- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄367634 > P0770 POWER MAGNETICS CATALOG (68 pages) - (5/02) PDF資料下載

參數(shù)資料

| 型號: | P0770 |

| 英文描述: | POWER MAGNETICS CATALOG (68 pages) - (5/02) |

| 中文描述: | 功率磁性元件產(chǎn)品目錄(68頁) - (5 / 02) |

| 文件頁數(shù): | 15/68頁 |

| 文件大小: | 2741K |

| 代理商: | P0770 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁當前第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁

13

PC500.B (5/02)

US 858 674 8100

UK 44 1483 401 700

France 33 3 84 35 04 04

Singapore 65 287 8998

Taiwan 886 2 2698 0228

Hong Kong 852 2788 6588

http://www.pulseeng.com

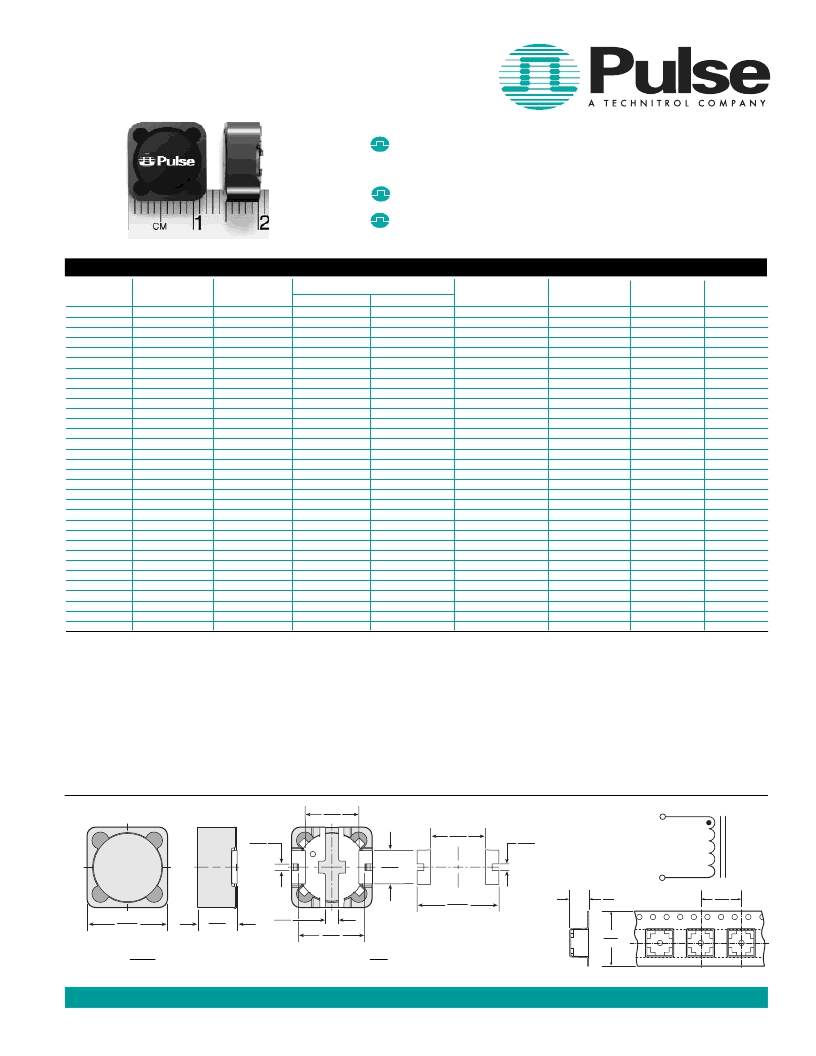

SMT POWER INDUCTORS

Shielded Drum Core - P1170 Series

Low profile and suitable for compact surface

area mounting

Large permissible DC current

Low DC resistance

Mechanical

Schematic

Weight

. . . . . . . . 3.2 grams

Tape & Reel

. . . . . . 500/reel

Unless otherwise specified, all tolerances are ±0,25

Dimensions:

Inches

mm

Part

Number

P1170.901T

P1170.142T

P1170.222T

P1170.302T

P1170.392T

P1170.502T

P1170.642T

P1170.103T

P1170.123T

P1170.153T

P1170.183T

P1170.223T

P1170.273T

P1170.333T

P1170.393T

P1170.473T

P1170.563T

P1170.683T

P1170.823T

P1170.104T

P1170.124T

P1170.154T

P1170.184T

P1170.224T

P1170.274T

P1170.334T

P1170.394T

P1170.474T

P1170.564T

P1170.684T

P1170.824T

P1170.105T

Notes from Table

1. The rated current as listed is either the saturation current

or the heating current depending on which value is lower.

Inductance

@Irated

(

μ

H) MIN

0.6

0.9

1.5

2.0

2.5

3.3

4.2

7.5

9.0

11.3

13.5

16.5

20.3

24.8

29.3

35.3

42.0

51.0

61.5

75.0

90.0

113

135

165

203

248

293

353

420

510

615

750

Irated

1

(A

DC

)

13

11

9.6

8.3

7.0

6.4

5.3

4.4

4.2

4.0

3.4

3.0

2.7

2.6

2.4

2.2

2.0

1.8

1.7

1.4

1.3

1.2

1.1

1.0

0.91

0.82

0.72

0.68

0.63

0.57

0.52

0.46

DCR (m

)

Inductance

@0A

DC

(

μ

H)

