- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄225404 > UEP0J331MED.PD (Nichicon Corporation) USB Positive Overvoltage Protection Controller PDF資料下載

參數(shù)資料

| 型號(hào): | UEP0J331MED.PD |

| 廠商: | Nichicon Corporation |

| 英文描述: | USB Positive Overvoltage Protection Controller |

| 中文描述: | 鋁電解電容器 |

| 文件頁數(shù): | 1/1頁 |

| 文件大?。?/td> | 77K |

| 代理商: | UEP0J331MED.PD |

U

1

E

2

P

3

1

4

A

5

4

6

7

0

8

M

9

D

10

D

11

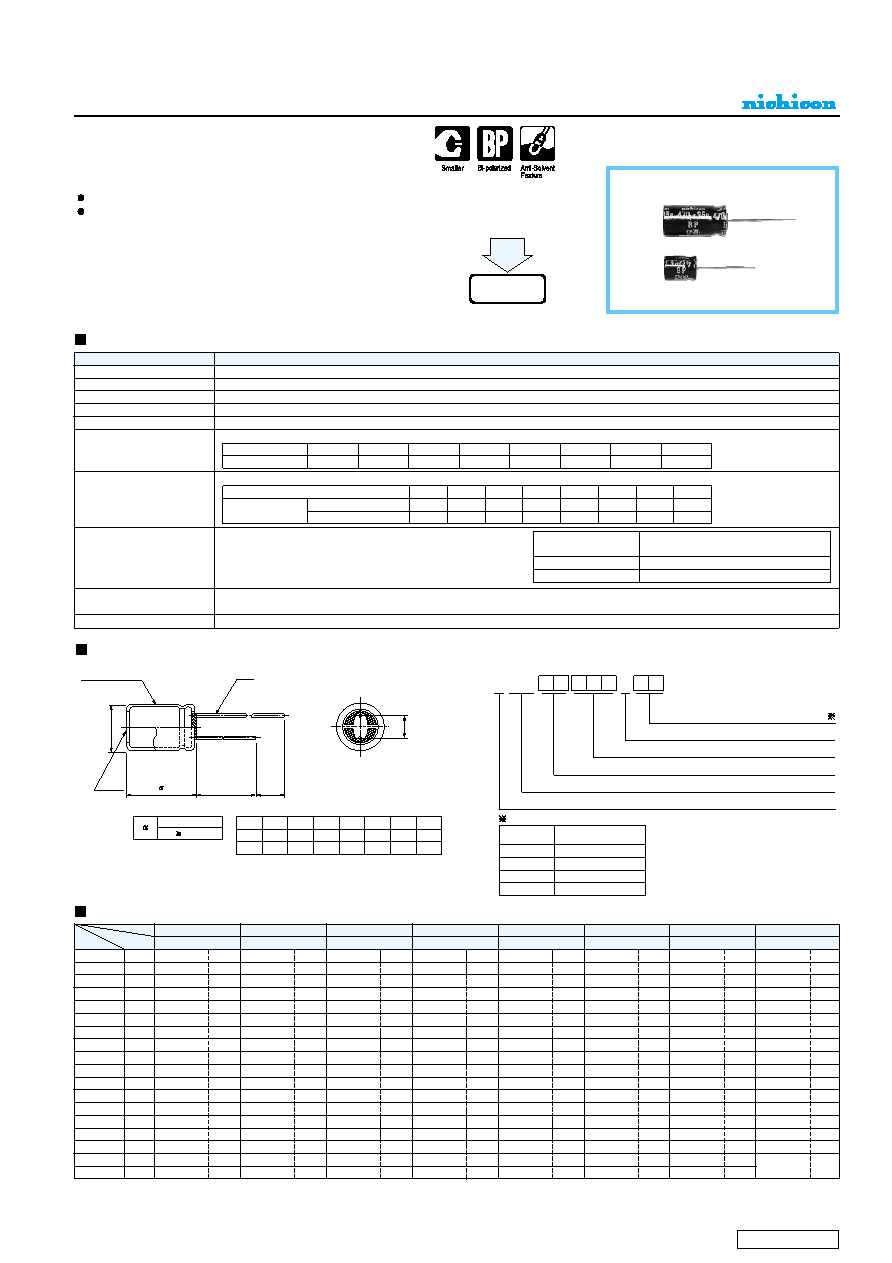

Configuration

Capacitance tolerance (±20%)

