- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄385770 > RF3404 (RF MICRO DEVICES INC) DUAL-BAND/TRI-MODE CDMA LOW NOISE AMPLIFIER/MIXER MODULE PDF資料下載

參數(shù)資料

| 型號(hào): | RF3404 |

| 廠商: | RF MICRO DEVICES INC |

| 元件分類: | 無繩電話/電話 |

| 英文描述: | DUAL-BAND/TRI-MODE CDMA LOW NOISE AMPLIFIER/MIXER MODULE |

| 中文描述: | TELECOM, CELLULAR, RF AND BASEBAND CIRCUIT, PBGA48 |

| 封裝: | 8 X 8 MM, MODULE, LGA-48 |

| 文件頁數(shù): | 10/12頁 |

| 文件大小: | 202K |

| 代理商: | RF3404 |

Preliminary

8-42

RF3404

Rev A1 010918

8

F

traces required to converge on the perimeter of the

module. Routing is eased by viaholes that can be

placed between the inner row of connections and the

center ground pad in the cellular/PCS telephone PCB.

Why Use Integrated Modules

Decreased Board Area

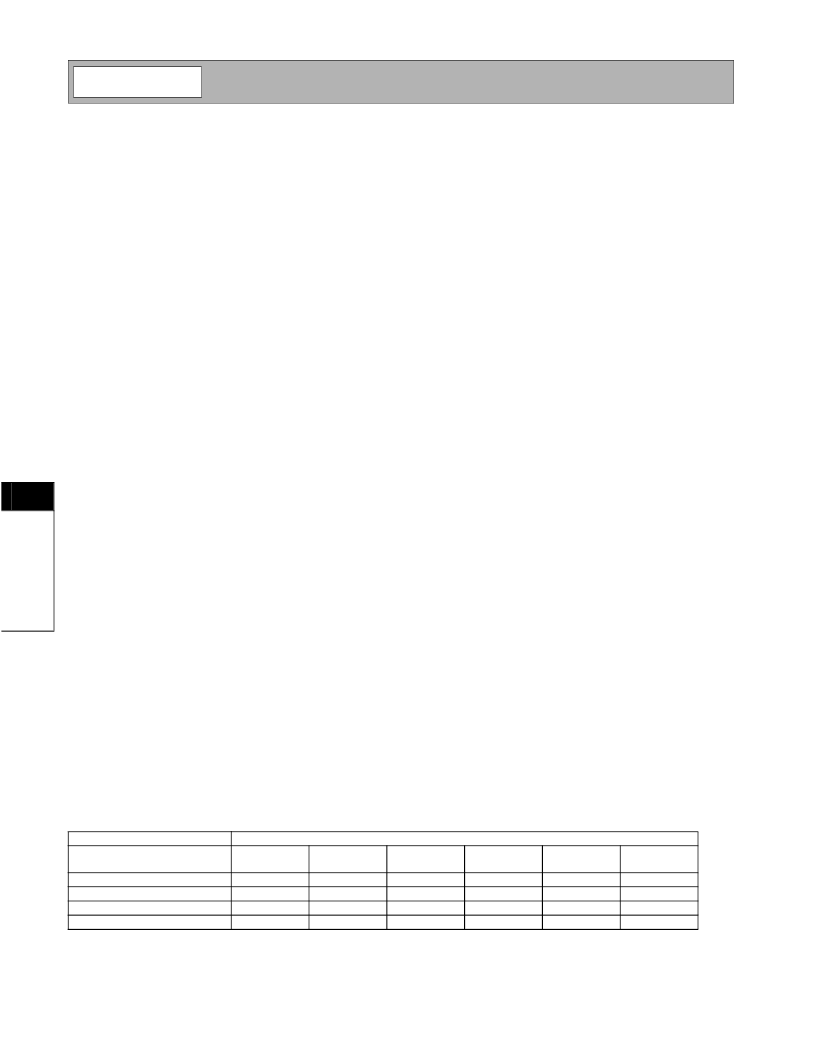

Table A shows a comparison between the leading four

design approaches for dual-band/tri-mode CDMA front

ends:

1. discrete LNAs and discrete mixers with off-chip

matching for each component,

2. single band cellular and PCS LNA/Mixer MMICs

with off-chip matching,

3. single MMIC dual band chips with off-chip matching

and finally

4. fully integrated modules like the RF3404.

