- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄384045 > UPD75P108BCW (NEC Corp.) 4-BIT SINGLE-CHIP MICROCOMPUTER PDF資料下載

參數(shù)資料

| 型號: | UPD75P108BCW |

| 廠商: | NEC Corp. |

| 英文描述: | 4-BIT SINGLE-CHIP MICROCOMPUTER |

| 中文描述: | 4位單片機(jī) |

| 文件頁數(shù): | 36/46頁 |

| 文件大小: | 381K |

| 代理商: | UPD75P108BCW |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁當(dāng)前第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁

36

μ

PD75P108B

7.

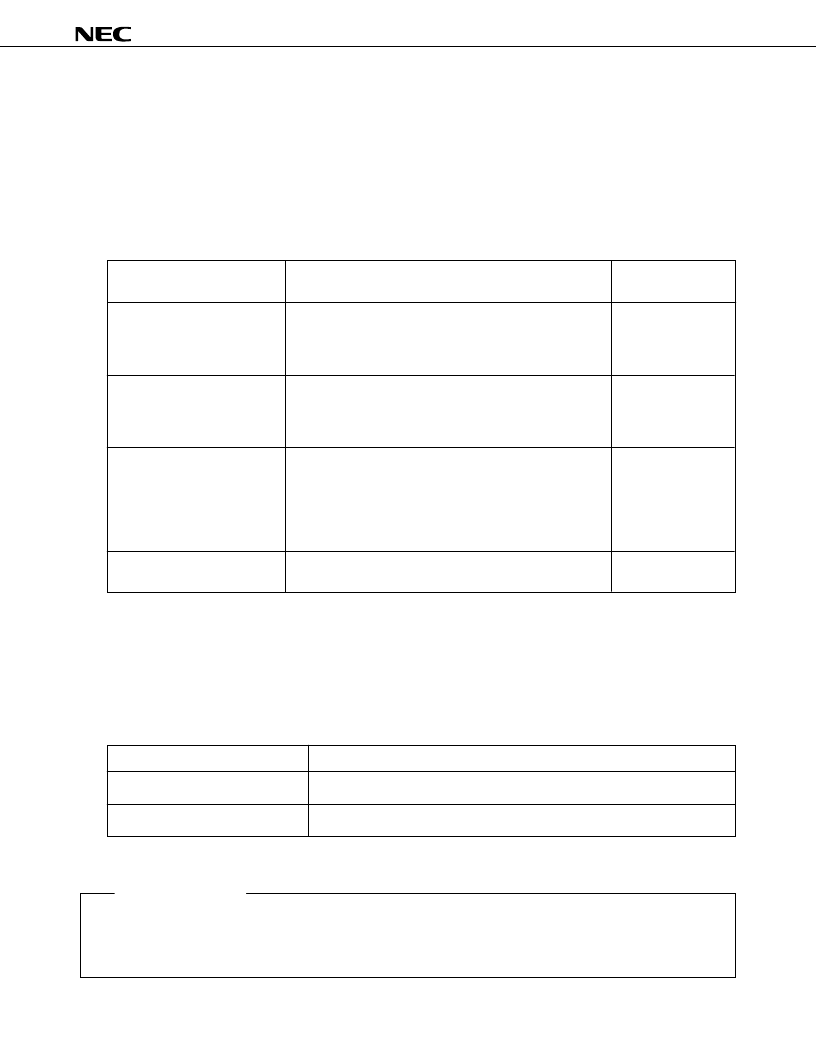

RECOMMENDED SOLDERING CONDITIONS

The

μ

PD75P108B should be mounted under the conditions recommended in the table below.

For details of recommended soldering conditions for the surface mounting type, refer to the information

document “Surface Mount Technology Manual” (IEI-1207)

For soldering methods and conditions other than those recommended below, contact our salesman.

Table 7-1 Surface Mount Type Soldering Conditions

μ

PD75P108BGF-3BE : 64-pin plastic QFP (14

×

20 mm, 1.0 mm pitch)

For Your Information

Products to improve the recommended soldering conditions are available.

(Improvements: Extension of the infrared reflow peak temperature to 235

°

C, doubled frequency, increased

life, etc.)

For further details, consult our sales personnel.

Infrared reflow

Pin part heating

Pin part heating

VP15-162-1

WS60-162-1

IR30-162-1

VPS

Recommended

Condition Symbol

Soldering Conditions

Soldering Method

Package peak temperature: 230

°

C, Duration: 30 sec. max.

(at 210

°

C or above), Number of times: Once

Time limit: 2 days

*

(thereafter 16 hours prebaking required

at 125

°

C)

Package peak temperature: 215

°

C, Duration: 40 sec. max.

(at 200

°

C or above), Number of times: 0nce

Time limit: 2 days

*

(thereafter 16 hours prebaking required

at 125

°

C)

Solder bath temperature: 260

°

C max., Duration: 10 sec. max

Number of times: Once

Preheating temperature: 120

°

C max. (package surface

temperature),

Time limit: 2days

*

(thereafter 16 hours prebaking required

at 125

°

C)

Pin part temperature: 300

°

C max., Duration 3 sec. max.

(per device lead)

Wave soldering

*

For the storage period after dry-pack decapsulation, storage conditions are max. 25

°

C, 65% 1H.

Note

Use of more than one soldering method should be avoided (except in the case of pin part heating).

Note

Ensure that the application of (wave soldering) is limited to the lead part and no solder touches

the main unit directly

.

Table 7-2 Insertion Type Soldering Conditions

μ

PD75P108BCW : 64-pin plastic shrink DIP (750 mil)

μ

PD75P108BDW : 64-pin ceramic shrink DIP (with window)

Soldering Method

Soldering Conditions

Wave Soldering (lead part only)

Pin part heating

Solder bath temperature: 260

°

C max., Duration: 10sec. max.

Pin part temperature: 260

°

C max., Duration: 10sec. max.

#

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| UPD75P108BDW | 4-BIT SINGLE-CHIP MICROCOMPUTER |

| UPD75P108BGF-3BE | 4-BIT SINGLE-CHIP MICROCOMPUTER |

| UPD780031AY | 8-BIT SINGLE-CHIP MICROCONTROLLERS |

| UPD780031AYCW | 8-BIT SINGLE-CHIP MICROCONTROLLERS |

| UPD780031AYGC | 8-BIT SINGLE-CHIP MICROCONTROLLERS |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| UPD75P3018AGC-8BT-A | 制造商:Renesas Electronics Corporation 功能描述:MCU 4BIT 75XL CISC 32KB EPROM 2.5V/3.3V/5V 80PQFP - Trays 制造商:Renesas Electronics 功能描述:75XL 6MHz Cut Tape 制造商:Renesas 功能描述:MCU 4-bit 75XL CISC 32KB EPROM 2.5V/3.3V/5V 80-Pin PQFP |

| UPD75P3018AGK-BE9 | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD75P3036GC-3B9-A | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD75P308GF-3B9 | 制造商:Renesas Electronics Corporation 功能描述:MCU 4-Bit 75XL CISC 8064Byte PROM 5V 80-Pin PQFP |

| UPD75P308GF-3BA | 制造商:Renesas Electronics Corporation 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。