- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄359155 > MCZ33977EG (飛思卡爾半導體(中國)有限公司) Single Gauge Driver PDF資料下載

參數(shù)資料

| 型號: | MCZ33977EG |

| 廠商: | 飛思卡爾半導體(中國)有限公司 |

| 英文描述: | Single Gauge Driver |

| 中文描述: | 單表驅(qū)動 |

| 文件頁數(shù): | 17/37頁 |

| 文件大小: | 402K |

| 代理商: | MCZ33977EG |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁當前第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁

Analog Integrated Circuit Device Data

Freescale Semiconductor

17

33977

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

POINTER DECELERATION

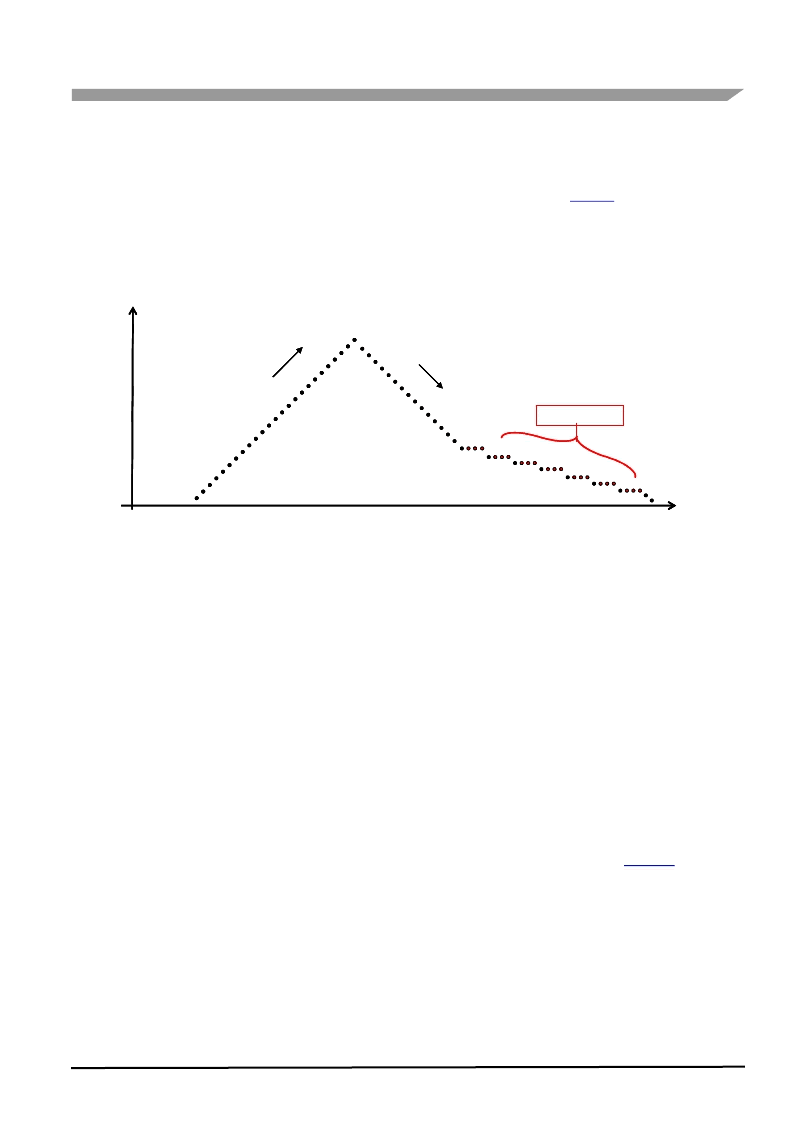

Constant acceleration and deceleration of the pointer

produces relatively choppy movements when compared to

those of an air core gauge. Modification of the velocity

position ramp during deceleration can create the desired

damped movement. This modification is accomplished in the

33977 by adding repetitive steps at several of the last velocity

position step values as the pointer decelerates. The default

movement in the 33977 uses this ramp modification feature.

An example is illustrated in

Figure 9

. If the maximum

acceleration and deceleration of the pointer is desired, the

repetitive steps can be disabled by writing Logic [1] to the

PECCR bit PE5.

.

