- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄371822 > HIP6521EVAL1 (Intersil Corporation) PWM and Triple Linear Power Controller PDF資料下載

參數(shù)資料

| 型號(hào): | HIP6521EVAL1 |

| 廠商: | Intersil Corporation |

| 元件分類: | 基準(zhǔn)電壓源/電流源 |

| 英文描述: | PWM and Triple Linear Power Controller |

| 中文描述: | PWM和三線性功率控制器 |

| 文件頁數(shù): | 6/13頁 |

| 文件大小: | 154K |

| 代理商: | HIP6521EVAL1 |

6

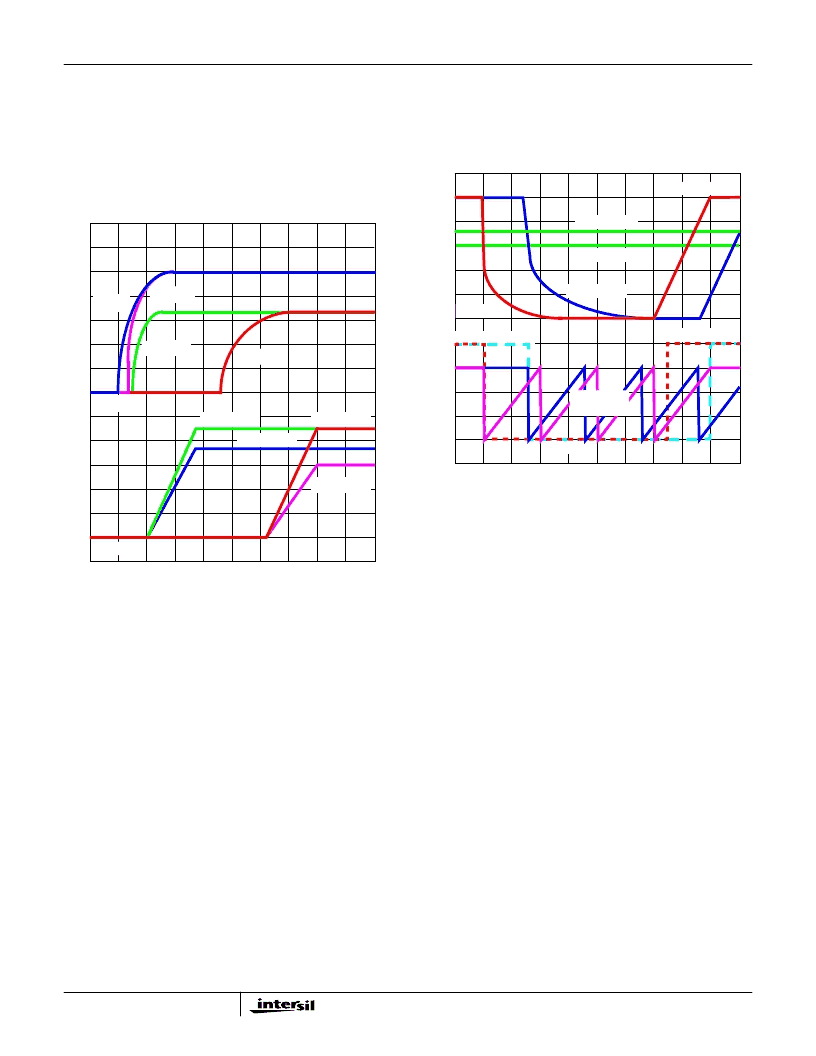

output voltage. As the internal soft-start voltage increases, the

pulse-width on the PHASE pin increases to reach its steady-

state duty cycle at time T2. At time T3, the 3.3V input supply

starts ramping up; as a result, V

OUT2

and V

OUT4

start ramping

up on the second attempt (approximately 3.25 SS cycles wait),

at time T4. During the interval between T4 and T5, the linear

controller error amplifiers’ references ramp to the final value

bringing all outputs within regulation limits.

Overcurrent Protection

All outputs are protected against excessive overcurrents.

The PWM controller uses the upper MOSFET’s

on-resistance, r

DS(ON)

to monitor the current for protection

against shorted output. All linear controllers monitor their

respective FB pins for undervoltage events to protect against

excessive currents.

