- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄360597 > 92260 OVERHEAD IONISER 61CM PDF資料下載

參數(shù)資料

| 型號: | 92260 |

| 英文描述: | OVERHEAD IONISER 61CM |

| 中文描述: | 架空IONISER 61厘米 |

| 文件頁數(shù): | 4/6頁 |

| 文件大?。?/td> | 82K |

| 代理商: | 92260 |

PPE-5060.E

Page 4 of 6

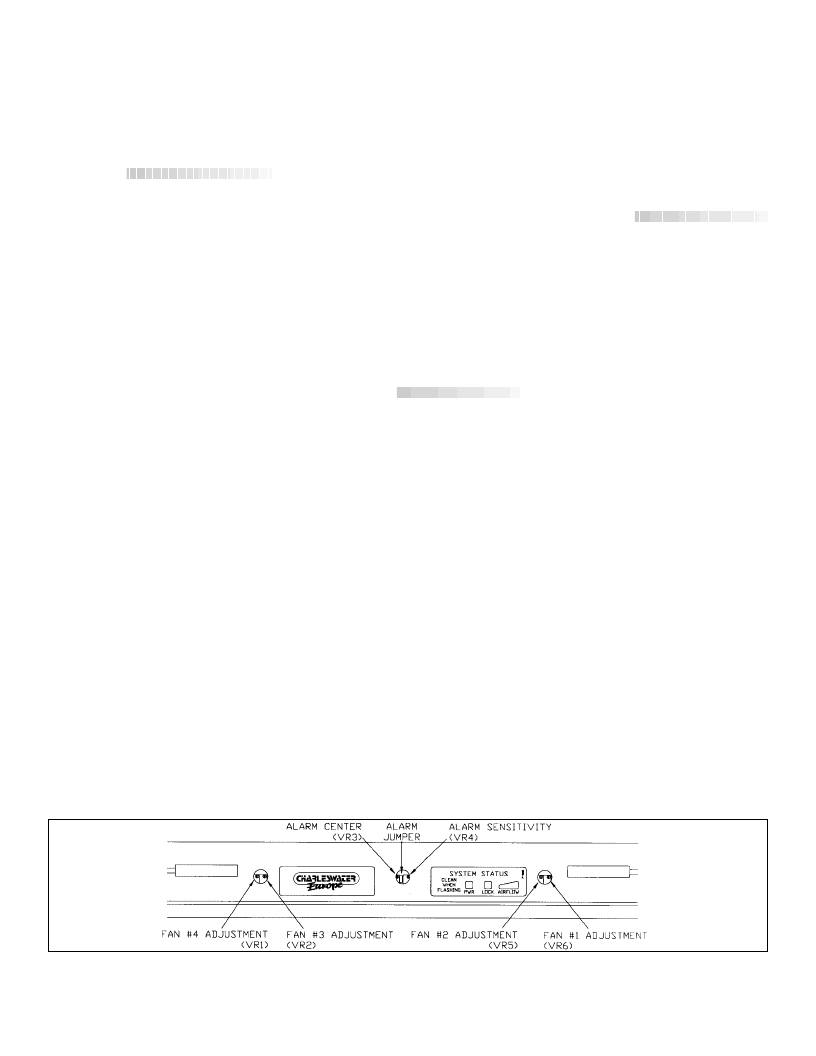

Figure 4. Calibrating C/E Ioniser

Unit 17. Millbrook Business Park, Sybron Way Crowborough, East Sussex TN6 3JZ United Kingdom

Phone: 00 44 (0) 1892-665313, Fax: 00 44 (0) 1892-668838 E-mail: info@charleswater.co.uk, Internet: www.charleswater.co.uk

ALARM JUMPER

- this jumper is

normally installed at the factory and

provides an audible alarm to

supplement the flashing red PWR light

when the unit needs cleaning. Some

units have a small switch in place of the

jumper.

Operation

After the unit is mounted securely and

connected to a properly wired outlet,

turn the key switch to the set position.

The performance of the ioniser is

directly related to the airflow on the area

to be protected. Generally, try to use

the highest setting possible without

disturbing the operator or the work in

process.

