- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄4169 > XC5210-6PQ208C (Xilinx Inc)IC FPGA 324 CLB'S 208-PQFP PDF資料下載

參數(shù)資料

| 型號: | XC5210-6PQ208C |

| 廠商: | Xilinx Inc |

| 文件頁數(shù): | 8/73頁 |

| 文件大小: | 0K |

| 描述: | IC FPGA 324 CLB'S 208-PQFP |

| 產(chǎn)品變化通告: | XC1700 PROMs,XC5200,HQ,SCD Parts Discontinuation 19/Jul/2010 |

| 標準包裝: | 24 |

| 系列: | XC5200 |

| LAB/CLB數(shù): | 324 |

| 邏輯元件/單元數(shù): | 1296 |

| 輸入/輸出數(shù): | 164 |

| 門數(shù): | 16000 |

| 電源電壓: | 4.75 V ~ 5.25 V |

| 安裝類型: | 表面貼裝 |

| 工作溫度: | 0°C ~ 85°C |

| 封裝/外殼: | 208-BFQFP |

| 供應商設備封裝: | 208-PQFP(28x28) |

| 其它名稱: | 122-1149 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁當前第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁

R

XC5200 Series Field Programmable Gate Arrays

7-98

November 5, 1998 (Version 5.2)

VersaRing Input/Output Interface

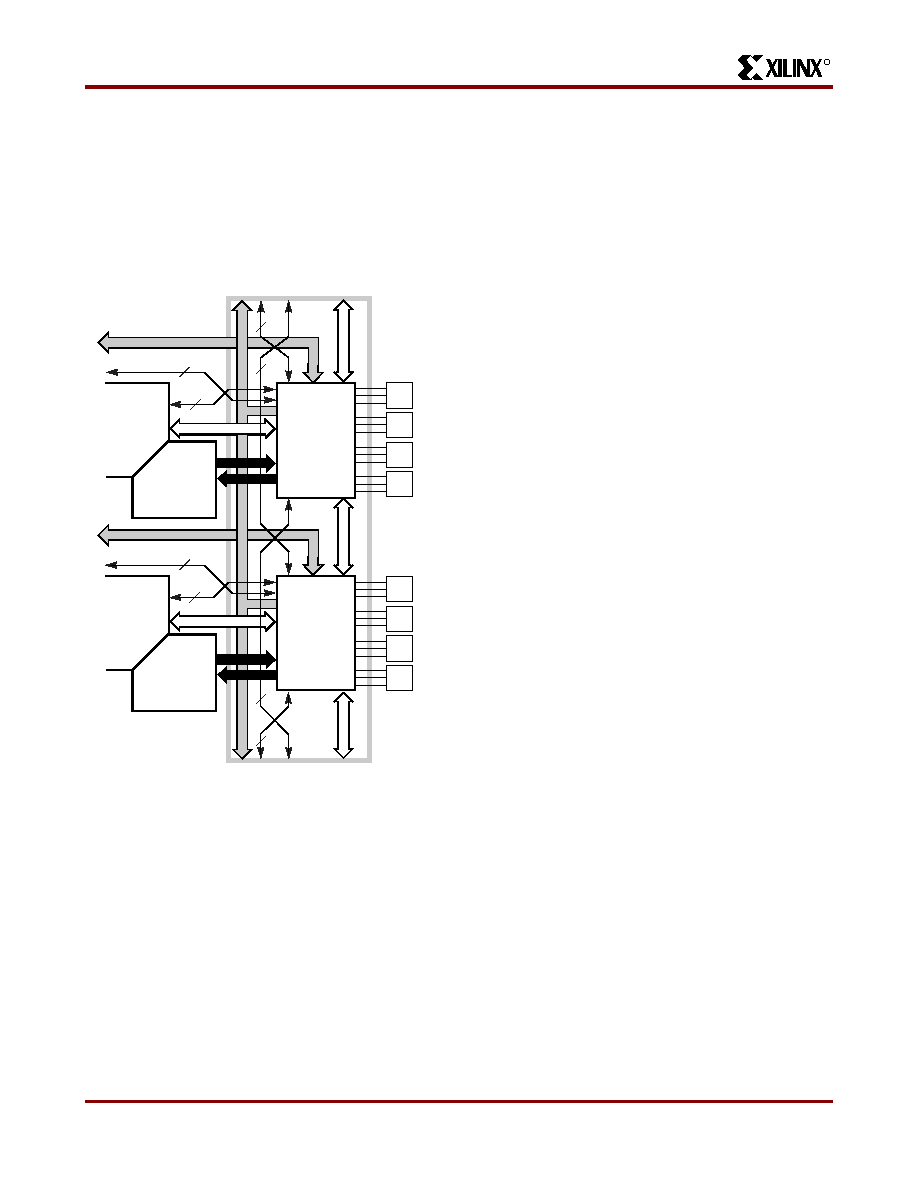

The VersaRing, shown in Figure 18, is positioned between

the core logic and the pad ring; it has all the routing

resources of a VersaBlock without the CLB logic. The Ver-

saRing decouples the core logic from the I/O pads. Each

VersaRing Cell provides up to four pad-cell connections on

one side, and connects directly to the CLB ports on the

other side.

