- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄68796 > 5962-9089504QCA (TEXAS INSTRUMENTS INC) OP-AMP, 40 uV OFFSET-MAX, 1.9 MHz BAND WIDTH, CDIP14 PDF資料下載

參數(shù)資料

| 型號(hào): | 5962-9089504QCA |

| 廠商: | TEXAS INSTRUMENTS INC |

| 元件分類: | 運(yùn)算放大器 |

| 英文描述: | OP-AMP, 40 uV OFFSET-MAX, 1.9 MHz BAND WIDTH, CDIP14 |

| 封裝: | CERAMIC, DIP-14 |

| 文件頁(yè)數(shù): | 15/36頁(yè) |

| 文件大?。?/td> | 916K |

| 代理商: | 5962-9089504QCA |

第1頁(yè)第2頁(yè)第3頁(yè)第4頁(yè)第5頁(yè)第6頁(yè)第7頁(yè)第8頁(yè)第9頁(yè)第10頁(yè)第11頁(yè)第12頁(yè)第13頁(yè)第14頁(yè)當(dāng)前第15頁(yè)第16頁(yè)第17頁(yè)第18頁(yè)第19頁(yè)第20頁(yè)第21頁(yè)第22頁(yè)第23頁(yè)第24頁(yè)第25頁(yè)第26頁(yè)第27頁(yè)第28頁(yè)第29頁(yè)第30頁(yè)第31頁(yè)第32頁(yè)第33頁(yè)第34頁(yè)第35頁(yè)第36頁(yè)

TLC2654, TLC2654A

Advanced LinCMOS

LOW-NOISE CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS020G – NOVEMBER 1988 – REVISED APRIL 2001

22

POST OFFICE BOX 655303

DALLAS, TEXAS 75265

APPLICATION INFORMATION

theory of operation (continued)

