- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄295161 > BMR4532101/000 (ERICSSON POWER MODULES AB) DC-DC REG PWR SUPPLY MODULE PDF資料下載

參數(shù)資料

| 型號(hào): | BMR4532101/000 |

| 廠商: | ERICSSON POWER MODULES AB |

| 元件分類: | 電源模塊 |

| 英文描述: | DC-DC REG PWR SUPPLY MODULE |

| 封裝: | ROHS COMPLIANT, QUARTER-BRICK PACKAGE-16 |

| 文件頁數(shù): | 12/22頁 |

| 文件大小: | 2708K |

| 代理商: | BMR4532101/000 |

Ericsson Internal

PRODUCT SPECIFICATION

2 (4)

Prepared (also subject responsible if other)

No.

EAB/FC/P Jakub Brindell

1/1301- BMR 453 Uen

Approved

Checked

Date

Rev

Reference

EAB/FC/P Jakub Brindell

EJAKBRI

2009-01-23

D

General Information

Ordering Information

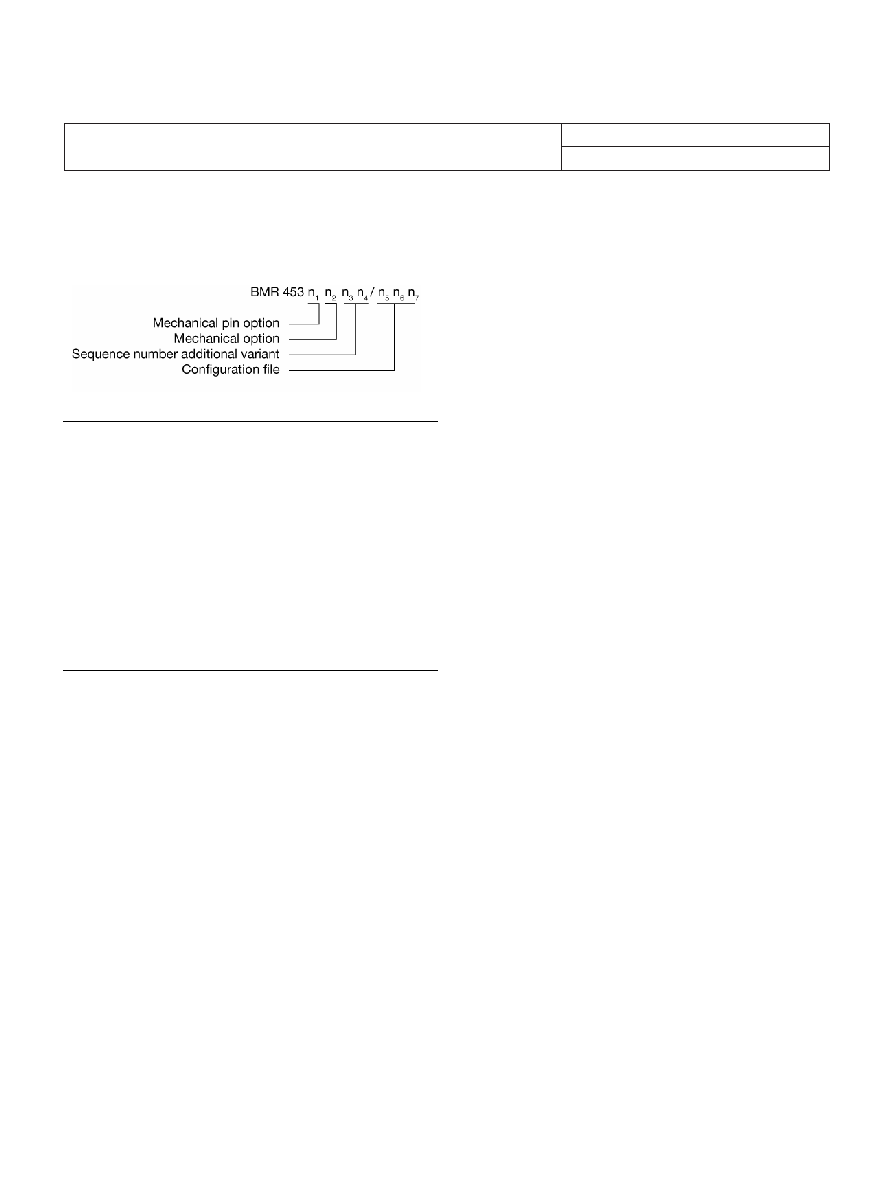

Number

Description

BMR453

n1

n2

n3 n4

n5 n6 n7

Default

0 = Standard pin length 5.33 mm

2 = Lead length 3.69 mm (cut)

3 = Lead length 4.57 mm (cut)

4 = Lead length 2.79 mm (cut)

5 = Lead length 2.79 mm stand off 6.7mm

0 = Open frame

1 = Baseplate

2 = Baseplate with GND-pin

00 = With digital interface

01 = Without digital interface

001 = 12V Default configuration variant

002 = 9V Default configuration variant

As an example an open frame, 3.69 mm pin length with digital interface with

configuration variant 002 would be BMR4532000/002.