0.9±30%

1.4±30%

2.2±30%

3.0±30%

3.9±30%

5.0±30%

6.4±30%

10±20%

12±20%

15±20%

18±20%

22±20%

27±20%

33±20%

39±20%

47±20%

56±20%

68±20%

82±20%

100±20%

120±20%

150±20%

180±20%

220±20%

270±20%

330±20%

390±20%

470±20%

560±20%

680±20%

820±20%

1000±20%

Saturation

Current

@25°C (A)

14

13

9.7

8.3

7.0

6.4

5.8

4.6

4.3

4.0

3.4

3.0

2.7

2.6

2.4

2.2

2.0

1.8

1.7

1.4

1.3

1.2

1.1

1.0

0.91

0.82

0.72

0.68

0.63

0.57

0.52

0.46

2

Heating

Current

(A)

13

11

9.6

8.3

7.1

6.6

5.3

4.4

4.2

4.1

3.4

3.2

3.0

2.6

2.5

2.2

2.1

1.9

1.7

1.4

1.4

1.3

1.2

1.1

1.0

0.93

0.81

0.77

0.66

0.62

0.54

0.51

3

Core Loss

4

Factor K

136.3

165.0

212.1

244.7

275.7

311.9

357.2

424.2

471.3

548.5

578.4

666.6

734.2

813.8

879.9

977.3

1041.8

1144.6

1260.2

1413.9

1533.2

1710.4

1889.9

2101.8

2327.8

2554.4

2775.7

3057.7

3317.6

3660.4

4007.2

4437.0

TYP

2.0

3.0

4.0

5.4

7.4

8.5

13

19

21

22

32

36

41

56

60

79

85

97

127

182

201

225

249

319

363

424

561

629

851

950

1241

1398

MAX

2.9

4.2

5.7

7.7

10

12

18

25

27

30

40

45

51

70

75

100

110

120

158

230

253

280

310

400

460

530

690

770

1060

1200

1550

1750

2. The saturation current is the current which causes the

inductance to drop to 65% (or 75%) of its nominal induc-

tance at zero bias. This current is determined by placing

the component at room ambient (25°C), and applying a

short duration pulse current (to eliminate self-heating

effects) to the component.

3. The heating current is the dc current, which causes the

temperature of the part to increase by not more than 40°C.

This current is determined by extending the terminals of the

component with 30mm length 28 gauge buss wires and

applying the current to the device for 30 minutes. The tem-

perature is measured by placing the thermocouple between

the winding and the shield.

4. In high volt*time applications, additional heating in the

component can occur due to core losses in the inductor

which may necessitate derating the current in order to limit

the temperature rise of the component. In order to deter-

mine the approximate total loss (or temperature rise) for a

given application, both copper losses and core losses

should be taken into account.

Estimated Temperature Rise:

Trise = [Total loss (mW) / 5.376]

.833

(

o

C )

Total loss = Copper loss + Core loss (mW)

Copper loss = Irms

2

x DCR (Typical) (mW)

Irms = [I

DC

2

+

I

2

/12]

1/2

(A)

Core loss = 2.92 x 10

-7

x f (kHz)

1.1

x (K x

I)

2.15

(mW),

where f varies between 25 kHz and 300 kHZ, and B less

than 2000 Gauss.

Electrical Specifications @ 25°C — Operating Temperature -40°C to +85°C

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| P07D03LVG | Dual N-Channel Enhancement Mode Field Effect Transistor |

| P07D03LV | Circular Connector; MIL SPEC:MIL-C-26482, Series I, Solder; Body Material:Aluminum; Series:PT08; No. of Contacts:12; Connector Shell Size:14; Connecting Termination:Solder; Circular Shell Style:Right Angle Plug |

| P0808ATG | N-Channel Enhancement Mode Field Effect Transistor |

| P0903BDG | N-Channel Logic Level Enhancement Mode Field Effect Transistor |

| P0903BI | N-Channel Logic Level Enhancement Mode Field Effect Transistor |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| P0770.102NL | 功能描述:1μH Unshielded Wirewound Inductor 2.9A 50 mOhm Max Nonstandard 制造商:pulse electronics corporation 系列:P0770NL 包裝:托盤 零件狀態(tài):有效 類型:繞線 材料 - 磁芯:- 電感:1μH 容差:±20% 額定電流:2.9A 電流 - 飽和值:2.9A 屏蔽:無屏蔽 DC 電阻(DCR):50 毫歐最大 不同頻率時的 Q 值:- 頻率 - 自諧振:- 等級:- 工作溫度:-40°C ~ 130°C 頻率 - 測試:100kHz 安裝類型:表面貼裝 封裝/外殼:非標準 大小/尺寸:0.260" 長 x 0.175" 寬(6.60mm x 4.45mm) 高度 - 安裝(最大值):0.115"(2.92mm) 標準包裝:145 |

| P0770.102NLT | 功能描述:固定電感器 1.0uH 20% ’102’ RoHS:否 制造商:AVX 電感:10 uH 容差:20 % 最大直流電流:1 A 最大直流電阻:0.075 Ohms 工作溫度范圍:- 40 C to + 85 C 自諧振頻率:38 MHz Q 最小值:40 尺寸:4.45 mm W x 6.6 mm L x 2.92 mm H 屏蔽:Shielded 端接類型:SMD/SMT 封裝 / 箱體:6.6 mm x 4.45 mm |

| P0770.102T | 制造商:Pulse 功能描述:IND PWR UNSHLD 1UH 20% 100KHZ 2.9A - Tape and Reel 制造商:Pulse Electronics Corporation 功能描述:Ind Power Unshielded Wirewound 1uH 20% 100KHz 2.9A T/R |

| P0770.103 | 制造商:Pulse 功能描述:- Bulk |

| P0770.103NL | 制造商:Pulse 功能描述:- Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。