- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄367632 > P03A (Electronic Theatre Controls, Inc.) POWER OPERATIONAL AMPLIFIERS PDF資料下載

參數(shù)資料

| 型號: | P03A |

| 廠商: | Electronic Theatre Controls, Inc. |

| 元件分類: | 運算放大器 |

| 英文描述: | POWER OPERATIONAL AMPLIFIERS |

| 中文描述: | 功耗運算放大器 |

| 文件頁數(shù): | 4/4頁 |

| 文件大?。?/td> | 99K |

| 代理商: | P03A |

OPERATING

CONSIDERATIONS

PA03 PA03A

GENERAL

Please read the “General Operating Considerations” section,

which covers stability, supplies, heatsinking, mounting, current

limit, SOA interpretation, and specification interpretation. Addi-

tional information can be found in the application notes. For

information on the package outline, heatsinks, and mounting

hardware, consult the “Accessory and Package Mechanical Data”

section of the handbook.

MOUNTING PRECAUTIONS

The PA03 copper base is very soft and easily bent. Do not put

any stress on the mounting ears of this package. This calls for

caution when pushing the amplifier into certain types of packaging

foam and particularly when inserting the device into a socket.

Insert the amplifier into the socket only by pushing on the perimeter

of the package lid. Pushing the unit into the socket by applying

pressure to the mounting tabs will bend the base due to the high

insertion force required. The base will then not contact the heatsink

evenly resulting in very poor heat transfer. To remove a unit from

a socket, pry the socket away from the heatsink so that the

heatsink will support the amplifier base evenly. Recommended

mounting torque is 8–10 in.-lbs. (.9–1.13 Nm).

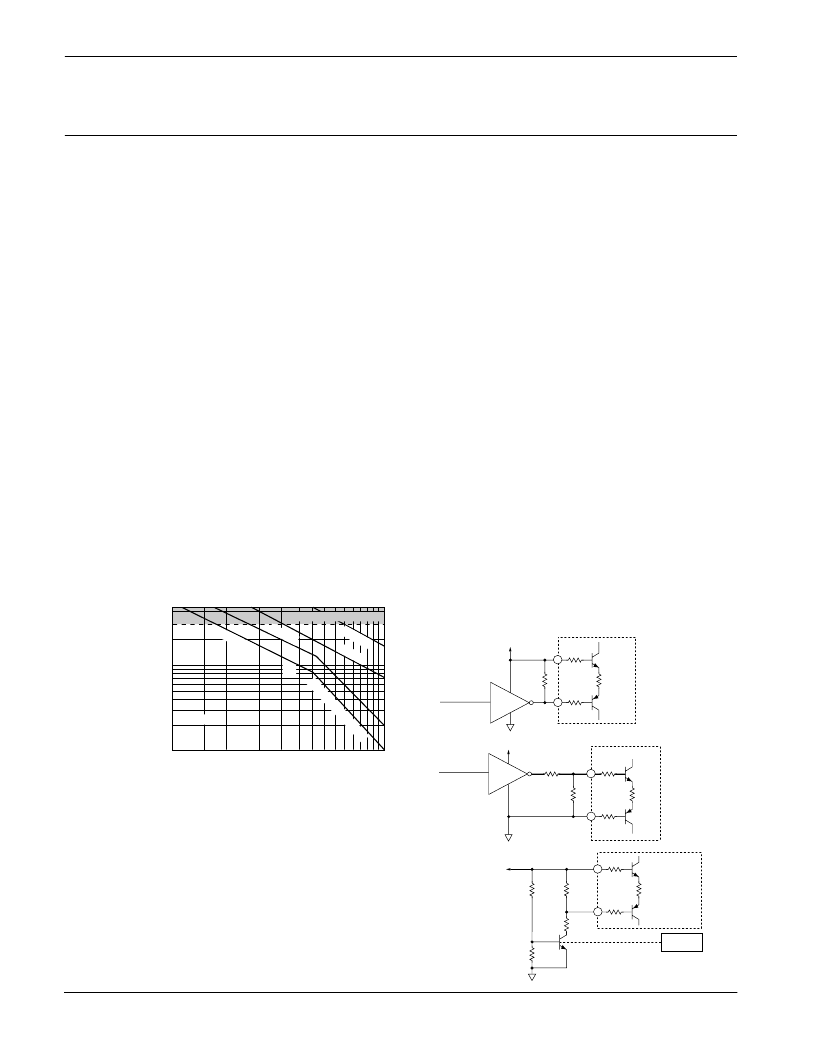

SAFE OPERATING AREA (SOA)

Due to the internal (non-adjustable) current limit of the PA03,

worst case power dissipation calculations must assume current

capability of 46 amps. Application specific circuits should be

checked against the SOA curve when relying upon current limit for

fault protectio

n.