Boundary Scan

The “bed of nails” has been the traditional method of testing

electronic assemblies. This approach has become less

appropriate, due to closer pin spacing and more sophisti-

cated assembly methods like surface-mount technology

and multi-layer boards. The IEEE boundary scan standard

1149.1 was developed to facilitate board-level testing of

electronic assemblies. Design and test engineers can

imbed a standard test logic structure in their device to

achieve high fault coverage for I/O and internal logic. This

structure is easily implemented with a four-pin interface on

any boundary scan-compatible IC. IEEE 1149.1-compatible

devices may be serial daisy-chained together, connected in

parallel, or a combination of the two.

XC5200 devices support all the mandatory boundary-scan

instructions specified in the IEEE standard 1149.1. A Test

Access Port (TAP) and registers are provided that imple-

ment the EXTEST, SAMPLE/PRELOAD, and BYPASS

instructions. The TAP can also support two USERCODE

instructions. When the boundary scan configuration option

is selected, three normal user I/O pins become dedicated

inputs for these functions. Another user output pin

becomes the dedicated boundary scan output.

Boundary-scan operation is independent of individual IOB

configuration and package type. All IOBs are treated as

independently controlled bidirectional pins, including any

unbonded IOBs. Retaining the bidirectional test capability

after configuration provides flexibility for interconnect test-

ing.

Also, internal signals can be captured during EXTEST by

connecting them to unbonded IOBs, or to the unused out-

puts in IOBs used as unidirectional input pins. This tech-

nique partially compensates for the lack of INTEST

support.

The user can serially load commands and data into these

devices to control the driving of their outputs and to exam-

ine their inputs. This method is an improvement over

bed-of-nails testing. It avoids the need to over-drive device

outputs, and it reduces the user interface to four pins. An

optional fifth pin, a reset for the control logic, is described in

the standard but is not implemented in Xilinx devices.

The dedicated on-chip logic implementing the IEEE 1149.1

functions includes a 16-state machine, an instruction regis-

ter and a number of data registers. The functional details

can be found in the IEEE 1149.1 specification and are also

discussed in the Xilinx application note XAPP 017:

“Bound-

ary Scan in XC4000 and XC5200 Series devices”

Figure 19 on page 99 is a diagram of the XC5200-Series

boundary scan logic. It includes three bits of Data Register

per IOB, the IEEE 1149.1 Test Access Port controller, and

the Instruction Register with decodes.

The public boundary-scan instructions are always available

prior to configuration. After configuration, the public instruc-

tions and any USERCODE instructions are only available if

specified in the design. While SAMPLE and BYPASS are

available during configuration, it is recommended that

boundary-scan operations not be performed during this

transitory period.

In addition to the test instructions outlined above, the

boundary-scan circuitry can be used to configure the FPGA

device, and to read back the configuration data.

All of the XC4000 boundary-scan modes are supported in

the XC5200 family. Three additional outputs for the User-

Register are provided (Reset, Update, and Shift), repre-

Figure 18: VersaRing I/O Interface

8

GRM

VersaBlock

8

VersaRing

2

4

8

4

10

2

GRM

VersaBlock

8

2

8

10

Interconnect

Pad

X5705

Product Obsolete or Under Obsolescence

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 88997-2 | CONTACT TIN SOLDER FLAT FLEX |

| ABC65DREI-S93 | CONN EDGECARD 130PS .100 EYELET |

| GMC22DTEF | CONN EDGECARD 44POS .100 EYELET |

| XC4005XL-09PQ208C | IC FPGA C-TEMP 3.3V 208-PQFP |

| ASC65DRTI | CONN EDGECARD 130PS .100 DIP SLD |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| XC5210-6PQ208C0167 | 制造商:Xilinx 功能描述: |

| XC5210-6PQ208I | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Field Programmable Gate Array (FPGA) |

| XC5210-6PQ240C | 功能描述:IC FPGA 324 CLB'S 240-PQFP RoHS:否 類別:集成電路 (IC) >> 嵌入式 - FPGA(現(xiàn)場可編程門陣列) 系列:XC5200 產(chǎn)品變化通告:XC4000(E,L) Discontinuation 01/April/2002 標準包裝:24 系列:XC4000E/X LAB/CLB數(shù):100 邏輯元件/單元數(shù):238 RAM 位總計:3200 輸入/輸出數(shù):80 門數(shù):3000 電源電壓:4.5 V ~ 5.5 V 安裝類型:表面貼裝 工作溫度:-40°C ~ 100°C 封裝/外殼:120-BCBGA 供應商設備封裝:120-CPGA(34.55x34.55) |

| XC5210-6PQ240I | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Field Programmable Gate Array (FPGA) |

| XC5210-6PQG208C | 制造商:Xilinx 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復。