- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄358620 > 1393292-5 (Tyco Electronics) Automotive Relays PDF資料下載

參數(shù)資料

| 型號: | 1393292-5 |

| 廠商: | Tyco Electronics |

| 元件分類: | 特殊繼電器 |

| 英文描述: | Automotive Relays |

| 中文描述: | 汽車繼電器 |

| 文件頁數(shù): | 1/4頁 |

| 文件大?。?/td> | 422K |

| 代理商: | 1393292-5 |

1

01-2013, Rev. 0113

www.te.com

2013 Tyco Electronics Corporation,

a TE Connectivity Ltd. company.

Datasheets and product specification ac-

cording to IEC 61810-1 and to be used only

together with the ‘Definitions’ section.

Datasheets and product data is subject to the

terms of the disclaimer and all chapters of

the ‘Definitions’ section, available at

http://relays.te.com/definitions

Datasheets, product data, ‘Definitions’ sec-

tion, application notes and all specifications

are subject to change.

Micro Relay A/VFMA

Automotive Relays

Plug-in Micro ISO Relays

1) The values apply to a resistive or inductive load with suitable spark suppression and at

maximum 13.5VDC for 12VDC or 27VDC for 24VDC load voltages.

2) For a load current duration of maximum 3s for a make/break ratio of 1:10.

3) Current and time are compatible with circuit protection by a typical automotive fuse.

Relay will make, carry and break the specified current.

4) See chapter Diagnostics of Relays in our Application Notes or consult the internet at

http://relays.te.com/appnotes/

5) Electrical endurance data are only valid for the variants with resistor.

6) Not applicable for polarity reverse loads like powerwindows

n

High current version with limiting continuous current 30A at 85°C

n

Pin assignment according to ISO 7588 part 3

n

Customized versions on request

– 24VDC versions with special contact gap

– Integrated components (e.g. diode)

– Customized marking

– Special covers (e.g. notches, release features)

– For latching version refer to Micro Relay Latching

– For low noise version refer to Micro Relay Low Noise

– For high current version refer to part number table

Typical applications

Cross carline up to 30A for example: ABS control, blower fans, cooling fan,

door control, door lock, fuel pump, heated front screen, immobilizer, interior

lights, seat control, seatbelt pretensioner, sun roof, trunk lock, valves,

window lifter, wiper control.

