- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄98220 > THS3091DDAR (TEXAS INSTRUMENTS INC) 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 PDF資料下載

參數(shù)資料

| 型號: | THS3091DDAR |

| 廠商: | TEXAS INSTRUMENTS INC |

| 元件分類: | 音頻/視頻放大 |

| 英文描述: | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| 封裝: | GREEN, PLASTIC, SOP-8 |

| 文件頁數(shù): | 16/37頁 |

| 文件大?。?/td> | 1078K |

| 代理商: | THS3091DDAR |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁當前第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁

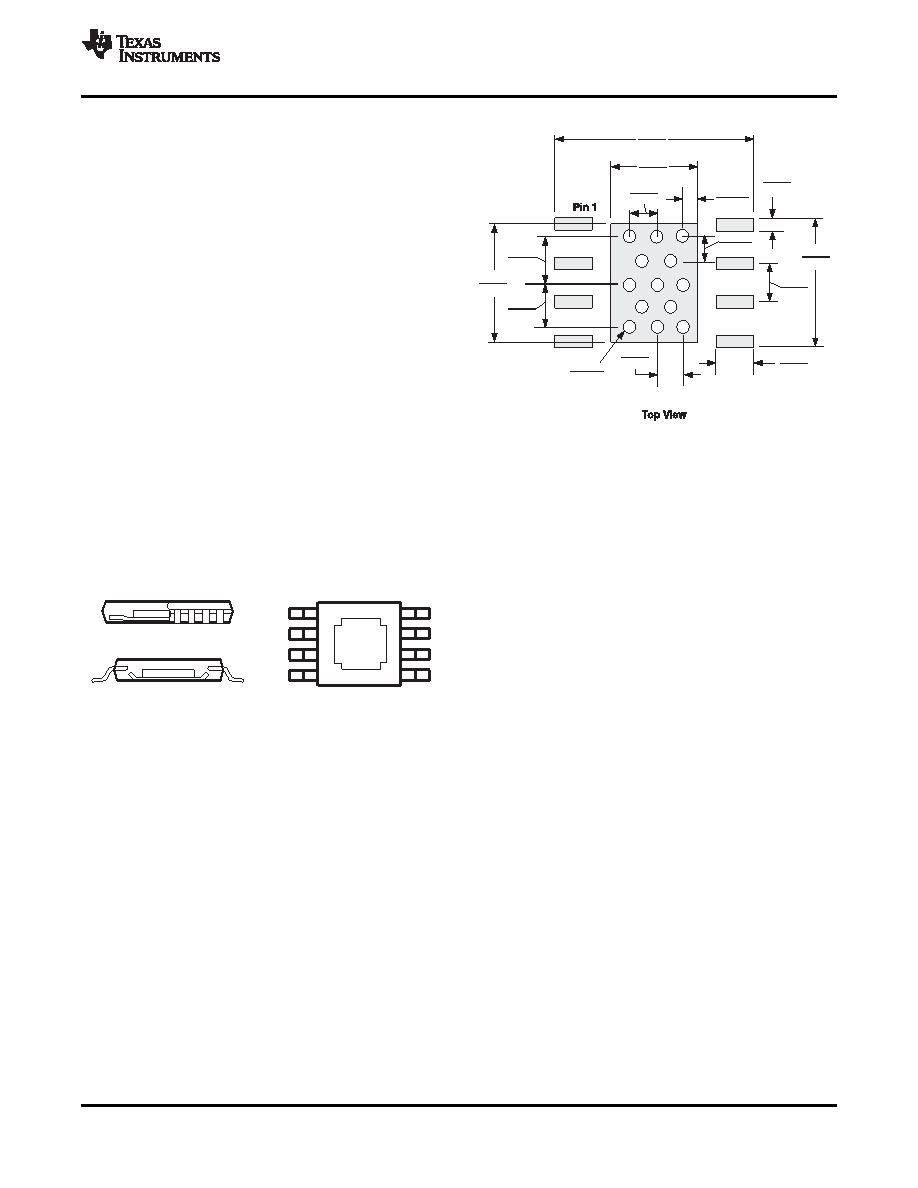

PowerPAD DESIGN CONSIDERATIONS

0.300

(7,62)

0.100

(2,54)

0.035

(0,89)

0.010

(0,254)

0.030

(0,732)

0.026

(0,66)

0.176

(4,47)

0.050

(1,27)

0.080

(2,03)

0.035

(0,89)

0.010

vias

(0.254)

0.140

(3,56)

0.060

(1,52)

0.060

(1,52)

AllUnitsininches(millimeters)

PowerPAD LAYOUT CONSIDERATIONS

DIE

Side View (a)

DIE

End View (b)

Thermal

Pad

Bottom View (c)

www.ti.com........................................................................................................................................ SLOS423G – SEPTEMBER 2003 – REVISED OCTOBER 2008

The

THS3091/5

are

available

in

a

thermally-enhanced PowerPAD family of packages.

