- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄376431 > UPD75112GF (NEC Corp.) 4-Bit Single Chip-Microcomputer PDF資料下載

參數(shù)資料

| 型號: | UPD75112GF |

| 廠商: | NEC Corp. |

| 英文描述: | 4-Bit Single Chip-Microcomputer |

| 中文描述: | 4位單片微機(jī) |

| 文件頁數(shù): | 51/56頁 |

| 文件大?。?/td> | 499K |

| 代理商: | UPD75112GF |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁當(dāng)前第51頁第52頁第53頁第54頁第55頁第56頁

51

μ

PD75112(A), 75116(A)

Recommended Condition Symbol

IR30-00-1

VP15-00-1

WS60-00-1

Table 13-2 Insertion Type Soldering Conditions

μ

PD75112CW(A)-

×××

:

64-pin plastic shrink DIP (750 mil)

μ

PD75116CW(A)-

×××

:

64-pin plastic shrink DIP (750 mil)

13.

Recommended Soldering Conditions

The

μ

PD75112(A) and 75116(A) should be soldered and

mounted under the conditions recommended in the

table below.

For detail of recommended soldering conditions, refer

to the information document

“Surface Mount Technol-

ogy Manual” (IEI-1207)

.

For soldering methods and conditions other than those

recommended below, contact our sales personnel.

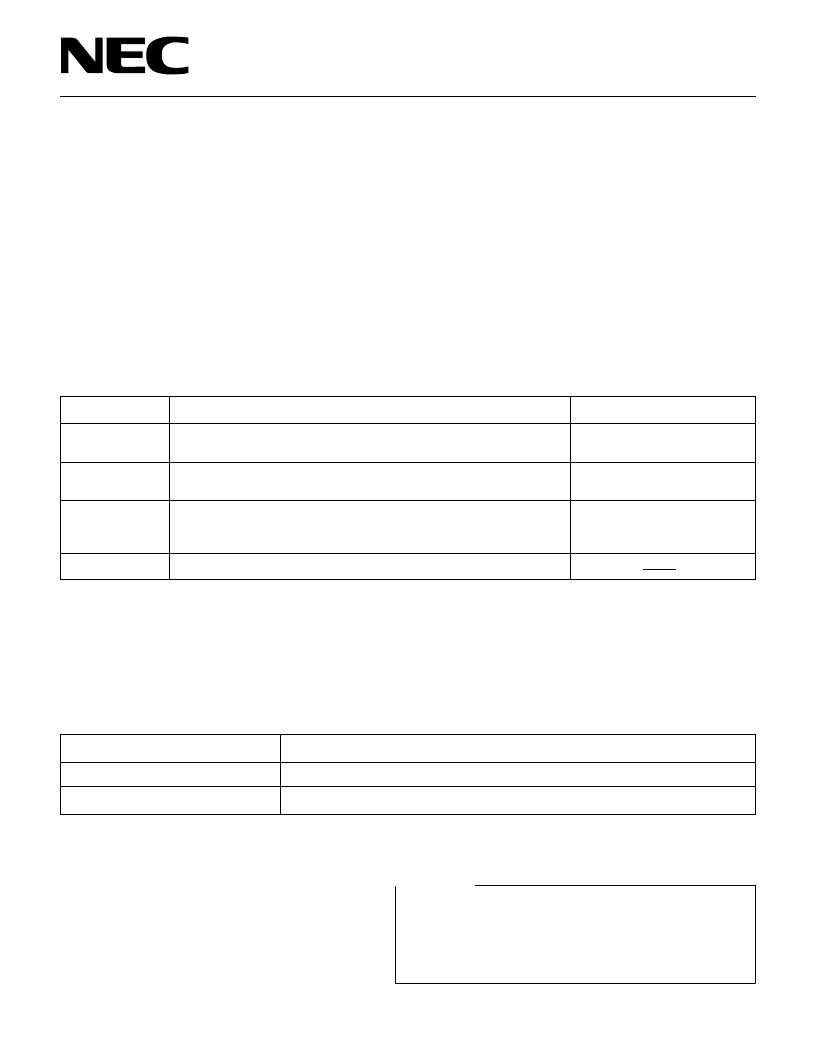

Table 13-1 Surface Mounting Type Soldering Conditions

μ

PD75112GF(A)-

×××

-3BE : 64-pin plastic QFP (14

×

20mm)

μ

PD75116GF(A)-

×××

-3BE : 64-pin plastic QFP (14

×

20mm)

Soldering Method

Infrared reflow

VPS

Wave soldering

Pin part heating

Soldering Conditions

Package peak temperature: 230

°

C Duration: 30 sec. max. (at 210

°

C above)

Number of times: Once

Package peak temperature: 215

°

C Duration: 40 sec. max. (at 200

°

C above)

Number of times: Once

Solder bath temperature: 260

°

C max. Duration: 10 sec. max.

Number of times: Once

Preliminary heat temperature: 120

°

C max. (Package surface temperature)

Pin part temperature: 300

°

C max. Duration: 3 sec. max. (per device side)

Note: Use more than one soldering method should

be avoided (except in the case of pin part).

Soldering Method

Wave soldering (lead part only)

Pin part heating

Soldering Conditions

Solder bath temperature: 260

°

C max. Duration: 10 sec. max.

Pin part temperature: 260

°

C max. Duration: 10 sec. max.

Note: Wave soldering is only for the lead part in order

that jet solder can not contact with the chip.

#

Notice

A version of this product with improved recommended

soldering conditions is available.

For details (improvements such as infrared reflow

peak temperature extension (235

°

C, number of times:

twice, relaxation of time limit), contact NEC sales

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| UPD75112GFA | 4-Bit Single Chip-Microcomputer |

| UPD75116 | 4-Bit Single Chip-Microcomputer |

| UPD75116A | 4-Bit Single Chip-Microcomputer |

| UPD75116CW | 4-Bit Single Chip-Microcomputer |

| UPD75206GF | 4-BIT SINGLE-CHIP MICROCOMPUTER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| UPD75208 | 制造商:Panasonic Industrial Company 功能描述:IC |

| UPD753012AGC-P33-8BT-A | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD753016AGC-P29-8BT | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD75304GF-407-3B9 | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD75306G182 | 制造商:Panasonic Industrial Company 功能描述:IC |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。