A sustained overload (undervoltage on linears or overcurrent

on the PWM) on any output results in an independent

shutdown of the respective output, followed by subsequent

individual re-start attempts performed at an interval equivalent

to 3 soft-start intervals. Figure 2 describes the protection

feature. At time T0, an overcurrent event sensed across the

switching regulator’s upper MOSFET (r

DS(ON)

sensing)

triggers a shutdown of the V

OUT1

output. As a result, its

internal soft-start initiates a number of soft-start cycles. After a

three-cycle wait, the fourth soft-start initiates a ramp-up

attempt of the failed output, at time T2, bringing the output in

regulation at time T4.

To exemplify an UV event on one of the linears, at time T1,

the clock regulator (V

OUT2

) is also subjected to an

overcurrent event, resulting in an UV condition. Similarly,

after three soft-start periods, the fourth cycle initiates a

ramp-up of this linear output at time T3. One soft-start period

after T3, the linear output is within regulation limits. UV

glitches less than 1

μ

s (typically) in duration are ignored.

As overcurrent protection is performed on the synchronous

switcher regulator on a cycle-by-cycle basis, OC monitoring

is active as long as the regulator is operational. Since the

overcurrent protection on the linear regulators is performed

through undervoltage monitoring at the feedback pins (FB2,

FB3, and FB4), this feature is activated approximately 25%

into the soft-start interval (see Figure 2).

A resistor (R

OCSET

) programs the overcurrent trip level for

the PWM converter. As shown in Figure 3, the internal

40

μ

A current sink (I

OCSET

) develops a voltage across

R

OCSET

(V

SET

) that is referenced to V

IN

. The DRIVE

signal enables the overcurrent comparator (OCC). When

the voltage across the upper MOSFET (V

DS(ON)

) exceeds

V

SET

, the overcurrent comparator trips to set the

overcurrent latch. Both V

SET

and V

DS(ON)

are referenced

to V

IN

and a small capacitor across R

OCSET

helps V

OCSET

track the variations of V

IN

due to MOSFET switching. The

overcurrent function will trip at a peak inductor current

(I

PEAK)

determined by:

×

DS ON

)

The OC trip point varies with MOSFET’s r

DS(ON)

temperature variations. To avoid overcurrent tripping in the

normal operating load range, determine the R

OCSET

resistor from the equation above with:

FIGURE 1. SOFT-START INTERVAL

0V

0V

TIME

+5V

SB

(0.5V/DIV)

V

OUT2

(2.5V)

V

OUT4

(1.5V)

T1

T2

T3

T0

T4

(1V/DIV)

+3.3V

IN

+5V

DUAL

+3.3V

DUAL

V

OUT3

(1.8V)

V

OUT1

(2.5V)

T5

FIGURE2. OVERCURRENT/UNDERVOLTAGEPROTECTION

RESPONSE

0V

TIME

(0.5V/DIV.)

V

OUT3

(1.8V)

V

OUT2

(2.5V)

T1

T2

T3

T0

V

OUT4

(1.5V)

V

OUT1

(2.5V)

UV MONITORING

INACTIVE

SOFT-START

FUNCTION

ACTIVE

T4

I

PEAK

=

I

-------------r

R

OCSET

HIP6521

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HIP6602BCRZ-T | Dual Channel Synchronous Rectified Buck MOSFET Driver |

| HIP6602BCRZA | Dual Channel Synchronous Rectified Buck MOSFET Driver |

| HIP6602BCRZA-T | Dual Channel Synchronous Rectified Buck MOSFET Driver |

| HIP6602B | Dual Channel Synchronous Rectified Buck MOSFET Driver |

| HIP6602BCBZ-T | Dual Channel Synchronous Rectified Buck MOSFET Driver |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HIP6601 | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:Synchronous-Rectified Buck MOSFET Drivers |

| HIP6601_04 | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:Synchronous-Rectified Buck MOSFET Drivers |

| HIP6601A | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:Synchronous Rectified Buck MOSFET Drivers |

| HIP6601ACB | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:Synchronous Rectified Buck MOSFET Drivers |

| HIP6601ACB-T | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。