- 您現(xiàn)在的位置:買賣IC網 > PDF目錄362330 > AN1354 SINGLE-PHASE INDUCTION MOTOR DRIVE FOR REFRIGERATOR COMPRESSOR APPLICATION PDF資料下載

參數(shù)資料

| 型號: | AN1354 |

| 英文描述: | SINGLE-PHASE INDUCTION MOTOR DRIVE FOR REFRIGERATOR COMPRESSOR APPLICATION |

| 中文描述: | 單相異步電機驅動的冷柜壓縮機的應用 |

| 文件頁數(shù): | 9/10頁 |

| 文件大?。?/td> | 118K |

| 代理商: | AN1354 |

APPLICATION NOTE

9/10

Case 1

(Hyst. Thres. = 5.3°C)

Case 2

(Hyst. Threh. = 4.2°C)

MEASURE

Compressor ON time

12' 50''

9' 10''

Compressor OFF time

16' 20''

15' 10''

Average power during

ON time

136 W

138 W

CALCULATION

Cycle period

29' 10''

24' 20''

Duty cycle

0.44

0.38

Average power

consumption

60 W

52 W

Table 1: Power consumption versus Hysteresis threshold

So, it is shown that reducing the temperature ripple improves the appliance efficiency. This is can be ex-

plained by the fact that the useful energy is not wasted in vain.

The Case 2 control law enables to save 8 W, just by reducing the threshold level by a little bit more than 1 °C.

For electromechanically controlled refrigerators, where the temperature ripple is in the range of 10-20 °C, a

decrease down to a few degree Celsius, will enable to save up to 20 % of energy consumption. This means

a 18 W saving for a 140 W compressor (90 W average power with a 2/3 duty cycle).

Reducing the temperature ripple changes the compressor behavior. The motor running cycle frequency is

increasing. In our example, this frequency increases by around 20 % (2.06 cycles per hour with Case 1, and

2.46 cycles per hour with Case 2). This is not a problem for electronic switches where the cycle length of life

isfarfromthepoorcapabilityofelectromechanicalswitches.Forthemotorpointofview,thehighernumber

of cycles should not reduce its reliability as:

I

Its temperature ripple is decreased thanks to a higher cycle frequency

I

The start winding conduction length is reduced thanks to an electronic control instead of a thermal-active

solution (PTC)

I

An overcurrent protection is ensured by the MCU, that reduces the motor stress.

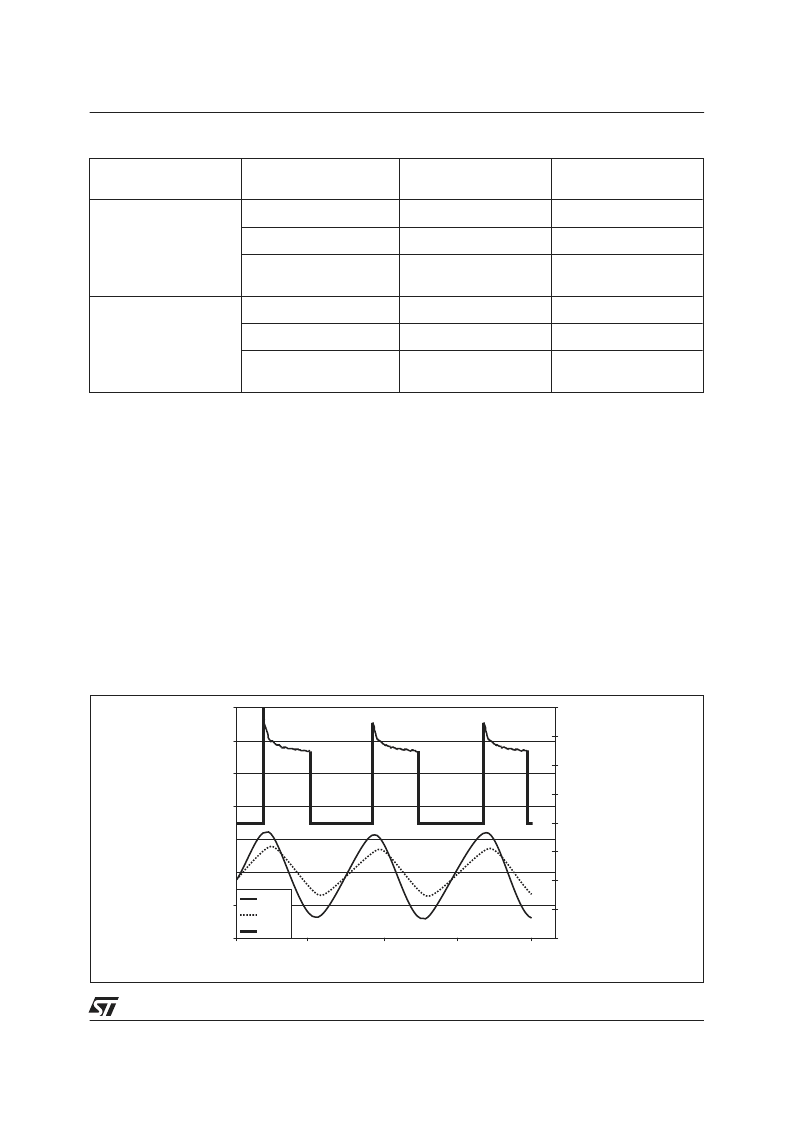

-24

0:00:00

-22

-20

-18

-16

-14

-12

-10

0:20:00

0:40:00

1:00:00

1:20:00

Time

T

0

50

100

150

200

P

Evap.

Cab.

Power

Fig. 11 Temperature control (Case 1)

相關PDF資料 |

PDF描述 |

|---|---|

| AN1358S(AN6562S) | Voltage-Feedback Operational Amplifier |

| AN6562) | Voltage-Feedback Operational Amplifier |

| AN135 | Sensor Circuits and Digitally Controlled Potentiometers |

| AN2012S | Optoelectronic |

| AN2012SB | Optoelectronic |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| AN1358 | 制造商:PANASONIC 制造商全稱:Panasonic Semiconductor 功能描述:Dual Operational Amplifiers |

| AN1358S | 制造商:Panasonic Industrial Company 功能描述:IC |

| AN1358S(AN6562S) | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Voltage-Feedback Operational Amplifier |

| AN1358S-E1 | 制造商:Panasonic Industrial Company 功能描述:IC |

| AN136 | 制造商:Panasonic Industrial Company 功能描述:IC |

發(fā)布緊急采購,3分鐘左右您將得到回復。