- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄368107 > PR02-220K WIDERSTAND LEISTUNG METALL 220K 500V 2W PDF資料下載

參數(shù)資料

| 型號(hào): | PR02-220K |

| 英文描述: | WIDERSTAND LEISTUNG METALL 220K 500V 2W |

| 中文描述: | WIDERSTAND給付220,000 500V 2W的金屬 |

| 文件頁(yè)數(shù): | 2/24頁(yè) |

| 文件大小: | 591K |

| 代理商: | PR02-220K |

第1頁(yè)當(dāng)前第2頁(yè)第3頁(yè)第4頁(yè)第5頁(yè)第6頁(yè)第7頁(yè)第8頁(yè)第9頁(yè)第10頁(yè)第11頁(yè)第12頁(yè)第13頁(yè)第14頁(yè)第15頁(yè)第16頁(yè)第17頁(yè)第18頁(yè)第19頁(yè)第20頁(yè)第21頁(yè)第22頁(yè)第23頁(yè)第24頁(yè)

2001 Jul 13

2

BCcomponents

Product specification

Professional power metal film resistors

PR01/02/03

FEATURES

High power in small packages

Different lead materials for different

applications

Defined interruption behaviour.

APPLICATIONS

All general purpose power

applications.

DESCRIPTION

A homogeneous film of metal alloy is

deposited on a high grade ceramic

body. After a helical groove has been

cut in the resistive layer, tinned

connecting wires of electrolytic copper

or copper-clad iron are welded to the

end-caps. The resistors are coated with

a red, nonflammable lacquer which

provides electrical, mechanical and

climatic protection. This coating is not

resistant to aggressive fluxes. The

encapsulation is resistant to all

cleaning solvents in accordance with

“MIL-STD-202E, method 215”

, and

“IEC 60068-2-45”

.

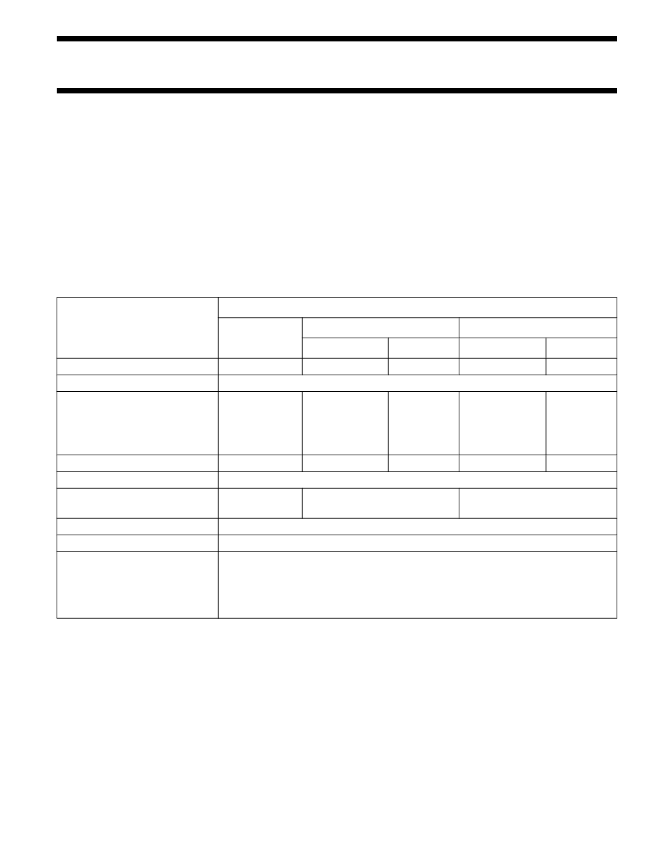

QUICK REFERENCE DATA

Notes

1.

2.

1% tolerance is available for R

n

-range from 1R upwards.

2% tolerance is available on request for R

n

-range from 1R upwards.

DESCRIPTION

VALUE

PR01

PR02

PR03

Cu-lead

FeCu-lead

1

to 1 M

Cu-lead

0.68

to 1 M

FeCu-lead

1

to 1 M

Resistance range

Resistance tolerance and series

Maximum dissipation at

T

amb

= 70

°

C:

R < 1

1

≤

R

Thermal resistance (R

th

)

Temperature coefficient

Maximum permissible voltage

(DC or RMS)

Basic specifications

Climatic category (IEC 60068)

Stability after:

load

climatic tests

soldering

0.22

to 1 M

0.33

to 1 M

±

1% (E24, E96 series);

±

5% (E24 series); see notes 1 and 2

0.6 W

1 W

135 K/W

1.2 W

2 W

75 K/W

1.6 W

3 W

60 K/W

1.3 W

115 K/W

2.5 W

75 K/W

≤±

250

×

10

6

/K

350 V

500 V

750 V

IEC 60115-1 and 60115-4

55/155/56

R/R max.:

±

5% + 0.1

R/R max.:

±

3% + 0.1

R/R max.:

±

1% + 0.05

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| PR02-220R | WIDERSTAND LEISTUNG METALL 220R 500V 2W |

| PR02-22K | WIDERSTAND LEISTUNG METALL 22K 500V 2W |

| PR02-330K | WIDERSTAND LEISTUNG METALL 330K 500V 2W |

| PR1001 | 1 AMP FAST RECOVERY RECTIFIER |

| PR1001 | 1.0A FAST RECOVERY RECTIFIER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| PR02-220R | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:WIDERSTAND LEISTUNG METALL 220R 500V 2W |

| PR02-22K | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:WIDERSTAND LEISTUNG METALL 22K 500V 2W |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。