- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄367565 > LM4766TF AUDIO AMPLIFIER|DUAL|BIPOLAR|ZIP|15PIN|PLASTIC PDF資料下載

參數(shù)資料

| 型號: | LM4766TF |

| 元件分類: | 音頻放大器 |

| 英文描述: | AUDIO AMPLIFIER|DUAL|BIPOLAR|ZIP|15PIN|PLASTIC |

| 中文描述: | 音頻放大器|雙|雙極|郵政編碼| 15針|塑料 |

| 文件頁數(shù): | 11/15頁 |

| 文件大小: | 480K |

| 代理商: | LM4766TF |

Application Information

(Continued)

pulled out of mute mode. Taking into account supply line fluc-

tuations, it is a good idea to pull out 1mA per mute pin or

2 mA total if both pins are tied together.

UNDER-VOLTAGE PROTECTION

Upon system power-up, the under-voltage protection cir-

cuitry allows the power supplies and their corresponding ca-

pacitors to come up close to their full values before turning

on the LM4766 such that no DC output spikes occur. Upon

turn-off, the output of the LM4766 is brought to ground be-

fore the power supplies such that no transients occur at

power-down.

OVER-VOLTAGE PROTECTION

The LM4766 contains over-voltage protection circuitry that

limits the output current to approximately 4.0A

while also

providing voltage clamping, though not through internal

clamping diodes. The clamping effect is quite the same,

however, the output transistors are designed to work alter-

nately by sinking large current spikes.

SPiKe PROTECTION

The

LM4766

temperature stressing of the power transistor array. The Safe

Operating graph in the

Typical Performance Characteris-

tics

section shows the area of device operation where

SPiKe

Protection Circuitry is not enabled. The waveform to

the right of the SOA graph exemplifies how the dynamic pro-

tection will cause waveform distortion when enabled. Please

refer to AN-898 for more detailed information.

is

protected

from

instantaneous

peak-

THERMAL PROTECTION

The LM4766 has a sophisticated thermal protection scheme

to prevent long-term thermal stress of the device. When the

temperature on the die reaches 165C, the LM4766 shuts

down. It starts operating again when the die temperature

drops to about 155C, but if the temperature again begins to

rise, shutdown will occur again at 165C. Therefore, the de-

vice is allowed to heat up to a relatively high temperature if

the fault condition is temporary, but a sustained fault will

cause the device to cycle in a Schmitt Trigger fashion be-

tween the thermal shutdown temperature limits of 165C and

155C. This greatly reduces the stress imposed on the IC by

thermal cycling, which in turn improves its reliability under

sustained fault conditions.

Since the die temperature is directly dependent upon the

heat sink used, the heat sink should be chosen such that

thermal shutdown will not be reached during normal opera-

tion. Using the best heat sink possible within the cost and

space constraints of the system will improve the long-term

reliability of any power semiconductor device, as discussed

in the

Determining the Correct Heat Sink

Section.

DETERMlNlNG MAXIMUM POWER DISSIPATION

Power dissipation within the integrated circuit package is a

very important parameter requiring a thorough understand-

ing if optimum power output is to be obtained. An incorrect

maximum power dissipation calculation may result in inad-

equate heat sinking causing thermal shutdown and thus lim-

iting the output power.

Equation (1)exemplifies the theoretical maximum power dis-

sipation point of each amplifier where V

CC

is the total supply

voltage.

P

DMAX

= V

CC2

/2

π

2

R

L

(1)

Thus by knowing the total supply voltage and rated output

load, the maximum power dissipation point can be calcu-

lated. The package dissipation is twice the number which re-

sults from Equation (1)since there are two amplifiers in each

LM4766. Refer to the graphs of Power Dissipation versus

Output Power in the

Typical Performance Characteristics

section which show the actual full range of power dissipation

not just the maximum theoretical point that results from

Equation (1)