Reliability

The Mean Time Between Failure (MTBF) is calculated at

full output power and an operating ambient temperature

(TA) of +40°C, which is a typical condition in Information

and Communication Technology (ICT) equipment. Different

methods could be used to calculate the predicted MTBF

and failure rate which may give different results. Ericsson

Power Modules currently uses Telcordia SR332.

Predicted MTBF for the series is:

-

1.1 million hours according to Telcordia SR332, issue

1, Black box technique.

Telcordia SR332 is a commonly used standard method

intended for reliability calculations in ICT equipment. The

parts count procedure used in this method was originally

modelled on the methods from MIL-HDBK-217F, Reliability

Predictions of Electronic Equipment. It assumes that no

reliability data is available on the actual units and devices

for which the predictions are to be made, i.e. all predictions

are based on generic reliability parameters.

Compatibility with RoHS requirements

The products are compatible with the relevant clauses and

requirements of the RoHS directive 2002/95/EC and have a

maximum concentration value of 0.1% by weight in

homogeneous materials for lead, mercury, hexavalent

chromium, PBB and PBDE and of 0.01% by weight in

homogeneous materials for cadmium.

Exemptions in the RoHS directive utilized in Ericsson

Power Modules products include:

-

Lead in high melting temperature type solder (used to

solder the die in semiconductor packages)

-

Lead in glass of electronics components and in

electronic ceramic parts (e.g. fill material in chip

resistors)

-

Lead as an alloying element in copper alloy containing

up to 4% lead by weight (used in connection pins made

of Brass)

Quality Statement

The products are designed and manufactured in an

industrial environment where quality systems and methods

like ISO 9000, 6σ (sigma), and SPC are intensively in use

to boost the continuous improvements strategy. Infant

mortality or early failures in the products are screened out

and they are subjected to an ATE-based final test.

Conservative design rules, design reviews and product

qualifications, plus the high competence of an engaged

work force, contribute to the high quality of our products.

Warranty

Warranty period and conditions are defined in Ericsson

AB’s General Terms and Conditions of Sale. Ericsson AB

does not make any other warranties, expressed or implied

including any warranty of merchantability, effects of product

configurations made by customers or fitness for a particular

purpose.

Ericsson AB 2008

The information and specifications in this technical

specification is believed to be correct at the time of

publication. However, no liability is accepted for

inaccuracies, printing errors or for any consequences

thereof. Ericsson AB reserves the right to change the

contents of this technical specification at any time without

prior notice.

E

BMR 453

DC/DC Converters, Input 36-75V, Output 33A/400 W

EN/LZT 146 395 R1C February 2009

Ericsson AB

Technical Specication

2

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| BNC-22 | CABLE TERMINATED, MALE, BNC CONNECTOR, CRIMP, PLUG |

| BNC-BHJ-13 | PANEL MOUNT, CABLE TERMINATED, FEMALE, BNC CONNECTOR, CRIMP, JACK |

| BP5081B15 | 1-OUTPUT DC-DC REG PWR SUPPLY MODULE |

| BPR-105 | POSITION, LINEAR SENSOR-DIFFUSE, 1-1mm, RECTANGULAR, THROUGH HOLE MOUNT |

| BPW17N | PHOTO TRANSISTOR DETECTOR |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| BMR4532103/010 | 制造商:Ericsson 功能描述:DCDC POWER MODULE 48V/5V, 50A |

| BMR4532106/013 | 制造商:Ericsson 功能描述:FULLY REGULATED INTERMEDIATE BUS CONVERTERS - Trays |

| BMR4532107/013 | 制造商:Ericsson 功能描述:- Trays 制造商:Ericsson 功能描述:Ericsson BMR4532107/013 |

| BMR4532200/001 | 制造商:Ericsson 功能描述:EIGHTH BRICK INTERMEDIATE BUS CONVERTER - Trays |

| BMR4533000/001 | 制造商:Ericsson 功能描述:- Trays |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。