- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄296651 > MURHB840CTT4 (MOTOROLA INC) 4 A, 400 V, SILICON, RECTIFIER DIODE PDF資料下載

參數(shù)資料

| 型號(hào): | MURHB840CTT4 |

| 廠商: | MOTOROLA INC |

| 元件分類: | 參考電壓二極管 |

| 英文描述: | 4 A, 400 V, SILICON, RECTIFIER DIODE |

| 文件頁(yè)數(shù): | 4/6頁(yè) |

| 文件大小: | 107K |

| 代理商: | MURHB840CTT4 |

MURHB840CT

4

Rectifier Device Data

GENERAL SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

Always preheat the device.

The delta temperature between the preheat and soldering

should be 100

°C or less.*

When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference shall be a maximum of 10

°C.

The soldering temperature and time shall not exceed

260

°C for more than 5 seconds.

When shifting from preheating to soldering, the maximum

temperature gradient shall be 5

°C or less.

After soldering has been completed, the device should be

allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and result

in latent failure due to mechanical stress.

Mechanical stress or shock should not be applied during

cooling

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.

* Due to shadowing and the inability to set the wave height to

incorporate other surface mount components, the D2PAK is

not recommended for wave soldering.

RECOMMENDED PROFILE FOR REFLOW SOLDERING

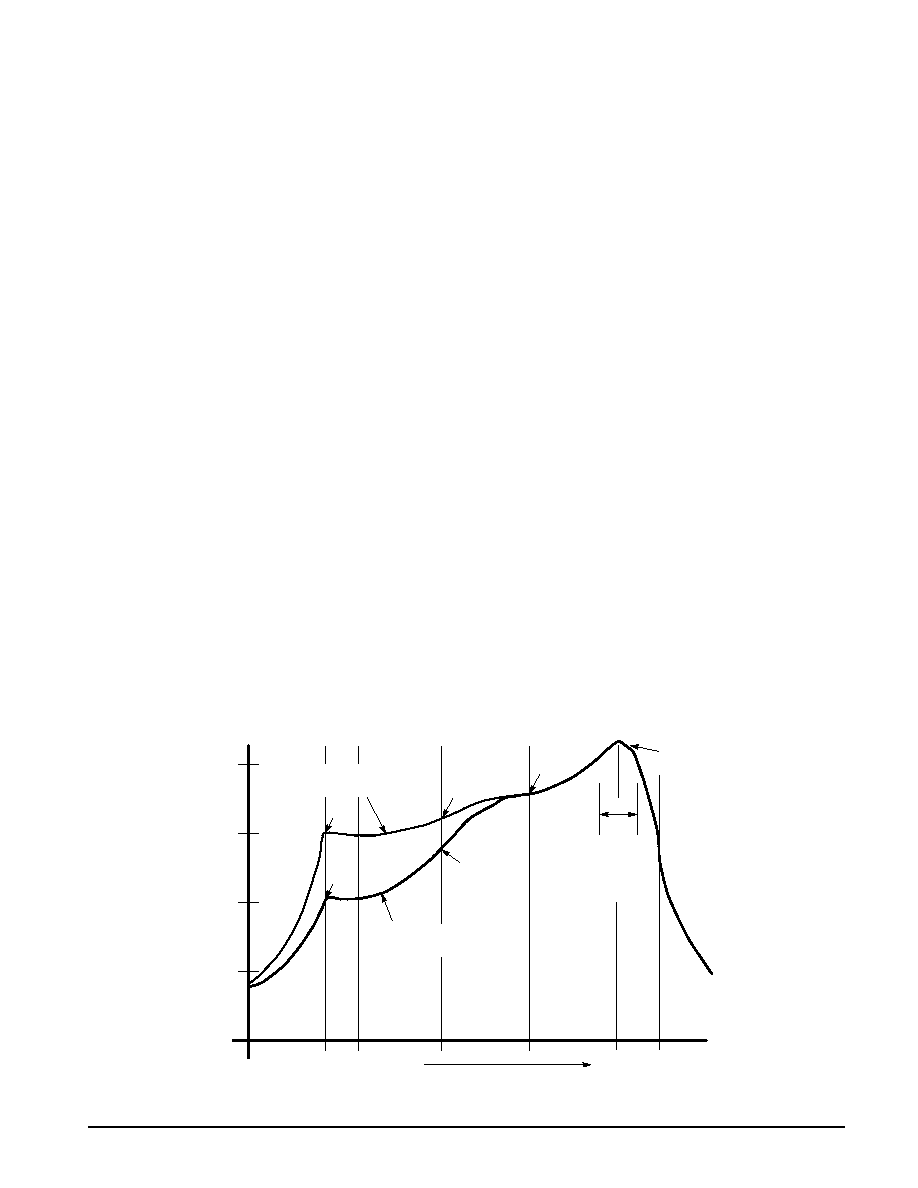

For any given circuit board, there will be a group of control

settings that will give the desired heat pattern. The operator

must set temperatures for several heating zones, and a figure

for belt speed. Taken together, these control settings make up

a heating “profile” for that particular circuit board. On

machines controlled by a computer, the computer remembers

these profiles from one operating session to the next. Figure

6 shows a typical heating profile for use when soldering the

D2PAK to a printed circuit board. This profile will vary among

soldering systems but it is a good starting point. Factors that

can affect the profile include the type of soldering system in

use, density and types of components on the board, type of

solder used, and the type of board or substrate material being

used. This profile shows temperature versus time. The line on

the graph shows the actual temperature that might be

experienced on the surface of a test board at or near a central

solder joint. The two profiles are based on a high density and

a low density board. The Vitronics SMD310 convection/in-

frared reflow soldering system was used to generate this

profile. The type of solder used was 62/36/2 Tin Lead Silver

with a melting point between 177 –189

°C. When this type of

