- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄359125 > MA4BPS101 PIN Diode Chips with Offset Bond Pads PDF資料下載

參數(shù)資料

| 型號: | MA4BPS101 |

| 英文描述: | PIN Diode Chips with Offset Bond Pads |

| 中文描述: | PIN二極管芯片的邦德片偏移 |

| 文件頁數(shù): | 2/4頁 |

| 文件大小: | 83K |

| 代理商: | MA4BPS101 |

PIN Diode Chips With Offset Bond Pads

MA4BPS101, MA4BPS201, MA4BPS301

M/A-COM Division of AMP Incorporated

Q

North America: Tel. (800) 366-2266, Fax (800) 618-8883

Q

Asia/Pacific: Tel.+85 2 2111 8088, Fax +85 2 2111 8087

Q

Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

www.macom.com

AMP and Connecting at a Higher Level are trademarks.

Specifications subject to change without notice.

V2.01

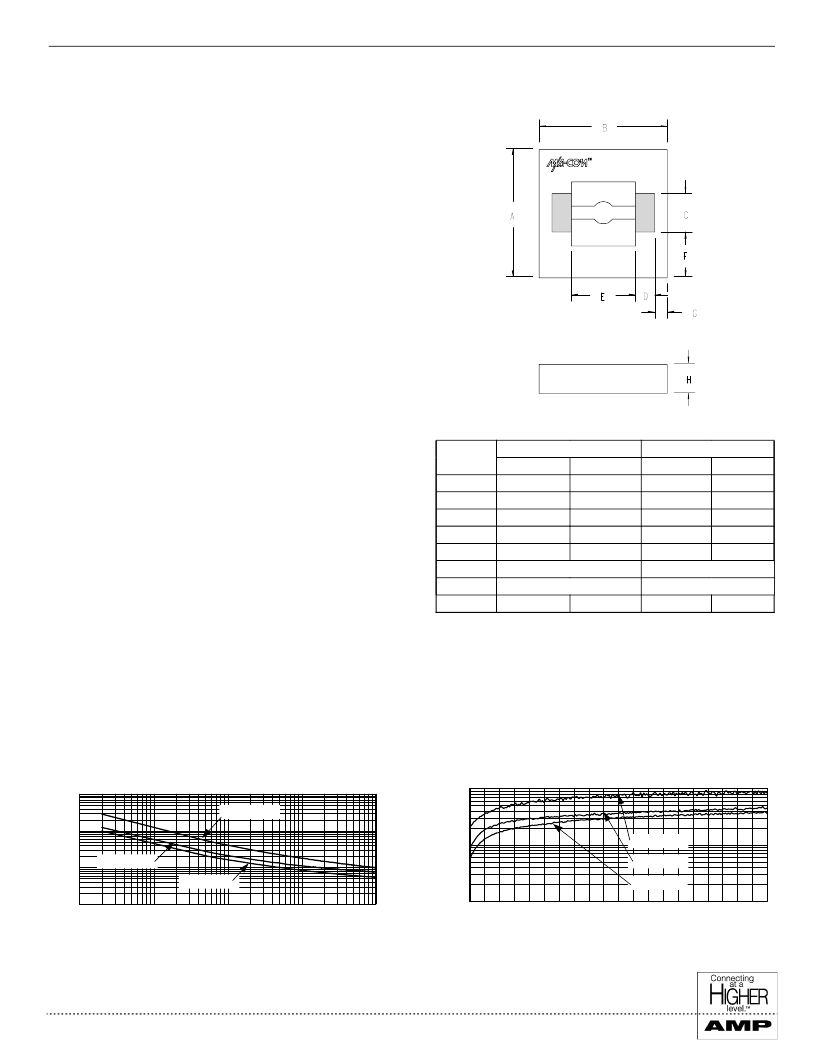

Chip Outline Drawing (ODS-1244)

1,000

10,000

100,000

0.0

2.0

4.0

6.0

8.0

10.0

Re v e r s e Vol t a ge ( Vol t s )

Typical Resistance Curves

Series Resistance vs. Forward Current at 1 GHz

Parallel Resistance vs. Reverse Voltage at 1 GHz

Hanlding and Mounting Information

Handling

All semiconductor dice should be handled with care to avoid

damage or contamination. For an individual die, the use of

plastic tipped tweezers or vacuum pick-up tool is recommended.

When using automatic pick and place, abrasion and mechanical

shock should be minimized.

Mounting

The dice have Ti-Pt-Au back metal, with a final gold thickness

of 0.1 micron. They can be die mounted with a gold-tin eutectic

solder preform or conductive epoxy. The mounting surface

must be clean and flat.

Eutectic Die Attachment

An 80/20 gold-tin eutectic solder preform is recommended with

a work surface temperature of 255

°

C and a tool tip temperature

of 265

°

C. When hot gas is applied, the tool tip temperature

should be 290

°

C. The chip should not be exposed to tempera-

tures greater than 320

°

C for more than 20 seconds. No more

than three seconds should be required for attachment.

Epoxy Die Attachment

A minimum amount of epoxy should be used. A thin epoxy

fillet should be visible around the perimeter of the chip after

placement. Cure epoxy per manufacturer’s schedule.

Wire Bonding

The two bond pads on these die have a Ti-Pt-Au metalization

scheme, with a final gold thickness of 2.5 microns. The pads are

75 x 150 microns; up to two wires or a 100 micron wide ribbon

can be bonded to each pad. Thermosonic wedge wire bonding of

0.001” diameter gold wire is recommended with a stage temper-

ature of 150

°

C and a force of 25 to 40 grams. Ultrasonic energy

should be adjusted to the minimum required.

INCHES

MILLIMETERS

MIN

0.480

0.480

0.140

0.065

0.240

0.180 Ref.

0.050 Ref.

0.110

DIM

A

B

C

D

E

F

G

H

MIN

0.019

0.019

0.0055

0.0026

0.0094

MAX

0.0213

0.0213

0.0063

0.0033

0.0102

MAX

0.540

0.540

0.160

0.085

0.260

0.007 Ref.

0.002 Ref.

0.0043

0.0055

0.140

Notes:

1. Bond pad material: 2.5 micron thick gold.

2. Shaded areas indicate wire bonding pads

3. Backside metal: 0.1 micron thick gold.

0.1

1.0

10.0

100.0

0.0

0.1

1.0

10.0

100.0

F o r w a r d C u r r e n t ( m A )

S

MA4BPS101

MA4BPS201

MA4BPS301

MA4BPS101

MA4BPS201

MA4BPS301

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MA4E1339SERIES | Silicon Medium Barrier Schottky Diode |

| MA4E185-276 | Stripline Packaged Schottky Mixer Diodes |

| MA4E185-276 | STRIPLINE PACKAGED SCHOTTKY MIXER DIODES |

| MA4E2054 | Surface Mount Low Barrier X-Band Schottky Diode |

| MA4EX370L-1225 | Low Cost Silicon Double Balanced HMIC Mixer 3.0 - 4.0 GHz |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MA4BPS201 | 制造商:M/A-COM Technology Solutions 功能描述:PIN ATTENUATOR/SWIT 70V 2PIN ODS-1244 - Bulk |

| MA4BPS301 | 制造商:M/A-COM Technology Solutions 功能描述:PIN ATTENUATOR/SWIT 70V 2PIN ODS-1244 - Bulk |

| MA4C5 | 制造商:EDAL 制造商全稱:EDAL 功能描述:SILICON GENERAL PURPOSE 3.0 AMP DIODES |

| MA4CM00 | 制造商:TE Connectivity 功能描述: |

| MA4CM01 | 制造商:TE Connectivity 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。