SAFE OPERATING AREA CURVES

Second breakdown limitations do apply to the PA03 but are

less severe, since junction temperature limiting responds

within 10ms. Stress levels shown as being safe for more than

10ms duration

will

merely

cause thermal

shutdown.

Under nor-

mal operating

conditions, ac-

tivation of the

thermal shut-

down is a sign

that the inter-

nal junction

temperatures

have reached

approximately

175

°

C. Thermal shutdown is a short term safety feature. If the

conditions remain that cause thermal shutdown, the amplifier

will oscillate in and out of shutdown, creating peak high power

stresses, destroying useful signals, and reducing the reliability

of the device.

BALANCE CONTROL

The voltage offset of the PA03 may be externally adjusted to

zero. To implement this adjustment install a 100 to 200 ohm

potentiometer between pins 11 and 12 and connect the wiper arm

to the positive supply. Bypass pins 11 and 12 each with at least a

.01

μ

F ceramic capacitor.

If the optional adjust provision is not used, connect both pins 11

and 12 to the positive supply.

OUTPUT STAGE SHUTDOWN

The entire power stage of the PA03 may be disabled using one

of the circuits shown in Figure 1. There are many applications for

this function. One is a load protection based on power delivered to

the load or thermal rise. Another one is conservation of power

when using batteries. The control voltage requirements accom-

modate a wide variety logic drivers.

1. CMOS operating at +5V can drive the control pins directly.

2. CMOS operating at greater than 5V supplies need a voltage

divider.

3. TTL logic needs a pull up resistor to +5V to provide a swing to

the fully disabled voltage (3.5V). When not using the shutdown

feature, connect both pins 3 and 4 to common.

PHASE COMPENSATION

At low gain settings an external compensation capacitor is

required to insure stability. In addition to the resistive feedback

network, roll off or integrating capacitors must also be considered.

A frequency of 1 MHz is most appropriate to calculate gain.

Operation at gains below 10, without the external compensation

capacitor opens the possibility of oscillations near output satura-

tion regions when under load, the improper operation of the

thermal shutdown circuit. This can result in amplifier destruction.

At gains of 10 or more:

1. No external components are required.

2. Typical slew rate will be 8V/

μ

s.

3. Typical phase margin will be 70

°

.

At a gain of 3:

1. Connect a 470pF compensation capacitor between pins 9 and

10.

2. Typical slew rate will be 5V/

μ

s.

3. Typical phase margin will be 45

°

.

At unity gain:

1. Connect a 1.8nF compensation capacitor between pins 9 and

10.

2. Typical slew rate will be 1.8V/

μ

s.

3. Typical phase margin will be 65

°

.

1

10

20

50

100

150

5

10

30

40

SUPPLY TO OUTPUT DIFFERENTIAL V

S

–V

O

(V)

O

S

S

)

CURRENT LIMIT ZONE

100mS

10mS

10mS

THERMAL

SCONDBRADOWN

T

C

= 25°C

dc

4

3

0 = OPERATE

1 = SHUT DN

500

Q14

Q22

1K

1K

*

+5V

500

PA03

* NOT REQUIRED

CMOS LOGIC

FIGURE 1a.

DIRECT DRIVE

OF SHUTDOWN

3

0 = SHUT DN

1 = OPERATE

500

Q14

Q22

1K

R

+15V

500

PA03

FIGURE 1b.

HIGH VOLTAGE

LOGIC INTERFACE

CMOS

4

4

3

500

Q14

Q22

1K

R1

**

500

PA03

FIGURE 1c.

THERMALLY

ACTIVATED

SHUTDOWN

R2

LOAD

R4

36R3

360–

THERMAL SENSE

TRANSISTOR

+V

S

2R

** SELECT SHUTOFF

TEMPERATURE

DROP ON R2

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

PA03U REV. I FEBRUARY 1998

1998 Apex Microtechnology Corp.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| P03B | 3 Lead Molded TO-202 NS Package Number P03B |

| P0402FC05C | Direct ProTek Replacement:P0402FC05C |

| P0402FC08C | Direct ProTek Replacement:P0402FC08C |

| P0402FC12C | Direct ProTek Replacement:P0402FC12C |

| P0402FC15C | Direct ProTek Replacement:P0402FC15C |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| P03B | 制造商:NSC 制造商全稱:National Semiconductor 功能描述:3 Lead Molded TO-202 NS Package Number P03B |

| P03CG0R82C500NT | 制造商: 功能描述: 制造商:undefined 功能描述: |

| P03E/4BC800 EVOLTA | 制造商:Panasonic 功能描述:Pack |

| P03I/2BC800 | 制造商:Panasonic Industrial Company 功能描述:Battery NiMH Infinium Micro AAA 780mAh |

| P03N60 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:P03N60 TO-220 Small Signal MOSFET |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。