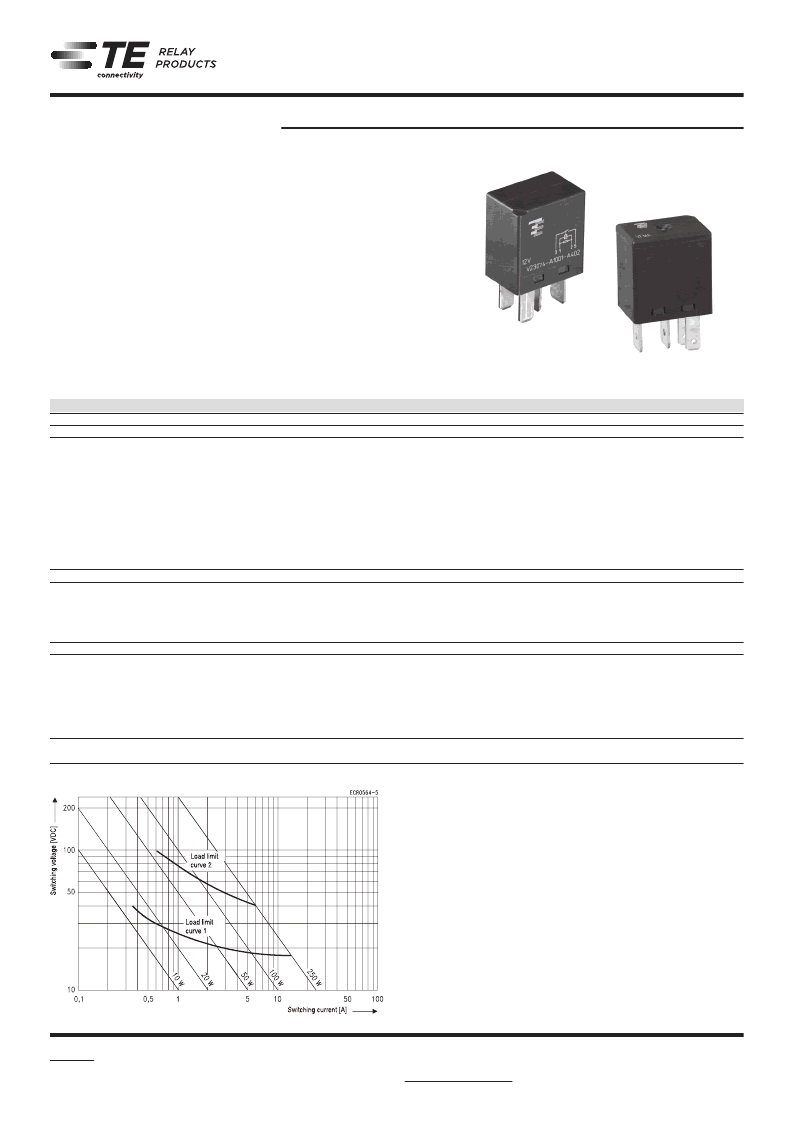

Max. DC load breaking capacity

Load limit curve 1: arc extinguishes during transit time (CO contact).

Load limit curve 2: safe shutdown, no stationary arc (NO contact).

Load limit curves measured with low inductive resistors verified for 1000 switching events.

Contact Data

Contact arrangement

Rated voltage

Limiting continuous current, form A/form B

23°C

85°C

125°C

Limiting making current

1)2)

, A/B (NO/NC)

Limiting breaking current

Limiting short-time current,

overload current, ISO 8820-3

3)

Jump start test

Contact material

Min. recommended contact load

4)

Initial voltage drop

NO contact at 10A, typ./max.

NC contact at 10A, typ./max.

Frequency of operation

Electrical endurance

5)

resistive load at 14VDC

resistive load at 28VDC

Mechanical endurance

Form A – Standard

1 form A, 1 NO

12VDC

30A

25A

10A

120A

30A

Form C

Form A – HC

1 form A, 1 NO

12VDC

1 form A, 1 NO

24VDC

NO/NC

30A

25A

10A

120A

20A

1 form C, 1 CO

12VDC

NO/NC

30/20A

25/15A

10/8A

120/40A

30/15A

1 form C, 1 CO

24VDC

6)

30/20A

25/15A

10/8A

120/20A

20/10A

35A

30A

15A

120A

30A

1.35 x 25A, 1800s

2.00 x 25A, 5s

3.50 x 25A, 0.5s

6.00 x 25A, 0.1s

24VDC for 5min conducting nominal current at 23°C

>1x10

5

ops.

25A

>1x10

5

ops.

15A

1.35 x 25A, 1800s

2.00 x 25A, 5s

3.50 x 25A, 0.5s

6.00 x 25A, 0.1s

1.35 x 30A, 1800s

2.00 x 30A, 5s

3.50 x 30A, 0.5s

6.00 x 30A, 0.1s

silver based

1A at 5VDC

6 ops./min (0.1Hz)

>1x10

5

ops.

25A (NO)

15/200mV

20/250mV

>1x10

5

ops.

30A

>1x10

5

ops.

15A (NO)

>1x10

5

ops.

10A (NC)

typ. 10

7

ops.

F074_fcw1_bw

FVFMA_fcw1c

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 8-1393292-9 | Automotive Relays |

| 8-1393292-4 | Automotive Relays |

| 3-1414773-5 | Automotive Relays |

| 3.9BS | surface mount silicon Zener diodes |

| 3.9HC | surface mount silicon Zener diodes |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 1393293-7 | 制造商:TE Connectivity 功能描述:VFMA-15F41=VFMA - Bulk 制造商:TE Connectivity 功能描述:RELAY AUTOMOTIVE SPDT 12V 制造商:TE CONNECTIVITY P&B 功能描述:Electromechanical Relay SPDT |

| 1393293-8 | 功能描述:通用繼電器 25 AMP 12VDC SPDT RoHS:否 制造商:Omron Electronics 觸點形式:1 Form A (SPST-NO) 觸點電流額定值:150 A 線圈電壓:24 VDC 線圈電阻:144 Ohms 線圈電流:167 mA 切換電壓:400 V 安裝風(fēng)格:Chassis 觸點材料: |

| 1393297-1 | 制造商:TE Connectivity / AMP 功能描述: 制造商:TE CONNECTIVITY 功能描述: |

| 1393297-8 | 制造商:TE Connectivity 功能描述:Electromechanical Relay SPDT 120(NO)/45(NC)A 12VDC 79.5Ohm Plug-In |

| 13933 | 功能描述:TOOL NUTDRVR M4.5 X 50MM RoHS:否 類別:工具 >> 螺釘和螺母驅(qū)動器 系列:- 標準包裝:1 系列:- 類型:六角扳手(內(nèi)六角扳手)- 偏移 尺寸:0.098"(2.5mm) 特點:- 長度 - 葉片:0.70"(18mm) 長度 - 總體:2.17"(55mm) 重量:0.01 磅(4.54g) 其它名稱:35112WI |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。