- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄378405 > AND8112 (ON SEMICONDUCTOR) A Quasi-Resonant SPICE Model Eases Feedback Loop Designs PDF資料下載

參數(shù)資料

| 型號: | AND8112 |

| 廠商: | ON SEMICONDUCTOR |

| 英文描述: | A Quasi-Resonant SPICE Model Eases Feedback Loop Designs |

| 中文描述: | 阿準諧振SPICE模型反饋環(huán)的設(shè)計更易 |

| 文件頁數(shù): | 5/12頁 |

| 文件大小: | 205K |

| 代理商: | AND8112 |

AND8112/D

http://onsemi.com

5

1

2

3

4

5

8

7

6

NCP1207

V

D1

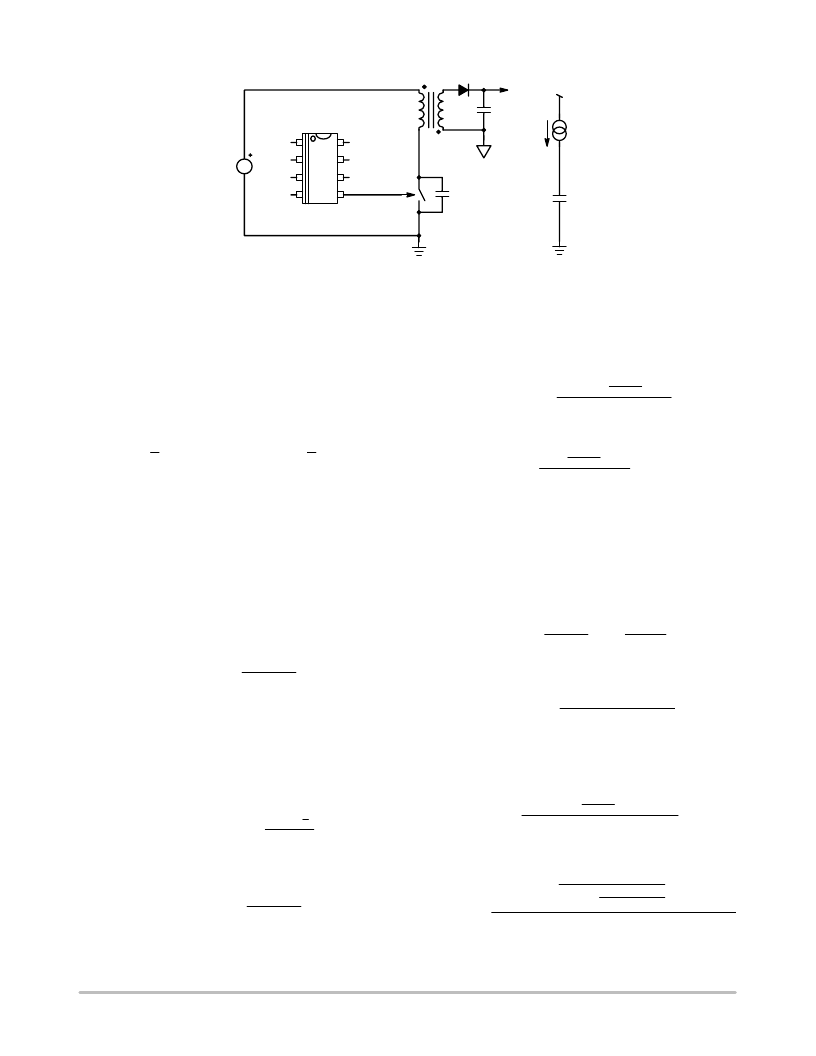

Figure 8.

V

g

C

tot

C

tot

V

g

C

out

<=>

When the power switch turns off, the primary inductor behaves like a current source that charges the C

tot

capacitor. This sequence ends

when voltage developed across C

tot

exceeds [V

g

+(V+V

f

)/N], that is when the secondary diode D1 starts to conduct.

