- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄367641 > P12763EJ1V0AN00 MCU CMOS 28 LD 20MHZ 8K FLASH, -40C to +85C, 28-SPDIP, TUBE PDF資料下載

參數(shù)資料

| 型號: | P12763EJ1V0AN00 |

| 英文描述: | MCU CMOS 28 LD 20MHZ 8K FLASH, -40C to +85C, 28-SPDIP, TUBE |

| 中文描述: | uPC8119T和uPC8120T可變增益高頻硅單片放大器的AGC移動(dòng)通信股 |

| 文件頁數(shù): | 13/19頁 |

| 文件大小: | 159K |

| 代理商: | P12763EJ1V0AN00 |

13

Note

In the example of mounting on a printed circuit board in the test circuit in the Data Sheet, more than one

inductor L1 for output matching is connected in parallel. Because the test circuit is an NEC test fixture for

inspection and because there is no optimum L value for the inspection fixture, the necessary L value is

created by connecting plural L1s in parallel. In actual application by the user, the optimum L value can be

obtained by using one chip inductor as described in 5.4.

Remark

Evaluation board

The following two types of evaluation boards are available for these ICs. Because the patterns on

these boards are used for an inspection fixture that easily confirms the characteristics of the ICs, and

because components cannot be mounted in the vicinity of the ICs, the pattern size is greater than the

actual size. This means that these patterns are not recommended patterns.

Table 5-1 shows the major differences of the two types of evaluation boards: TYPE1 and TYPE2.

Because TYPE1 can mount an external inductor to the

S

type circuit of the V

CC

line, it can evaluate

whether this inductor is provided or the dependency of the L value.

TYPE2 can evaluate whether the characteristics can be ensured by using the inductor of about 5 nH of

the power supply

S

type circuit as pattern L when the number of components is reduced. In addition,

because a V

CC

pin monitor line is provided, the leakage from the V

CC

pin can be also evaluated.

The constants of the mounted components for output matching and type differ depending on the

frequency used, and TYPE is not divided by the part number or frequency. When purchasing an

evaluation board, specify the type No. by referring to Table 5-1.

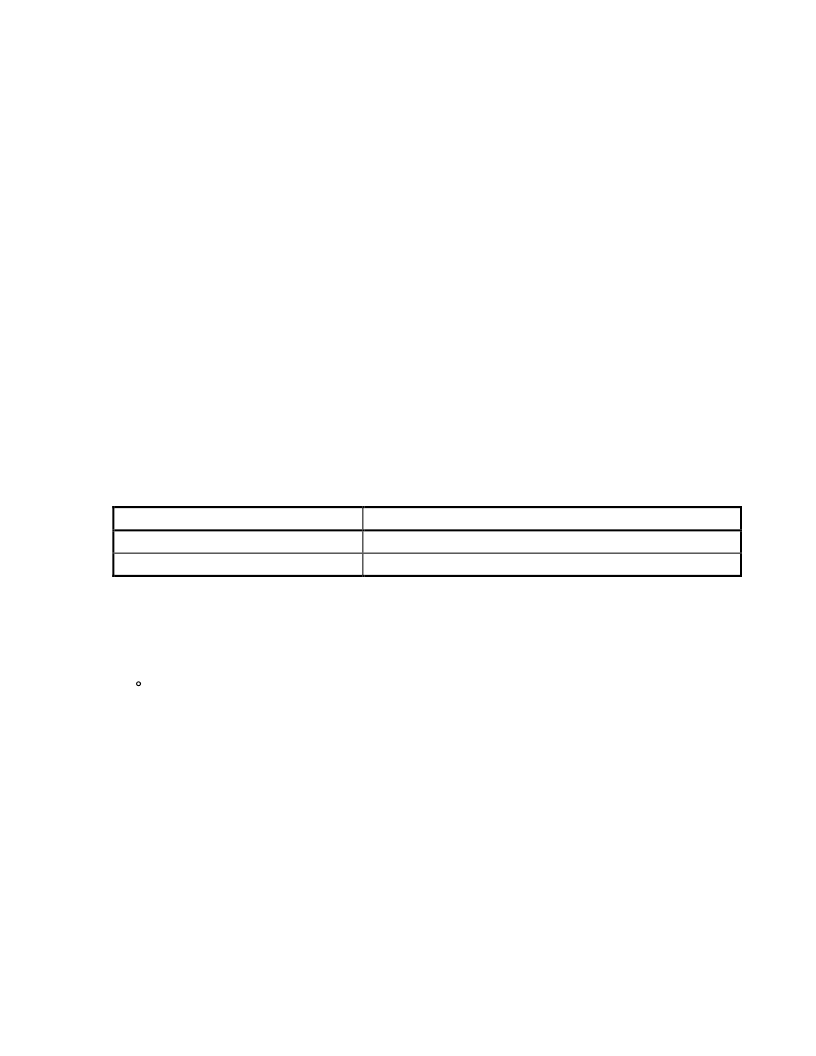

Table 5-1. Types of Evaluation Boards

Type Name (inscribed on pattern)

Features

P

PC8119/20T TYPE1

Can connect external inductor to

S

ype circuit of V

CC

line

P

PC8119/20T TYPE2

Pattern L equivalent to 5 nH is printed for

S

ype circuit of V

CC

line.

Notes on evaluation board (common to TYPE1 and TYPE 2)

(1) 35-

P

m thick copper patterning on both sides of 35

u

42

u

0.4 mm polyimide board

(2) GND pattern on rear side

(3) Solder-plated patterning side

(4)

{

: Through hole

Design the actual print pattern depending on the material of your board and frequency. For foot print and mount

pad dimensions, refer to

Semiconductor Device Mounting Technology Manual (C10535E).

5.4 Parameters for Matching Circuit Designing

The matching circuit constants shown in the Data Sheet are for the evaluation board also shown in the Data

Sheet. This evaluation board is for simple evaluation only and it is considered to be impossible to apply this board in

an actual system. For your reference for designing a matching circuit, Figure 5-3 shows the S parameter values

(MAG and ANG) of the

P

PC8119T and

P

PC8120T (without matching) and an input/output Smith chart. It is

recommended that matching be created based on the parameters at the maximum gain, so that the maximum gain of

these ICs are ensured. For this reason, the parameters shown in Figure 5-3 are at the maximum gain (changes in

the impedance at the minimum gain poses no problem to the actual application). Optimize the matching circuit

constants by considering these parameters and the mounting board element.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| P12C508 | 8-Pin, 8-Bit CMOS Microcontroller |

| P12 | ERSATZAKKU 12V |

| P1300SA | SIDACtor Device |

| P1100S | SIDACtor Device |

| P1100SCMC | solid state crowbar devices |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| P128/BL/10M | 制造商:Adaptaflex 功能描述:25MM POLYAMIDE(PI) CONDUI |

| P1281-0151-01KBAS | 制造商:Measurement Specialties Inc 功能描述:PT, 0-1000 BAR, SINGLE SENSOR - Bulk |

| P1281-0151-1KBAS | 制造商:Measurement Specialties Inc 功能描述:PT, 0-1000 BAR, SINGLE SENSOR - Bulk |

| P128-1CCSF | 制造商:Carlisle Interconnect Components 功能描述:BETWEEN SERIES ADAPTER |

| P128-2CCSF | 制造商:Carlisle Interconnect Components 功能描述:BETWEEN SERIES ADAPTER |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。