- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄373260 > REG113-285 DMOS 400mA Low-Dropout Regulator PDF資料下載

參數(shù)資料

| 型號(hào): | REG113-285 |

| 英文描述: | DMOS 400mA Low-Dropout Regulator |

| 中文描述: | 的DMOS 400mA的低壓差穩(wěn)壓器 |

| 文件頁數(shù): | 8/12頁 |

| 文件大小: | 382K |

| 代理商: | REG113-285 |

REG1117, REG1117A

SBVS001B

8

www.ti.com

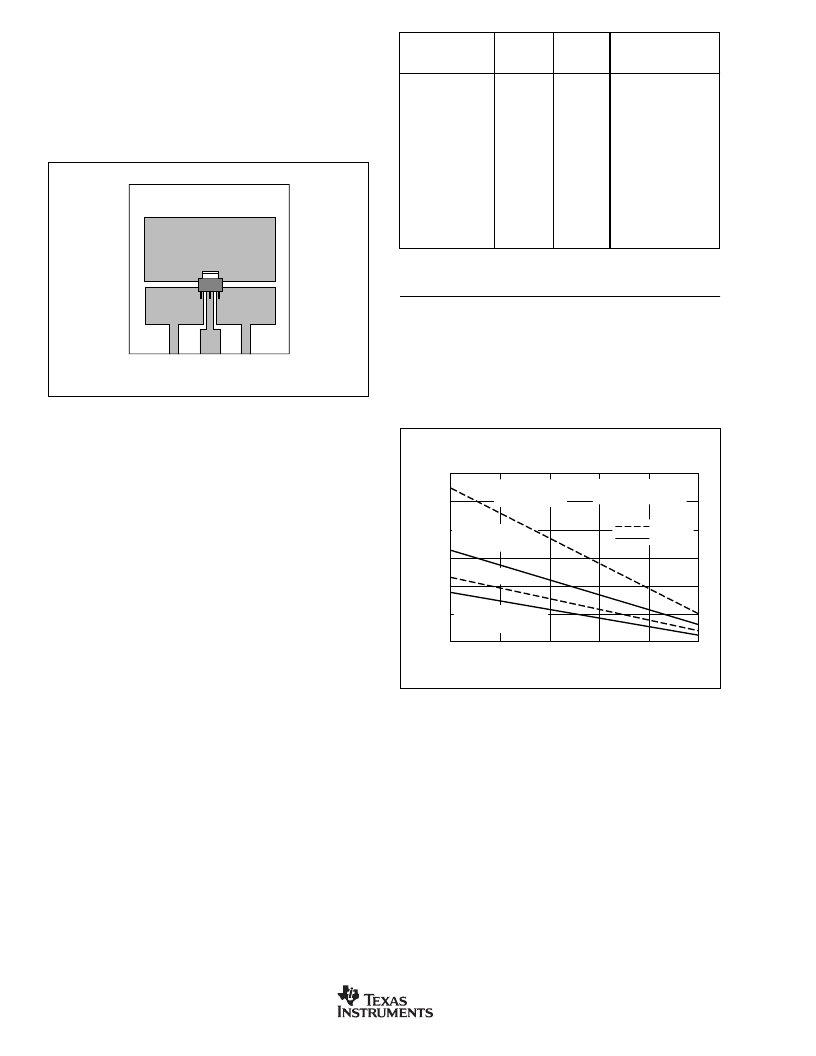

The SOT-223 package derives heat sinking from conduction

through its copper leads, especially the large mounting tab.

These must be soldered to a circuit board with a substantial

amount of copper remaining, as shown in Figure 5. Circuit

board traces connecting the tab and the leads should be made

as large as practical. The mounting tab of both packages is

electrically connected to V

OUT

.

Without back-side copper:

θ

JA

≈

59

°

C/W

With solid back-side copper:

θ

JA

≈

49

°

C/W

FIGURE 5. SOT-223 Circuit Board Layout Example.

Other nearby circuit traces, including those on the back side

of the circuit board, help conduct heat away from the device,

even though they may not be electrically connected. Make

all nearby copper traces as wide as possible and leave only

narrow gaps between traces.

Table I shows approximate values of

θ

JA

for various circuit

board and copper areas for the SOT-223 package. Nearby

heat dissipating components, circuit board mounting condi-

tions, and ventilation can dramatically affect the actual

θ

JA

.