Rated Capacitance (47mF)

Rated voltage (10V)

Series name

Type

fD

P

fd

5

2.0

0.5

6.3

2.5

0.5

8

3.5

0.6

10

5.0

0.6

12.5

5.0

0.6

16

7.5

0.8

18

7.5

0.8

(L < 20) 1.5

(L 20) 2.0

f D

5

Pb-free leadwire

Pb-free PET sleeve

DD

6.3

ED

8á 10

PD

12.5 ~ 18

HD

Configuration

(mm)

(f6.3up)

15MIN

4MIN

Sleeve (P.E.T.)

Pressure

relief vent

fd

fD

+

0.5

MAX

L+ MAX

P

±

0.5

ALUMINUM ELECTROLYTIC CAPACITORS

EP

series

Bi-Polarized, Wide Temperature Range

1 ~ 2 ranks smaller than ET series.

Adapted to the RoHS directive (2002/95/EC).

Radial Lead Type

Type numbering system (Example : 10V 47F)

Specifications

Category Temperature Range

Rated Voltage Range

Rated Capacitance Range

Capacitance Tolerance

Leakage Current

tan

δ

Stability at Low Temperature

Endurance

Shelf Life

Marking

Performance Characteristics

Item

– 55 ~ +105°C

6.3 ~ 100V

0.47 ~ 6800F

± 20% at 120Hz, 20°C

After 5 minutes' application of rated voltage, leakage current is not more than 0.03CV or 3 (A), whichever is greater.

Printed with white color letter on black sleeve.

Measurement frequency : 120Hz, Temperature : 20°C

Measurement frequency : 120Hz

After 1000 hours' application of rated voltage at 105°C, with the

polarity inverted every 250 hours, capacitors meet the

characteristic requirements listed at right.

After storing the capacitors under no load at 105°C for 1000 hours, and after performing voltage treatment based on JIS C 5101-4

clause 4.1 at 20°C, they will meet the specified value for endurance characteristics listed above.

EP

ET

Rated voltage (V)

tan

δ (MAX.)

6.3

0.24

10

0.24

16

0.20

25

0.20

35

0.16

50

0.14

63

0.12

100

0.10

Z– 25°C / Z+20°C

Z– 40°C / Z+20°C

Rated voltage (V)

Impedance ratio

ZT / Z20 (MAX.)

6.3

4

10

3

8

16

2

6

25

2

4

35

2

3

50

2

3

63

2

3

100

2

3

Smaller

Leakage current

tan

δ

Capacitance change

Within ±25% of initial value (6.3~16V)

Within ±20% of initial value (25~100V)

150% or less of initial specified value

Initial specified value or less

Please refer to page 21, 22, 23 about the formed or taped product spec.

Please refer to page 3 for the minimum order quantity.