Figure 9. Deceleration Ramp

RETURN TO ZERO CALIBRATION

Many stepper motor applications require [

that

deleted as

PV] the IC detect when the stepper motor stalls after

commanded to return to the zero position for calibration

purposes. In instrumentation applications, the stalling occurs

when the pointer hits the end stop on the gauge bezel,

[

which is

deleted as PV] usually at the zero position. It is

important to know [

that

PV] when the pointer reaches the end

stop, it immediately stops without bouncing away. The 33977

device provides the ability to automatically and independently

return the pointer to the zero position via the RTZR and

RTZCR SPI commands. An automatic RTZ is initiated, using

the RZ1 and RZ2 bits, provided the RZ4 is Logic [1]. During

an RTZ event, all commands related to the gauge being

returned are ignored until the pointer has successfully

zeroed, or the RTZR bit RZ1 is written to disable the event.

Once an RTZ event is initiated, the device reports back via

the SO pin an RTZ event is underway.

The RTZCR command is used to set the RTZ pointer

speed, choose an appropriate blanking time, and preload the

integration accumulator with an appropriate offset. On

reaching the end stop, the device reports back to the

microcontroller via the status message [

that

PV] the RTZ was

successful. The RTZ automatically disables, [

that will

PV]

allowing other commands to be valid. In the event the master

determines an RTZ sequence is not working properly, for

example, the RTZ taking too long; it can disable the

command via the RTZR bit RZ1. [Altered for better read flow]

RTZCR bits RC10:RC5 are written to preload the

accumulator with a predetermined value assuring accurate

pointer stall detection. This preloaded value can be

determined during application development by disabling the

automatic shutdown feature of the device with the RTZR bit

RZ4. This operating mode allows the master to monitor the

RTZ event, using the accumulator information available via

the SO if the device is configured to provide the RTZ

Accumulator Status. The unconditional RTZ event can be

turned OFF using the RTZR bit RZ1.

If the Position 0 location bit, RZ2, is in the default Logic [0]

mode, then during an RTZ event the pointer is returned

counterclockwise (CCW) using full steps at a constant speed

determined by the RTZCR RC3:RC0 and RC12:RC11 bits

written during RTZ configuration, see

Figure 10

. Full steps

are used during an RTZ so only coil of the motor is being

driven at any time. The coil not being driven is used to

determine if the pointer is moving. If the pointer is moving, the

flux present in the non-driven coil is processed by integrating

the back EMF signal present on the opened pin of the coil

while applying a fixed potential to the other end.

24

23

22

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

20

21

22

23

24

= 0

Position

Position

Microsteps

Hold Counts

Figure 8. Dec eleration Ramp

V elocity

Acceeae

Deceeae

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MCZ33989EG | System Basis Chip with High-Speed CAN Transceiver |

| MCZ33990EF | Enhanced Class B Serial Transceiver |

| MCZ33991EG | Gauge Driver Integrated Circuit |

| MCZ33993EW | Multiple Switch Detection Interface |

| MCZ33996EK | 16-Output Switch with SPI Control |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MCZ33977EG | 制造商:Freescale Semiconductor 功能描述:IC STEPPER MOTOR GAUGE DRIVER SPI |

| MCZ33977EGR2 | 功能描述:馬達/運動/點火控制器和驅(qū)動器 SINGLE GAUGE DR. LG. PTR RoHS:否 制造商:STMicroelectronics 產(chǎn)品:Stepper Motor Controllers / Drivers 類型:2 Phase Stepper Motor Driver 工作電源電壓:8 V to 45 V 電源電流:0.5 mA 工作溫度:- 25 C to + 125 C 安裝風格:SMD/SMT 封裝 / 箱體:HTSSOP-28 封裝:Tube |

| MCZ33989EG | 功能描述:網(wǎng)絡控制器與處理器 IC SBC-HS RoHS:否 制造商:Micrel 產(chǎn)品:Controller Area Network (CAN) 收發(fā)器數(shù)量: 數(shù)據(jù)速率: 電源電流(最大值):595 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:PBGA-400 封裝:Tray |

| MCZ33989EG | 制造商:Freescale Semiconductor 功能描述:IC SYSTEM BASIS W/CAN TRANCEIVER |

| MCZ33989EGR2 | 功能描述:網(wǎng)絡控制器與處理器 IC SBC-HS RoHS:否 制造商:Micrel 產(chǎn)品:Controller Area Network (CAN) 收發(fā)器數(shù)量: 數(shù)據(jù)速率: 電源電流(最大值):595 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:PBGA-400 封裝:Tray |

發(fā)布緊急采購,3分鐘左右您將得到回復。