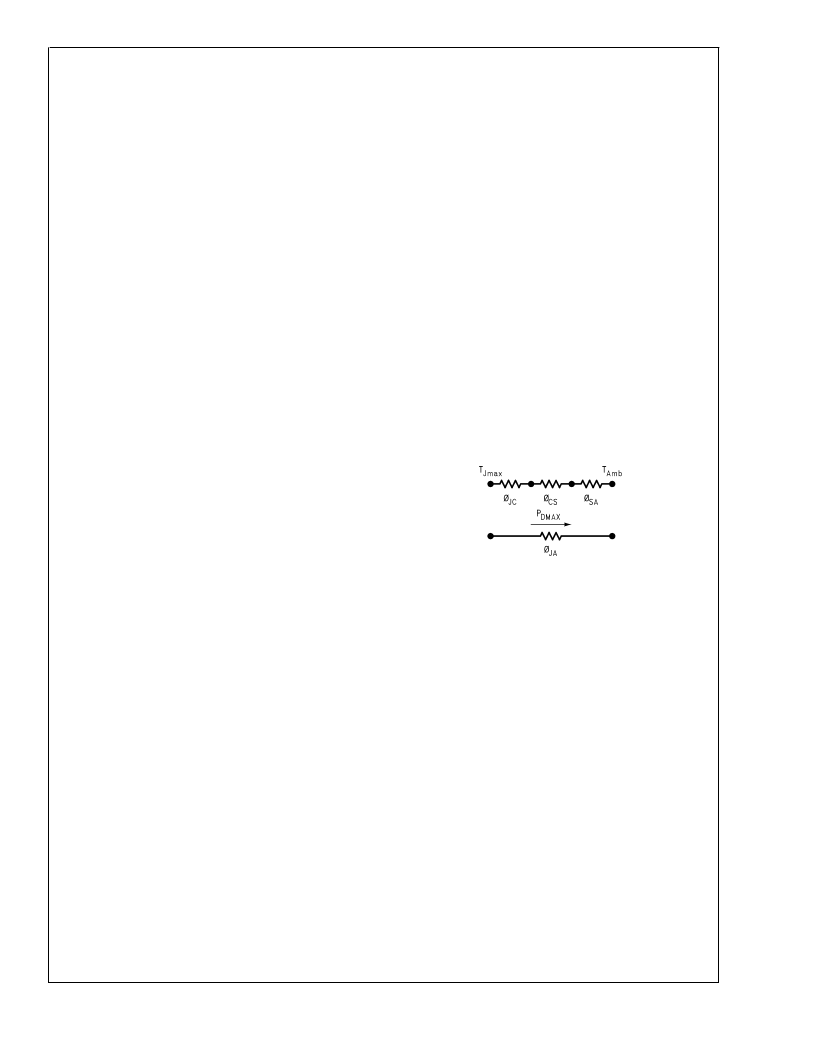

DETERMINING THE CORRECT HEAT SINK

The choice of a heat sink for a high-power audio amplifier is

made entirely to keep the die temperature at a level such

that the thermal protection circuitry does not operate under

normal circumstances.

The thermal resistance from the die (junction) to the outside

air (ambient) is a combination of three thermal resistances,

θ

,

θ

, and

θ

. In addition, the thermal resistance,

θ

(junction to case), of the LM4766T is 1C/W. Using Thermal-

loy Thermacote thermal compound, the thermal resistance,

θ

(case to sink), is about 0.2C/W. Since convection heat

flow (power dissipation) is analogous to current flow, thermal

resistance is analogous to electrical resistance, and tem-

perature drops are analogous to voltage drops, the power

dissipation out of the LM4766 is equal to the following:

P

DMAX

= (T

JMAX

T

AMB

)/

θ

JA

where T

JMAX

= 150C, T

AMB

is the system ambient tempera-

ture and

JA

=

θ

JC

+

θ

CS

θ

SA

.

(2)

Once the maximum package power dissipation has been

calculated using Equation (1) the maximum thermal resis-

tance,

θ

, (heat sink to ambient) in C/W for a heat sink can

be calculated. This calculation is made using Equation (3)

which is derived by solving for

θ

SA

in Equation (2)

θ

SA

= [(T

JMAX

T

AMB

)P

DMAX

(

θ

JC

+

θ

CS

)]/P

DMAX

Again it must be noted that the value of

θ

is dependent

upon the system designer’s amplifier requirements. If the

ambient temperature that the audio amplifier is to be working

under is higher than 25C, then the thermal resistance for the

heat sink, given all other things are equal, will need to be

smaller.

(3)

SUPPLY BYPASSING

The LM4766 has excellent power supply rejection and does

not require a regulated supply. However, to improve system

performance as well as eliminate possible oscillations, the

LM4766 should have its supply leads bypassed with

low-inductance capacitors having short leads that are lo-

cated close to the package terminals. Inadequate power

supply bypassing will manifest itself by a low frequency oscil-

lation known as “motorboating” or by high frequency insta-

bilities. These instabilities can be eliminated through multiple

bypassing utilizing a large tantalum or electrolytic capacitor

(10μF or larger) which is used to absorb low frequency varia-

tions and a small ceramic capacitor (0.1μF) to prevent any

high frequency feedback through the power supply lines.

DS100928-52

L

www.national.com

11

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| LM4836MTEX | Dual Audio Amplifier |

| LM4836MTX | Dual Audio Amplifier |

| LM4851IBL-1 | Amplifier. Other |

| LM4854LD | AUDIO AMPLIFIER|DUAL|LLCC|14PIN|CERAMIC |

| LM4854MM | AUDIO AMPLIFIER|DUAL|TSSOP|10PIN|PLASTIC |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| LM4766TF/NOPB | 功能描述:音頻放大器 RoHS:否 制造商:STMicroelectronics 產(chǎn)品:General Purpose Audio Amplifiers 輸出類型:Digital 輸出功率: THD + 噪聲: 工作電源電壓:3.3 V 電源電流: 最大功率耗散: 最大工作溫度: 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:TQFP-64 封裝:Reel |

| LM4766TF/NOPB | 制造商:Texas Instruments 功能描述:Audio Power Amplifier IC |

| LM476-S | 功能描述:基本/快動開關(guān) Foot Switch RoHS:否 制造商:Omron Electronics 觸點(diǎn)形式:SPDT 執(zhí)行器:Lever 電流額定值:5 A 電壓額定值 AC:250 V 電壓額定值 DC:30 V 功率額定值: 工作力:120 g IP 等級:IP 67 NEMA 額定值: 端接類型:Wire 安裝:Panel |

| LM4780 | 制造商:NSC 制造商全稱:National Semiconductor 功能描述:Audio Power Amplifier Series Stereo 60W, Mono 120W Audio Power Amplifier with Mute |

| LM4780TA | 功能描述:音頻放大器 RoHS:否 制造商:STMicroelectronics 產(chǎn)品:General Purpose Audio Amplifiers 輸出類型:Digital 輸出功率: THD + 噪聲: 工作電源電壓:3.3 V 電源電流: 最大功率耗散: 最大工作溫度: 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:TQFP-64 封裝:Reel |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。