- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄371181 > TDA3661AT (NXP SEMICONDUCTORS) Very low dropout voltage/quiescent current adjustable voltage regulator PDF資料下載

參數(shù)資料

| 型號: | TDA3661AT |

| 廠商: | NXP SEMICONDUCTORS |

| 元件分類: | 基準(zhǔn)電壓源/電流源 |

| 英文描述: | Very low dropout voltage/quiescent current adjustable voltage regulator |

| 中文描述: | 1.5 V-45 V ADJUSTABLE POSITIVE LDO REGULATOR, 0.3 V DROPOUT, PDSO8 |

| 封裝: | 3.90 MM, PLASTIC, SOP-8 |

| 文件頁數(shù): | 12/16頁 |

| 文件大小: | 88K |

| 代理商: | TDA3661AT |

9397 750 15049

Koninklijke Philips Electronics N.V. 2005. All rights reserved.

Product data sheet

Rev. 05 — 28 June 2005

12 of 16

Philips Semiconductors

TDA3661

Very low dropout voltage/quiescent current voltage regulator

–

smaller than 1.27 mm, the footprint longitudinal axis

must

be parallel to the

transport direction of the printed-circuit board.

The footprint must incorporate solder thieves at the downstream end.

For packages with leads on four sides, the footprint must be placed at a 45

°

angle to

the transport direction of the printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must be fixed with a droplet of

adhesive. The adhesive can be applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the adhesive is cured.

Typical dwell time of the leads in the wave ranges from 3 seconds to 4 seconds at 250

°

C

or 265

°

C, depending on solder material applied, SnPb or Pb-free respectively.

A mildly-activated flux will eliminate the need for removal of corrosive residues in most

applications.

14.4 Manual soldering

Fix the component by first soldering two diagonally-opposite end leads. Use a low voltage

(24 V or less) soldering iron applied to the flat part of the lead. Contact time must be

limited to 10 seconds at up to 300

°

C.

When using a dedicated tool, all other leads can be soldered in one operation within

2 seconds to 5 seconds between 270

°

C and 320

°

C.

14.5 Package related soldering information

[1]

For more detailed information on the BGA packages refer to the (LF)BGA Application Note(AN01026);

order a copy from your Philips Semiconductors sales office.

[2]

All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the

maximum temperature (with respect to time) and body size of the package, there is a risk that internal or

external package cracks may occur due to vaporization of the moisture in them (the so called popcorn

effect). For details, refer to the Drypack information in the Data Handbook IC26; Integrated Circuit

Packages; Section: Packing Methods

[3]

These transparent plastic packages are extremely sensitive to reflow soldering conditions and must on no

account be processed through more than one soldering cycle or subjected to infrared reflow soldering with

peak temperature exceeding 217

°

C

±

10

°

C measured in the atmosphere of the reflow oven. The package

body peak temperature must be kept as low as possible.