After allowing the unit to run for several

minutes, a charged plate monitor can be

used to check the balance and

performance. We recommend doing

this at the time of the initial installation,

so that data can be collected and saved

for future reference. Place the charged

plate directly under each fan and record

the float (balance) voltage. If all fans

are offset slightly in the same direction,

the “+” or “-” BAL buttons can be used

to correct the offset. If the balance

varies from a positive offset to a

negative offset between fans, the

individual fan zone controls can be

manipulated as required.

It is not uncommon to find differences

between ionisers from bench to bench

or even between fans on ionisers during

initial setup. This is often caused by the

presence of objects on or around the

bench. Large metal objects nearby or

machines or equipment on the bench

will often cause a shift in the offset

voltage at that area. The individual

zone controls of the C/E ionisers allow

this to be compensated for during initial

setup.

After balance offsets have been

checked, the decay performance of

each fan should be measured and

recorded. This information will be

useful to establish a maintenance

schedule. When decay times begin to

increase significantly, or if the red PWR

light begins to flash, emitter cleaning is

usually indicated. By recording the time

intervals between the first few

cleanings, a maintenance schedule can

be developed.

After initial setup and testing has been

done, the key switch can be set to the

LOCK position and normal workstation

use resumed.

If the ioniser is used in a manner not

specified by the manufacturer, the

protection provided by the ioniser

may be impaired.

Maintenance

By nature, all electric ionisers attract

contaminants to the high voltage emitter

pins. For best performance, this

contamination must be kept to a

minimum. This was a major factor in

the design process of the C/E ioniser.

Although we could not eliminate the

maintenance, we have made it far

easier and much cleaner than ever

before.

Turn the key switch to the OFF

position.

Grasp the cassette ejector levers at

the center and pivot outward about

90 degrees.

Grasping the right and left corners,

pull the cassette straight out of the

ioniser.

The cassettes can then be

replaced with a spare set or

removed to another area for

cleaning.

Cleaning of the cassette can be

accomplished with a stiff brush or

lint-free swab and isopropyl alcohol

or other residue-free cleaning

solvent.

The emitter cassettes or the

individual removable tungsten

emitters can also be cleaned in an

ultrasonic cleaning tank.

Calibration

See figure 4.

We recommend re-calibration every 12

months maximum, however, most users

will often choose a much shorter

interval, especially if the product being

worked on is very sensitive. On very

sensitive product, we recommend

checking the calibration any time an

emitter cassette is removed and

replaced.

Warning! Do not attempt to calibrate

this unit without proper equipment

such as a charged plate monitor.

Adjustments to the calibration

controls should be performed by

authorized trained personnel only.

Balance adjustment

Using a charge plate monitor, check

each fan's balance. Use the "BAL"

switches to zero the unit. If the fans are

a little out of balance with each other

use the fan adjustment pots to equalize

them. VR5,6 and VR1,2 on 122cm

model.

相關PDF資料 |

PDF描述 |

|---|---|

| 9226 | KABEL PARALLEL 36 ST / 36 BUCHSE 2M |

| 92270 | BRADY BOYS-OUT OF SERV Inhalt pro Packung: 2 Stk. |

| 256704 | Evaluation Kit for the MAX1213N, MAX1214N |

| 256705 | FLOOR STAND-DANGER |

| 256706 | Evaluation Kit for the MAX1213, MAX1214, MAX1215 |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| 92261 | 功能描述:NUTDRIVER INCH W/CUSHION GRP 7/3 制造商:wiha 系列:* 零件狀態(tài):在售 標準包裝:1 |

| 9226-10368 | 制造商:Leach International Corporation 功能描述:CONTENT MANAGER - Bulk |

| 9226-10369 | 制造商:Leach International Corporation 功能描述:CONTACT PM FOR PRICING ** - Bulk |

| 922-6106-010 | 制造商: 功能描述: 制造商:undefined 功能描述: |

| 9226-10638 | 制造商:Leach International Corporation 功能描述:CONTENT MANAGER - Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復。