5

× 11

5

× 11

6.3

× 11

6.3

× 11

6.3

× 11

8

× 11.5

10

× 16

12.5

× 20

12.5

× 20

16

× 25

18

× 35.5

37

45

54

90

150

240

290

510

910

1200

1520

5

× 11

5

× 11

5

× 11

5

× 11

5

× 11

6.3

× 11

8

× 11.5

8

× 11.5

10

× 12.5

10

× 20

12.5

× 25

16

× 25

16

× 31.5

8

12

20

25

30

50

97

140

170

300

510

Rated

ripple

20

24

40

68

98

130

225

405

535

680

7

10

15

18

22

37

63

77

105

190

340

460

590

21

30

51

72

86

160

290

350

465

805

27

40

49

67

110

195

265

345

605

1070

1400

5

× 11

5

× 11

5

× 11

6.3

× 11

8

× 11.5

10

× 16

10

× 16

12.5

× 20

16

× 25

16

× 31.5

18

× 35.5

0.47

1

2.2

3.3

4.7

10

22

33

47

100

220

330

470

1000

2200

3300

4700

6800

Dimensions

R47

010

2R2

3R3

4R7

100

220

330

470

101

221

331

471

102

222

332

472

682

5

× 11

5

× 11

6.3

× 11

8

× 11.5

8

× 11.5

10

× 12.5

10

× 20

12.5

× 25

16

× 25

16

× 31.5

18

× 35.5

45

54

90

150

185

260

460

820

1110

1430

1830

0J

Rated Ripple (mArms) at 105°C 120Hz

6.3

1A

10

1C

16

1E

25

1V

35

1H

50

1J

2A

63

100

5

× 11

5

× 11

5

× 11

6.3

× 11

8

× 11.5

10

× 12.5

10

× 16

10

× 20

12.5

× 25

16

× 31.5

18

× 35.5

5

× 11

5

× 11

6.3

× 11

8

× 11.5

8

× 11.5

10

× 16

12.5

× 20

12.5

× 20

12.5

× 25

16

× 31.5

5

× 11

6.3

× 11

6.3

× 11

8

× 11.5

10

× 12.5

10

× 16

12.5

× 20

16

× 25

16

× 31.5

18

× 35.5

5

× 11

6.3

× 11

6.3

× 11

6.3

× 11

8

× 11.5

10

× 16

12.5

× 20

12.5

× 20

16

× 25

18

× 35.5

27

46

56

67

110

215

320

380

670

1140

Case size

φD×L (mm)

V

Code

Cap. (F)

Please refer to page 21 about the end seal configulation.

CAT.8100V

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| UER | FEMALE, STRAIGHT TWO PART BOARD CONNECTOR, SOLDER |

| UFD14P50/501L7 | FIBER OPTIC SPLITTER/COUPLER, 1X4PORT, 50/50, LC/UPC CONNECTOR |

| UFD66A50/501R3 | FIBER OPTIC SPLITTER/COUPLER, 6X6PORT, 50/50, SC/PC CONNECTOR |

| UFD66A50/501R2 | FIBER OPTIC SPLITTER/COUPLER, 6X6PORT, 50/50, FC/APC CONNECTOR |

| UFD66A50/501R1 | FIBER OPTIC SPLITTER/COUPLER, 6X6PORT, 50/50, FC/PC CONNECTOR |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| UEP0J331MHD | 制造商:NICHICON 制造商全稱:Nichicon corporation 功能描述:ALUMINUM ELECTROLYTIC CAPACITORS |

| UEP0J331MPD | 功能描述:鋁質(zhì)電解電容器 - 帶引線 6.3volts 330uF 0.2L/S RoHS:否 制造商:Kemet 引線類型: 電容:220 uF 容差:20 % 電壓額定值:25 V 工作溫度范圍: 端接類型:Radial 外殼直徑:8 mm 外殼長度:11 mm 引線間隔:5 mm 產(chǎn)品:General Purpose Electrolytic Capacitors 封裝:Bulk |

| UEP0J332MDD | 制造商:NICHICON 制造商全稱:Nichicon corporation 功能描述:ALUMINUM ELECTROLYTIC CAPACITORS |

| UEP0J332MED.PD | 制造商:NICHICON 制造商全稱:Nichicon corporation 功能描述:ALUMINUM ELECTROLYTIC CAPACITORS |

| UEP0J332MHD | 功能描述:鋁質(zhì)電解電容器 - 帶引線 6.3volts 3300uF 0.2L/S RoHS:否 制造商:Kemet 引線類型: 電容:220 uF 容差:20 % 電壓額定值:25 V 工作溫度范圍: 端接類型:Radial 外殼直徑:8 mm 外殼長度:11 mm 引線間隔:5 mm 產(chǎn)品:General Purpose Electrolytic Capacitors 封裝:Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。