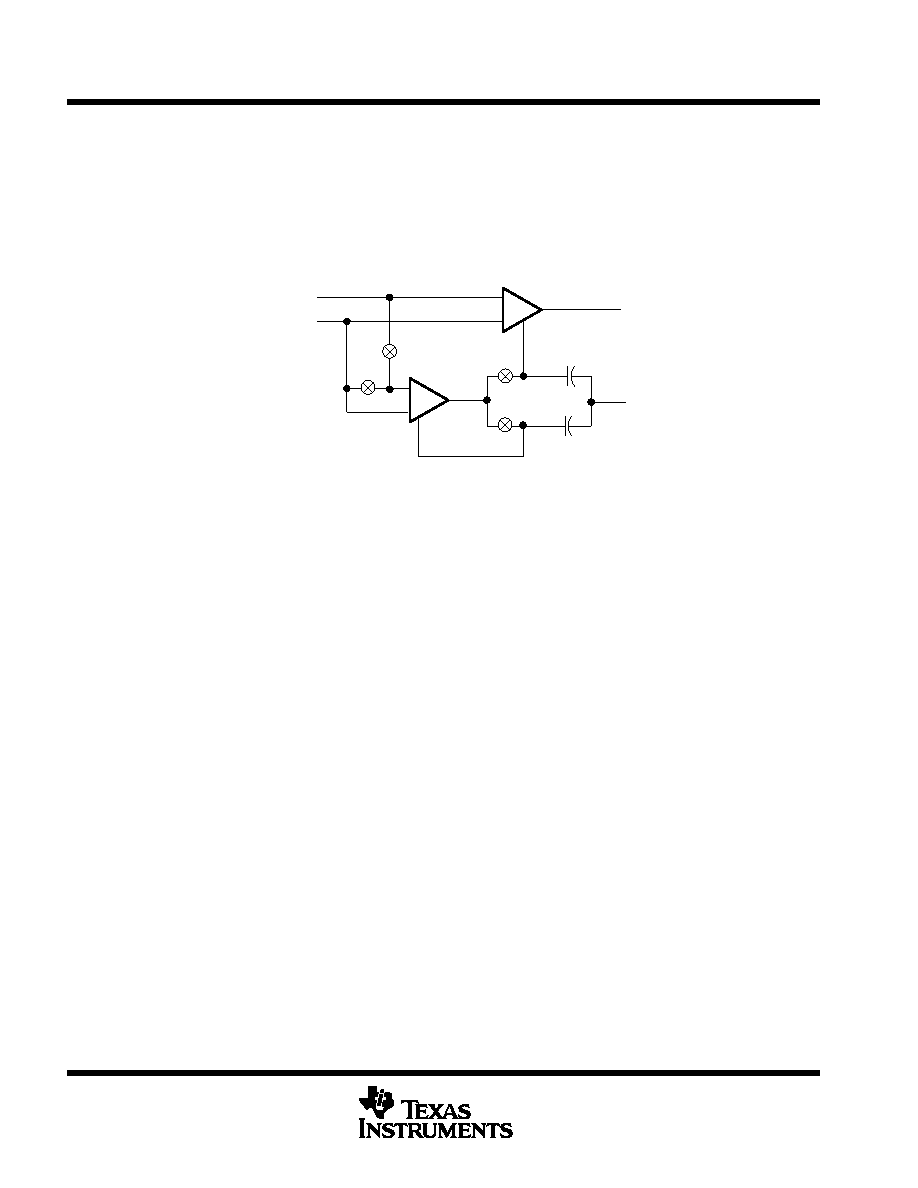

During the nulling phase, switch A is closed, shorting the nulling amplifier inputs together and allowing the nulling

amplifier to reduce its own input offset voltage by feeding its output signal back to an inverting input node.

Simultaneously, external capacitor CXA stores the nulling potential to allow the offset voltage of the amplifier to

remain nulled during the amplifying phase.

Null

IN +

IN –

Main

VDD –

CXA

CXB

B

A

B

A

+

–

5

4

10

OUT

7

Pin numbers shown are for the D (14 pin), J, and N packages.

Figure 35. TLC2654 Simplified Block Diagram

During the amplifying phase, switch B is closed, connecting the output of the nulling amplifier to a noninverting

input of the main amplifier. In this configuration, the input offset voltage of the main amplifier is nulled. Also,

external capacitor CXB stores the nulling potential to allow the offset voltage of the main amplifier to remain

nulled during the next nulling phase.

This continuous chopping process allows offset voltage nulling during variations in time and temperature and

over the common-mode input voltage range and power supply range. In addition, because the low-frequency

signal path is through both the null and main amplifiers, extremely high gain is achieved.

The low-frequency noise of a chopper amplifier depends on the magnitude of the component noise prior to

chopping and the capability of the circuit to reduce this noise while chopping. The use of the Advanced LinCMOS

process, with its low-noise analog MOS transistors and patent-pending input stage design, significantly reduces

the input noise voltage.

The primary source of nonideal operation in chopper-stabilized amplifiers is error charge from the switches. As

charge imbalance accumulates on critical nodes, input offset voltage can increase especially with increasing

chopping frequency. This problem has been significantly reduced in the TLC2654 by use of a patent-pending

compensation circuit and the Advanced LinCMOS process.

The TLC2654 incorporates a feed-forward design that ensures continuous frequency response. Essentially, the

gain magnitude of the nulling amplifier and compensation network crosses unity at the break frequency of the

main amplifier. As a result, the high-frequency response of the system is the same as the frequency response

of the main amplifier. This approach also ensures that the slewing characteristics remain the same during both

the nulling and amplifying phases.

The primary limitation on ac performance is the chopping frequency. As the input signal frequency approaches

the chopper’s clock frequency, intermodulation (or aliasing) errors result from the mixing of these frequencies.

To avoid these error signals, the input frequency must be less than half the clock frequency. Most choppers

available today limit the internal chopping frequency to less than 500 Hz in order to eliminate errors due to the

charge imbalancing phenomenon mentioned previously. However, to avoid intermodulation errors on a 500-Hz

chopper, the input signal frequency must be limited to less than 250 Hz.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 5962-9089504QPA | OP-AMP, 40 uV OFFSET-MAX, 1.9 MHz BAND WIDTH, CDIP8 |

| 5962-9089502M2A | OP-AMP, 50 uV OFFSET-MAX, 1.9 MHz BAND WIDTH, CQCC20 |

| 5962-9089601M2A | OP-AMP, 105 uV OFFSET-MAX, 13 MHz BAND WIDTH, CQCC20 |

| 5962-9089601MPA | OP-AMP, 105 uV OFFSET-MAX, 13 MHz BAND WIDTH, CDIP8 |

| 5962-9089603Q2A | OP-AMP, 105 uV OFFSET-MAX, 13 MHz BAND WIDTH, CQCC20 |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 5962-9089504QPA | 制造商:Texas Instruments 功能描述:SP Amp Chopper Stabilization Single |

| 5962-9089601M2A | 制造商:Texas Instruments 功能描述:OP Amp Single GP 制造商:Texas Instruments 功能描述:OP AMP SGL GP 19V 20LCCC - Rail/Tube |

| 5962-9089601MPA | 制造商:Texas Instruments 功能描述:OP Amp Single GP |

| 5962-9089603Q2A | 制造商:Texas Instruments 功能描述:OP Amp Single GP 制造商:Texas Instruments 功能描述:OP AMP SGL GP 19V 20LCCC - Rail/Tube |

| 5962-9089901M | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。