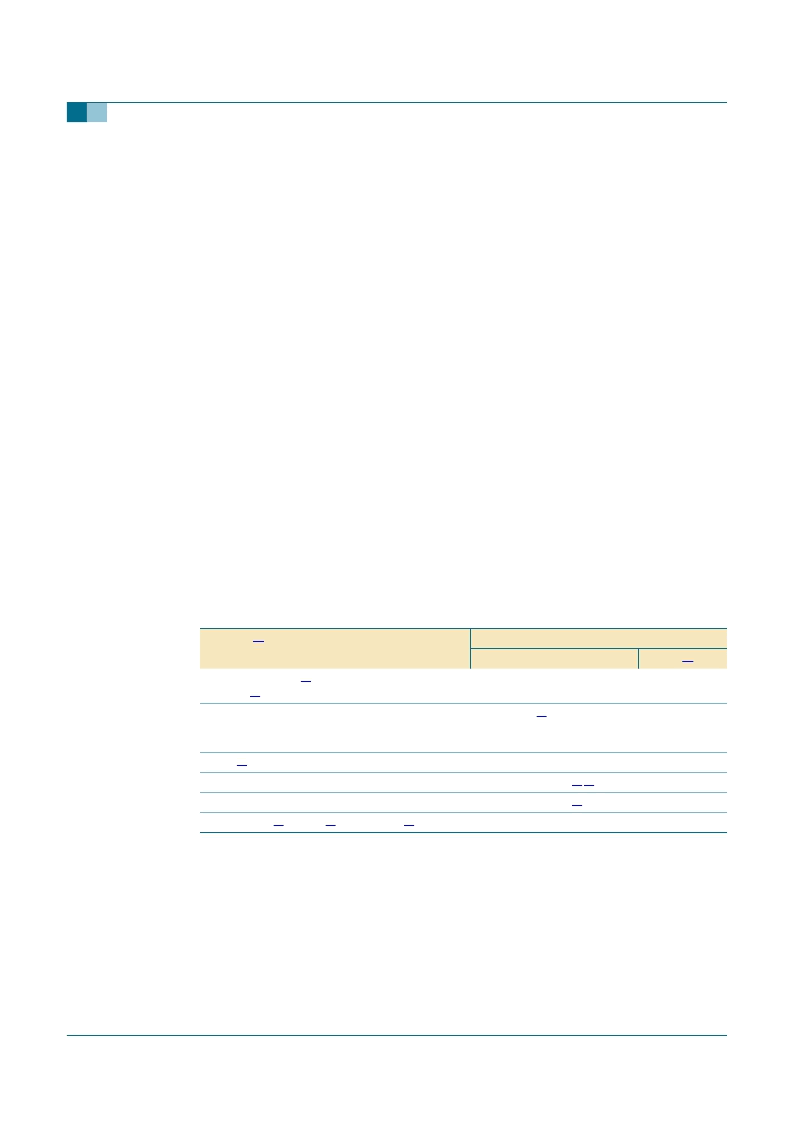

Table 9:

Package

[1]

Suitability of surface mount IC packages for wave and reflow soldering methods

Soldering method

Wave

BGA, HTSSON..T

[3]

, LBGA, LFBGA, SQFP,

SSOP..T

[3]

, TFBGA, VFBGA, XSON

DHVQFN, HBCC, HBGA, HLQFP, HSO, HSOP,

HSQFP, HSSON, HTQFP, HTSSOP, HVQFN,

HVSON, SMS

PLCC

[5]

, SO, SOJ

LQFP, QFP, TQFP

SSOP, TSSOP, VSO, VSSOP

CWQCCN..L

[8]

, PMFP

[9]

, WQCCN..L

[8]

Reflow

[2]

suitable

not suitable

not suitable

[4]

suitable

suitable

not recommended

[5] [6]

not recommended

[7]

not suitable

suitable

suitable

suitable

not suitable

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| TDA3661T | Very low dropout voltage/quiescent current adjustable voltage regulator |

| TDA3825 | 50 AMP LATCHING POWER RELAY |

| TDA3845 | 50 AMP LATCHING POWER RELAY |

| TDA3845T | 50 AMP LATCHING POWER RELAY |

| TDA4470-MFLG3 | Multistandard Video-IF and Quasi Parallel Sound Processing |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| TDA3661AT/N1,118 | 功能描述:低壓差穩(wěn)壓器 - LDO TDA3661AT/SO8/REEL13//N1 RoHS:否 制造商:Texas Instruments 最大輸入電壓:36 V 輸出電壓:1.4 V to 20.5 V 回動電壓(最大值):307 mV 輸出電流:1 A 負載調(diào)節(jié):0.3 % 輸出端數(shù)量: 輸出類型:Fixed 最大工作溫度:+ 125 C 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:VQFN-20 |

| TDA3661T | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Very low dropout voltage/quiescent current adjustable voltage regulator |

| TDA3662 | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Very low dropout voltage/quiescent current 3.0 V voltage regulator |

| TDA3662AT | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Very low dropout voltage/quiescent current 3.0 V voltage regulator |

| TDA3663 | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Very low dropout voltage/quiescent current 3.3 V voltage regulator |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。