furnace is used for solder reflow work, the circuit boards and

solder joints tend to heat first. The components on the board

are then heated by conduction. The circuit board, because it

has a large surface area, absorbs the thermal energy more

efficiently, then distributes this energy to the components.

Because of this effect, the main body of a component may be

up to 30 degrees cooler than the adjacent solder joints.

STEP 1

PREHEAT

ZONE 1

“RAMP”

STEP 2

VENT

“SOAK”

STEP 3

HEATING

ZONES 2 & 5

“RAMP”

STEP 4

HEATING

ZONES 3 & 6

“SOAK”

STEP 5

HEATING

ZONES 4 & 7

“SPIKE”

STEP 6

VENT

STEP 7

COOLING

200

°C

150

°C

100

°C

50

°C

TIME (3 TO 7 MINUTES TOTAL)

TMAX

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

205

° TO 219°C

PEAK AT

SOLDER JOINT

DESIRED CURVE FOR LOW

MASS ASSEMBLIES

DESIRED CURVE FOR HIGH

MASS ASSEMBLIES

100

°C

150

°C

160

°C

170

°C

140

°C

Figure 6. Typical Solder Heating Profile for D2PAK

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MURHB860CT | 4 A, 600 V, SILICON, RECTIFIER DIODE |

| MURS120CSM4 | 1 A, 200 V, SILICON, SIGNAL DIODE |

| MUSB-05-F-AB-SM-A-TR | 5 CONTACT(S), MALE, RIGHT ANGLE TELECOM AND DATACOM CONNECTOR, SURFACE MOUNT |

| MUSB-05-S-AB-SM-A-TR | 5 CONTACT(S), MALE, RIGHT ANGLE TELECOM AND DATACOM CONNECTOR, SURFACE MOUNT |

| MUSBMUSB-05-F-AB-SM-A | 5 CONTACT(S), FEMALE, RIGHT ANGLE TELECOM AND DATACOM CONNECTOR, SURFACE MOUNT |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MURHB840CTT4G | 功能描述:整流器 400V 8A Ultrafast RoHS:否 制造商:Vishay Semiconductors 產(chǎn)品:Standard Recovery Rectifiers 配置: 反向電壓:100 V 正向電壓下降: 恢復(fù)時(shí)間:1.2 us 正向連續(xù)電流:2 A 最大浪涌電流:35 A 反向電流 IR:5 uA 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:DO-221AC 封裝:Reel |

| MURHB860CT | 功能描述:整流器 600V 8A Ultrafast RoHS:否 制造商:Vishay Semiconductors 產(chǎn)品:Standard Recovery Rectifiers 配置: 反向電壓:100 V 正向電壓下降: 恢復(fù)時(shí)間:1.2 us 正向連續(xù)電流:2 A 最大浪涌電流:35 A 反向電流 IR:5 uA 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:DO-221AC 封裝:Reel |

| MURHB860CT/D | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:MEGAHERTZ? Power Rectifier |

| MURHB860CTG | 功能描述:整流器 600V 8A Ultrafast RoHS:否 制造商:Vishay Semiconductors 產(chǎn)品:Standard Recovery Rectifiers 配置: 反向電壓:100 V 正向電壓下降: 恢復(fù)時(shí)間:1.2 us 正向連續(xù)電流:2 A 最大浪涌電流:35 A 反向電流 IR:5 uA 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:DO-221AC 封裝:Reel |

| MURHB860CTT4 | 功能描述:整流器 600V 8A Ultrafast RoHS:否 制造商:Vishay Semiconductors 產(chǎn)品:Standard Recovery Rectifiers 配置: 反向電壓:100 V 正向電壓下降: 恢復(fù)時(shí)間:1.2 us 正向連續(xù)電流:2 A 最大浪涌電流:35 A 反向電流 IR:5 uA 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:DO-221AC 封裝:Reel |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。