the devices are subjected.

Always preheat the device.

The delta temperature between the preheat and

soldering should be 100

°

C or less.*

When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference should be a maximum of 10

°

C.

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MMSD1000LT1 | SWITCHING DIODE |

| MMBD1000LT1 | SWITCHING DIODE |

| MMBD3000T1 | SWITCHING DIODE |

| MMBD2000T1 | SWITCHING DIODE |

| MMSD301T1 | SOD-123 Schottky Barrier Diodes |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MMQA_05 | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:SC−74 Quad Monolithic Common Anode Transient Voltage Suppressors for ESD Protection |

| MMQA12V | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Direct ProTek Replacement:SMS08 |Alternative ProTek Replacement:PSMS12 |

| MMQA12VT | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:SC-74 Quad Monolithic Common Anode |

| MMQA12VT1 | 功能描述:TVS二極管陣列 12V 150W TVS Quad RoHS:否 制造商:Littelfuse 極性: 通道:4 Channels 擊穿電壓: 鉗位電壓:11.5 V 工作電壓:2.5 V 峰值浪涌電流:20 A 安裝風(fēng)格:SMD/SMT 端接類型:SMD/SMT 系列: 最小工作溫度:- 40 C 最大工作溫度:+ 85 C |

| MMQA12VT1G | 功能描述:TVS二極管陣列 12V 150W TVS Quad Array RoHS:否 制造商:Littelfuse 極性: 通道:4 Channels 擊穿電壓: 鉗位電壓:11.5 V 工作電壓:2.5 V 峰值浪涌電流:20 A 安裝風(fēng)格:SMD/SMT 端接類型:SMD/SMT 系列: 最小工作溫度:- 40 C 最大工作溫度:+ 85 C |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。