- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄359125 > MA4SPS502 Surface Mount Monolithic PIN Diode Chip PDF資料下載

參數(shù)資料

| 型號(hào): | MA4SPS502 |

| 英文描述: | Surface Mount Monolithic PIN Diode Chip |

| 中文描述: | 表面貼裝芯片單片PIN二極管 |

| 文件頁(yè)數(shù): | 2/3頁(yè) |

| 文件大小: | 126K |

| 代理商: | MA4SPS502 |

Surface Mount Monolithic PIN Diode Chip

MA4SPS502 SurMount

TM

Series

Specifications subject to change without notice.

n

North America:

Tel. (800) 366-2266

n

Asia/Pacific:

Tel.+81-44-844-8296, Fax +81-44-844-8298

n

Europe:

Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

Visit www.macom.com for additional data sheets and product information.

Electrical Specifications: @ 25 °C

Symbol

Test Conditions

Units

Min.

Typ.

Max.

C

T

-40 Volts, 1 MHz

pF

0.140

0.200

C

T

-40 Volts, 1 GHz

pF

0.090

R

S

100 mA, 100 MHz

1.4

R

S

20 mA, 100 MHz

2.4

V

F

100 mA

V

1.24

1.50

V

F

10 mA

V

0.87

1.00

V

R

10

μ

A

V

-300

-330

I

R

-300 V

μ

A

10

I

R

-40 V

nA

8

R

θ

JL

Steady state

°C/W

75

T

L

+10 mA / -6 mA measured at 90% voltage

μs

2.8

2

Handling Procedures

All semiconductor chips should be handled with care to avoid

damage or contamination from perspiration and skin oils. The

use of plastic tipped tweezers or vacuum pickups is strongly

recommended for individual components. Bulk handling should

insure that abrasion and mechanical shock are minimized.

Bonding Techniques

Attachment to a circuit board is made simple through the use of

surface mount technology. Mounting pads are conveniently

located on the bottom surface of these diodes and are removed

from the active junction locations. These devices are well suited

for solder attachment onto hard and soft substrates. The use of

80/20 Au/Sn and 60/40 Sn/Pb solder is recommended, with an

equal temperature profile across the contacts. Conductive epoxy

paste for attachment may also be used.

When soldering these devices to a hard substrate, hot gas die

bonding is preferred. We recommend utilizing a vacuum tip and

a force of 60 to 100 grams applied normal to the top surface of

the device. When soldering to soft substrates, it is recommended

to use a lead-tin interface at the circuit board mounting pads.

Position the die so that its mounting pads are aligned with the

circuit board’s mounting pads and reflow the solder by heating

the circuit trace near the mounting pad while applying 60 to 100

grams of force perpendicular to the top surface of the die.

Since the HMIC glass is transparent, the edges of the mounting

pads closest to each other can be visually inspected through the

die after attach is completed.

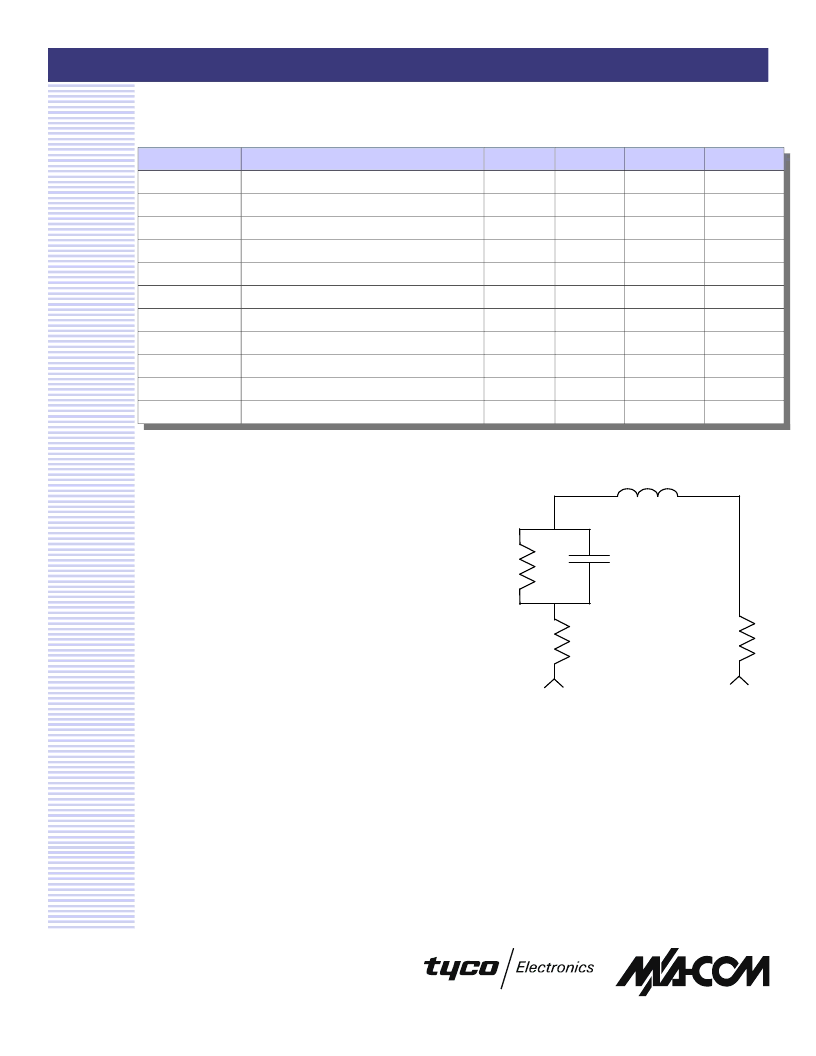

Functional Schematic

1

Rp

Cp

Ls

Rvia

Rvia

+

-

1. Rs = 2 * Rvia + Rp

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MA4SW424B-1 | Monolithic SP4T PIN Diode Switch With Integrated Bias Network |

| MA4VAT904-1061T | High IIP3 PIN Diode Variable Attenuator (0.80-1.0 GHz) |

| MA505 | ECM Surface Mount Crystal |

| MA838 | SINGLE PHASE PULSE WIDTH MODULATION WAVEFORM GENERATOR |

| MAADSS0010 | Digital Attenuator, 5-Bit, 31 dB (400 - 2500 MHz) |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MA4SPS502_1 | 制造商:MA-COM 制造商全稱:M/A-COM Technology Solutions, Inc. 功能描述:SURMOUNT PIN Diode |

| MA4SPS502-T | 制造商:M/A-COM Technology Solutions 功能描述:SURMOUNT PIN DIODE - LOW RC PRODUCT - Tape and Reel |

| MA4SPS552 | 制造商:M/A-COM Technology Solutions 功能描述:SURFACE MOUNT MONOLITHIC PIN DIODE CHIP - Gel-pak, waffle pack, wafer, diced wafer on film 制造商:M/A-COM Technology Solutions 功能描述:Diode PIN Attenuator/Switch 200V Die |

| MA4SPS552-T | 制造商:MA-COM 制造商全稱:M/A-COM Technology Solutions, Inc. 功能描述:SURMOUNTTM PIN Diode |

| MA4SPS552-W | 制造商:MA-COM 制造商全稱:M/A-COM Technology Solutions, Inc. 功能描述:SURMOUNTTM PIN Diode |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。