Table A summarizes the number of SMD components

for each approach as well as the typical amount of

phone board space required for a complete layout.The

RF3404 represents a 50 percent to 70 percent reduc-

tion in the amount of board space required when com-

pared with the most highly integrated chip solutions on

the market today. Furthermore, it represents the larg-

est percentage improvement in board space savings

for any of the other increased integration gains in

recent years.

Reduced BOM Counts

Another area where one can see marked improvement

is in BOM reduction. The RF3404 reduces the BOM

from the most highly integrated alternatives available

today that contain approximately 25 components to

only three. The three are VCC-bypassing capacitors

that depend on the frequency response of the phone

board power supply and a resistor.

Simplify the Supply Chain

The supply chain can be significantly simplified with

the elimination of two dozen components that would

not need to be source selected, qualified, purchased,

received, stored, coordinated or delivered to the fac-

tory floor.

Decreased Engineering and Product Cycle Time

With a single module solution the RF engineering

required to design the front end is significantly

reduced. The RF3404 module allows for a design-in

solution meeting all of the IS95B requirements, which

requires significantly less engineering.

Decreased Assembly Costs

Accordingly, assembly costs are also reduced. With

SMD placement costs running in the range of 1.0cents

to 1.3cents per placement and with the placement of

die packages, SAWs, and modules costing even more

per placement, one can eliminate somewhere around

35cents from the cost of assembly with modules and

improve factory throughput.

Improve Phone Level Yield

Known good RF performance at the module level is

available with integrated modules that have been RF

tested. Phone level yield can be improved, in addition

to the improvement in yield from placing two dozen

fewer components.

Improved Reliability

Mechanical attachment and reliability is improved with

this module technology due to a variety of factors. The

first is the elimination of numerous components and

thus solder joints, which directly aids overall phone reli-

ability. Another important factor is the matched coeffi-

cient of thermal expansion (CTE) between the laminate

module and the cellular/PCS telephone PCB that elimi-

nates much of the solder stress potential found in low-

temperature-cofired-ceramic

modules and should provide the most robust solution

for the stringent mechanical shock and drop tests that

mobile telephone hardware must survive.

(LTCC)

or

chip-scale

Table A. Comparison of Alternate CDMA Front-End Solution Approaches

Number of Components*

Inductors

Level of Integration

Caps

Resistors

Saws

Total

Components

3

24

35

40

Board Area

(sq. mm)

67

~200

~280

~350

RF3404 Module

Dual Band Integrated MMIC

Single Band Integrated MMIC

LNA/Mixer Discrete Solution

*Does not include IF matching components to IF SAW filters.

2

4

8

8

0

7

6

6

0

2

2

2

11

19

24

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| RF3404PCBA | DUAL-BAND/TRI-MODE CDMA LOW NOISE AMPLIFIER/MIXER MODULE |

| RF3800 | GaAs HBT PRE-DRIVER AMPLIFIER |

| RF3800PCBA-416 | GaAs HBT PRE-DRIVER AMPLIFIER |

| RF3802 | GaAs HBT PRE-DRIVER AMPLIFIER |

| RF3802PCBA-410 | GaAs HBT PRE-DRIVER AMPLIFIER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| RF3404D | 功能描述:信號(hào)調(diào)節(jié) 433.92MHz Narrowband Receiver Front End RoHS:否 制造商:EPCOS 產(chǎn)品:Duplexers 頻率:782 MHz, 751 MHz 頻率范圍: 電壓額定值: 帶寬: 阻抗:50 Ohms 端接類型:SMD/SMT 封裝 / 箱體:2.5 mm x 2 mm 工作溫度范圍:- 30 C to + 85 C 封裝:Reel |

| RF3404E | 功能描述:信號(hào)調(diào)節(jié) 433.92MHz Narrowband Receiver Front End RoHS:否 制造商:EPCOS 產(chǎn)品:Duplexers 頻率:782 MHz, 751 MHz 頻率范圍: 電壓額定值: 帶寬: 阻抗:50 Ohms 端接類型:SMD/SMT 封裝 / 箱體:2.5 mm x 2 mm 工作溫度范圍:- 30 C to + 85 C 封裝:Reel |

| RF3404PCBA | 制造商:RFMD 制造商全稱:RF Micro Devices 功能描述:DUAL-BAND/TRI-MODE CDMA LOW NOISE AMPLIFIER/MIXER MODULE |

| RF341-12 | 制造商:Teledyne Relays 功能描述:RELAY - Bulk |

| RF341-26 | 制造商:TELEDYNE 制造商全稱:TELEDYNE 功能描述:ULTRAMINIATURE MAGNETIC LATCHING TO-5 RELAYS SPDT DC TO C BAND |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。