+

2. At the end of the core reset, both switches (power

switch and secondary diode) are off. The primary

inductor L

P

together with C

tot

form a LC network.

C

tot

voltage (and thus the drain source voltage of

the power switch) oscillates around the input

voltage V

g

between a peak value (the initial level:

Vg

N

) and a valley value

Vg

effects being neglected. To benefit from the quasi

resonant mode, it is recommended to turn the power

switch on in the valley, where the drainsource

voltage is minimized. This naturally reduces the

dV/dt and switching losses to a minimum (in

practice, an appropriate delay inserted after the core

reset detection provides an effective method to

synchronize the power switch turn on with the valley

event). A simple look at Figure 7 shows that the

valley occurs at half the oscillation period.

Therefore, the delay

completion and the optimal turn on time is given by

the following equation:

LP

Once these delays are defined, it is about time to revise the

previous equations in order to include

The main parameters of interest are the average input and

output currents, the equivalent resistance and the switching

period. If we combine equations 24 and 13 that express I

P

as

a function of the input voltage, the inductor value and the

ONtime leads to:

V

V

the damping

t2

between the core reset

t2

Ctot

(eq. 25)

t1

and

t2

effects.

t1

LP

Ctot

Vg

Vg

V

N

ton

(eq. 26)

If (d

′

x T

S

) depicts the core reset time,

require to change (d

′

=1d) into:

t1

and

t2

times

d

1

d

t1

t2

TS

(eq. 27)

The inductor voltsecond balance approximation of

equation 8 still holds. However, it must be revised by

replacing d

′

(t) by its novel value as expressed by

equation (27):

1

V(LP)

d

Vg

d

t1

t2

TS

V

N

0

(eq. 28)

Rearranging equation (28), one can unveil the duty cycle

expression:

1

TS

(N

Vg)

The switching period is the sum of the ontime, the core

reset time (t

demag

),

t1

and

t2

:

TS

ton

tdemag

The time t

demag

can be easily deducted from the Figure 4

sketch. Since the core reset is the time necessary to discharge

the primary inductor from I

P

to zero with a (V+V

f

)/N slope,

it comes:

d

t1

t2

V

V

(eq. 29)

t1

t2

(eq. 30)

tdemag

LP

IP

V N

ton

N

Vg

V

(eq. 31)

Substitution of equation (31) into (eq. 30), leads to the

following expression where T

S

is a function of

t

on

:

[(N

TS

t1

t2

Vg)

V]

ton

N

(eq. 32)

Equation (15) that defines the average input current as a

function of the input voltage, the duty cycle, the inductor

value and the switching period, still holds. Substitution of

equation (29) into equation (15) leads to:

I1(t)

Vg

1

LP

t1

t2

TS

V

ton

V]

2

[(N

Vg)

(eq. 33)

Replacing T

S

by its equation 32 expression, it comes:

I1(t)

Vg

1

t1

t2

t1

t2

(N

Vg)

V

ton

V

V

ton

2

LP

[(N

Vg)

V]

(eq. 34)

Rearranging this equation, one can obtain:

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| AND8116 | Integrated Relay/Inductive Load Drivers for Industrial and Automotive Applications |

| AND8116D | Integrated Relay/Inductive Load Drivers for Industrial and Automotive Applications |

| AND8130 | Analog Switch Allows USB Switching at Low Voltages |

| AND8139 | Ultra-Low Voltage MiniGate Devices Solve 1.2 V Interface Problems |

| AND8139D | Ultra-Low Voltage MiniGate Devices Solve 1.2 V Interface Problems |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| AND8116 | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:Integrated Relay/Inductive Load Drivers for Industrial and Automotive Applications |

| AND8116D | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:Integrated Relay/Inductive Load Drivers for Industrial and Automotive Applications |

| AND8130 | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:Analog Switch Allows USB Switching at Low Voltages |

| AND8130/D | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:Analog Switch Allows USB Switching at Low Voltages |

| AND8139 | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:Ultra-Low Voltage MiniGate Devices Solve 1.2 V Interface Problems |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。