These packages are constructed using a downset

leadframe

on

which

the

die

is

mounted

[see

Figure 71(a) and Figure 71(b)]. This arrangement

results in the lead frame being exposed as a thermal

pad

on

the

underside

of

the

package

[see

Figure 71(c)]. Because this thermal pad has direct

thermal contact with the die, excellent thermal

performance can be achieved by providing a good

thermal path away from the thermal pad. Note that

devices such as the THS3091/5 have no electrical

connection between the PowerPAD and the die.

The PowerPAD package allows for both assembly

and thermal management in one manufacturing

operation. During the surface-mount solder operation

(when the leads are being soldered), the thermal pad

can also be soldered to a copper area underneath the

Figure 72. DDA PowerPAD PCB Etch and Via

package. Through the use of thermal paths within this

Pattern

copper area, heat can be conducted away from the

package

into

either

a

ground

plane

or

other

heat-dissipating device.

1. PCB with a top-side etch pattern is shown in

The PowerPAD package represents a breakthrough

Figure 72. There should be etch for the leads as

in combining the small area and ease of assembly of

well as etch for the thermal pad.

surface

mount

with

the,

heretofore,

awkward

mechanical methods of heatsinking.

2. Place 13 holes in the area of the thermal pad.

These holes should be 0.01 inch (0,254 mm) in

diameter. Keep them small so that solder wicking

through the holes is not a problem during reflow.

3. Additional vias may be placed anywhere along

the thermal plane outside of the thermal pad

area. This helps dissipate the heat generated by

the THS3091/5 IC. These additional vias may be

larger than the 0.01-inch (0,254 mm) diameter

Figure 71. Views of Thermal Enhanced Package

vias directly under the thermal pad. They can be

larger because they are not in the thermal pad

area to be soldered so that wicking is not a

Although there are many ways to properly heatsink

problem.

the PowerPAD package, the following steps illustrate

the recommended approach.

4. Connect all holes to the internal ground plane.

Note that the PowerPAD is electrically isolated

from the silicon and all leads. Connecting the

PowerPAD to any potential voltage such as VS– is

acceptable as there is no electrical connection to

the silicon.

5. When connecting these holes to the ground

plane, do not use the typical web or spoke via

connection methodology. Web connections have

a high thermal resistance connection that is

useful for slowing the heat transfer during

soldering operations. This makes the soldering of

vias that have plane connections easier. In this

application, however, low thermal resistance is

desired for the most efficient heat transfer.

Therefore,

the

holes

under

the

THS3091/5

PowerPAD

package

should

make

their

connection to the internal ground plane with a

Copyright 2003–2008, Texas Instruments Incorporated

23

相關PDF資料 |

PDF描述 |

|---|---|

| THS3091DDA | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS3091DR | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS3091D | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS3091DRG4 | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS3091DG4 | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| THS3091DDARG3 | 功能描述:高速運算放大器 Single Lo-Distort Current Feedback RoHS:否 制造商:Texas Instruments 通道數(shù)量:1 電壓增益 dB:116 dB 輸入補償電壓:0.5 mV 轉(zhuǎn)換速度:55 V/us 工作電源電壓:36 V 電源電流:7.5 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:SOIC-8 封裝:Tube |

| THS3091DG4 | 功能描述:高速運算放大器 Single Lo-Distort Current Feedback RoHS:否 制造商:Texas Instruments 通道數(shù)量:1 電壓增益 dB:116 dB 輸入補償電壓:0.5 mV 轉(zhuǎn)換速度:55 V/us 工作電源電壓:36 V 電源電流:7.5 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:SOIC-8 封裝:Tube |

| THS3091DR | 功能描述:高速運算放大器 Single Lo-Distort Current Feedback RoHS:否 制造商:Texas Instruments 通道數(shù)量:1 電壓增益 dB:116 dB 輸入補償電壓:0.5 mV 轉(zhuǎn)換速度:55 V/us 工作電源電壓:36 V 電源電流:7.5 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:SOIC-8 封裝:Tube |

| THS3091DRG4 | 功能描述:高速運算放大器 Single Lo-Distort Current Feedback RoHS:否 制造商:Texas Instruments 通道數(shù)量:1 電壓增益 dB:116 dB 輸入補償電壓:0.5 mV 轉(zhuǎn)換速度:55 V/us 工作電源電壓:36 V 電源電流:7.5 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:SOIC-8 封裝:Tube |

| THS3091EVM | 功能描述:放大器 IC 開發(fā)工具 THS3091 Eval Module RoHS:否 制造商:International Rectifier 產(chǎn)品:Demonstration Boards 類型:Power Amplifiers 工具用于評估:IR4302 工作電源電壓:13 V to 23 V |

發(fā)布緊急采購,3分鐘左右您將得到回復。