Proper heat sinking significantly increases the maximum

power dissipation at a given ambient temperature, as shown

in Figure 6.

SOLDERING METHODS

Both REG1117 packages are suitable for infrared reflow and

vapor-phase reflow soldering techniques. The high rate of

temperature change that occurs with wave soldering, or hand

soldering can damage the REG1117.

TOPSIDE

(1)

COPPER

AREA

BACKSIDE

COPPER

AREA

SOT-223

TOTAL PC BOARD

AREA

THERMAL RESISTANCE

JUNCTION-TO-AMBIENT

46

°

C/W

47

°

C/W

49

°

C/W

51

°

C/W

53

°

C/W

55

°

C/W

58

°

C/W

59

°

C/W

67

°

C/W

72

°

C/W

85

°

C/W

2500mm

2

2500mm

2

2500mm

2

2500mm

2

1250mm

2

2500mm

2

2500mm

2

950mm

2

2500mm

2

2500mm

2

2500mm

2

0

2500mm

2

1800mm

2

0

1600mm

2

600mm

2

1600mm

2

2500mm

2

1250mm

2

0

2500mm

2

915mm

2

0

1600mm

2

600mm

2

0

900mm

2

340mm

2

900mm

2

900mm

2

340mm

2

0

NOTE: (1) Tab is attached to the topside copper.

TABLE I.

INSPEC Abstract Number: B91007604, C91012627

Kelly, E.G. “Thermal Characteristics of Surface 5WK9

Packages.” The Proceedings of SMTCON. Surface Mount

Technology Conference and Exposition:

Competitive Surface

Mount Technology

, April 3-6, 1990, Atlantic City, NJ, USA.

Abstract Publisher

: IC Manage, 1990, Chicago, IL, USA.

FIGURE 6. Maximum Power Dissipation versus Ambient

Temperature.

Total Area: 50 x 50mm

35 x 17 mm

16 x 10 mm

16 x 10 mm

6

5

4

3

2

1

0

P

0

25

50

75

100

125

Ambient Temperature (

°

C)

MAXIMUM POWER DISSIPATION

vs AMBIENT TEMPERATURE

P

D

= (T

(max)

–

T

A

)

/

JA

T

J

(max) = 150

°

C

θ

DDPAK

SOT-223

= 85

°

C/W

(340mm

2

topside copper,

no backside copper)

θ

= 46

°

C/W

(2500mm

2

topside and

backside copper)

θ

= 27

°

C/W

(4in

one oz copper

mounting pad)

θ

θ

= 65

°

C/W

(no heat sink)

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| REG113-3 | DMOS 400mA Low-Dropout Regulator |

| REG113-33 | DMOS 400mA Low-Dropout Regulator |

| REG113-5 | DMOS 400mA Low-Dropout Regulator |

| REG1117FA-5 | THREE-TERMINAL POSITIVE FIXED VOLTAGE REGULATORS |

| REG1117FA-TR | Positive Adjustable Voltage Regulator |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| REG113-3 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:DMOS 400mA Low-Dropout Regulator |

| REG113-33 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:DMOS 400mA Low-Dropout Regulator |

| REG113-5 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:DMOS 400mA Low-Dropout Regulator |

| REG113EA-2.5/250 | 功能描述:低壓差穩(wěn)壓器 - LDO DMOS 400mA Regulator Low-Dropout RoHS:否 制造商:Texas Instruments 最大輸入電壓:36 V 輸出電壓:1.4 V to 20.5 V 回動(dòng)電壓(最大值):307 mV 輸出電流:1 A 負(fù)載調(diào)節(jié):0.3 % 輸出端數(shù)量: 輸出類型:Fixed 最大工作溫度:+ 125 C 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:VQFN-20 |

| REG113EA-2.5/250G4 | 功能描述:低壓差穩(wěn)壓器 - LDO DMOS 400mA Regulator Low-Dropout RoHS:否 制造商:Texas Instruments 最大輸入電壓:36 V 輸出電壓:1.4 V to 20.5 V 回動(dòng)電壓(最大值):307 mV 輸出電流:1 A 負(fù)載調(diào)節(jié):0.3 % 輸出端數(shù)量: 輸出類型:Fixed 最大工作溫度:+ 125 C 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:VQFN-20 |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。